Raw material cutting device for activated carbon production

A technology of activated carbon production and cutting device, which is applied to presses, grain processing, manufacturing tools, etc., can solve the problems of waste of straw resources, pollution of the environment, and winding of straws around the rotating shaft, and achieve the effect of ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

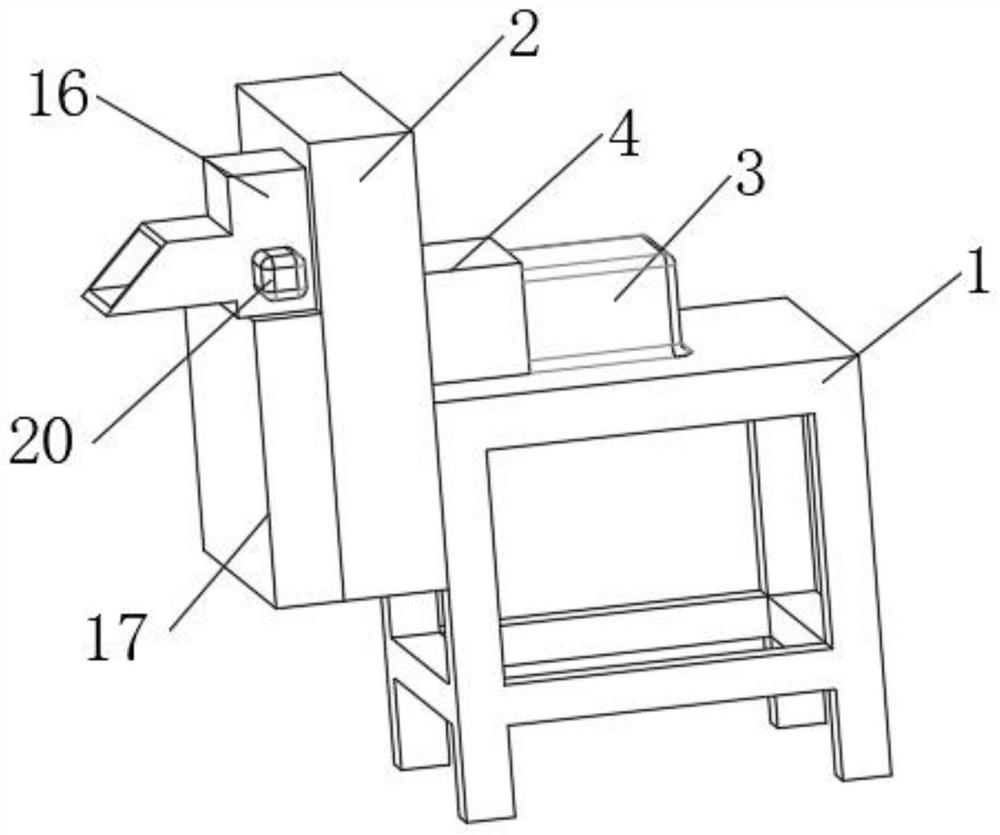

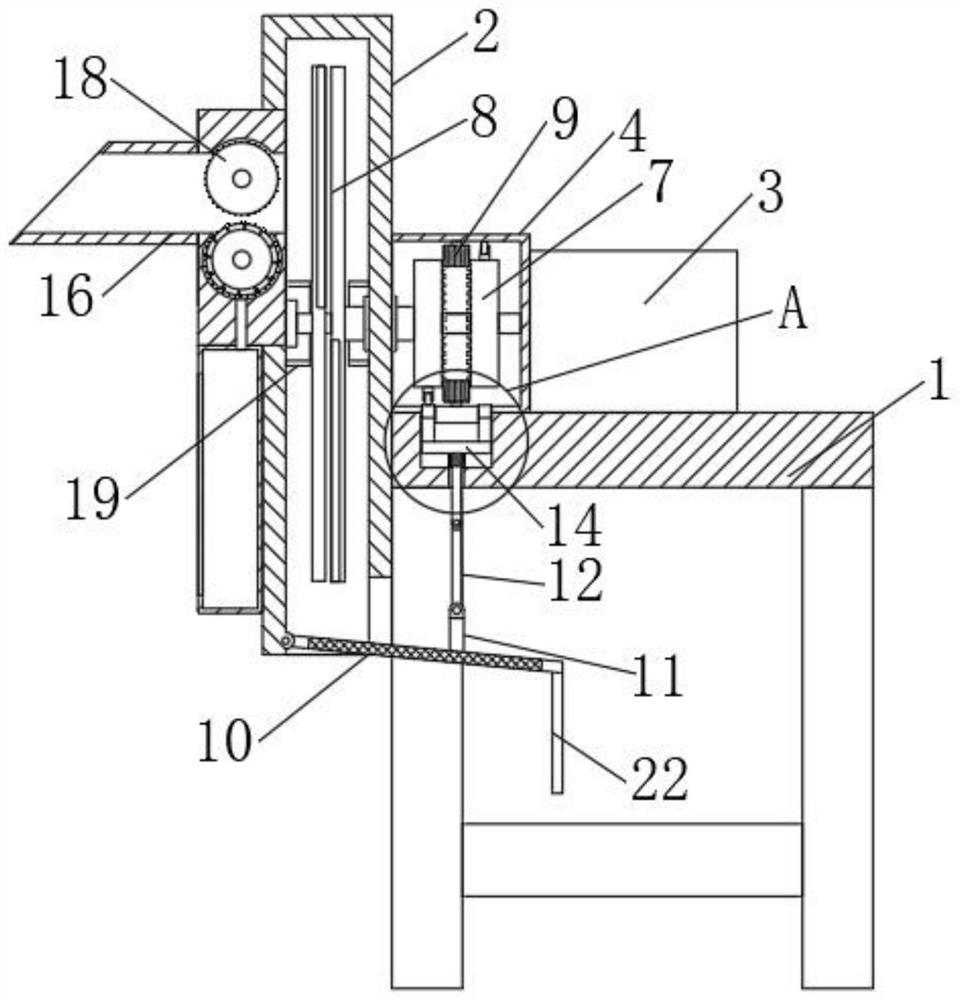

[0028] refer to Figure 1-4 , a raw material cutting device for activated carbon production, including a cutting assembly, a screening assembly and a feeding assembly, the cutting assembly includes a support frame 1, the side of the support frame 1 is fixedly connected with a cutting box 2, and the upper surface of the support frame 1 is fixedly connected respectively There is a drive motor 3 and a transmission box 4. The output end of the drive motor 3 is fixedly connected with a rotating shaft 5, and the outer surface of the rotating shaft 5 is rotatably connected with a rotating tube 6. The inner wall of the box 2, and the inner walls of both sides of the cutting box 2 are fixedly connected with protective rings 19 .

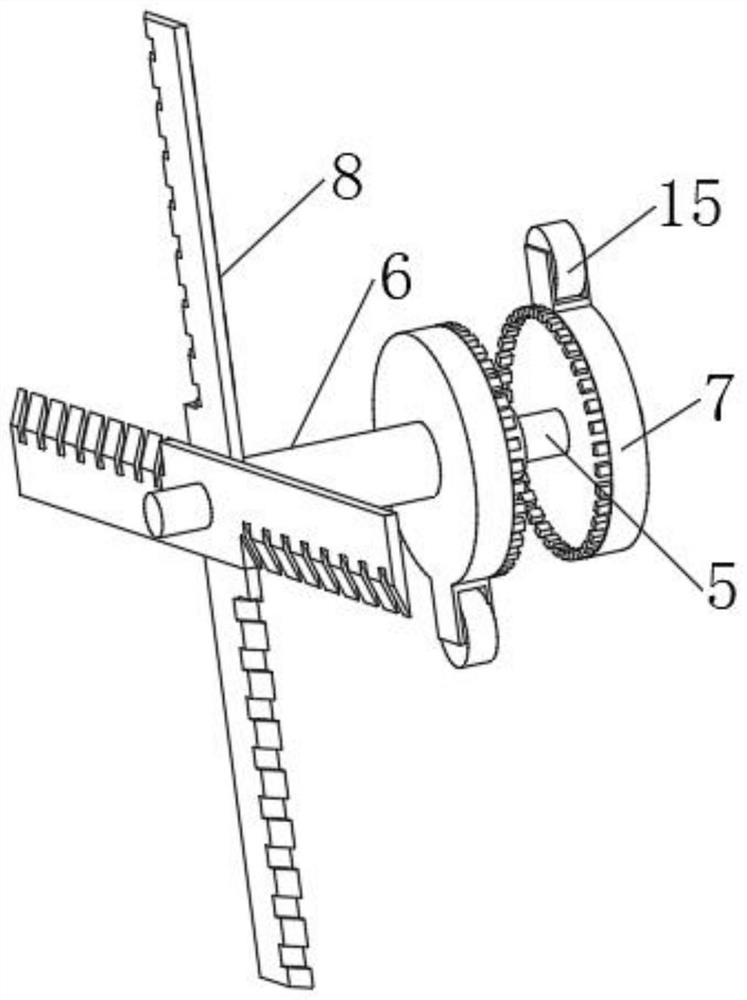

[0029] The outer surfaces of the rotating shaft 5 and the rotating tube 6 are fixedly connected with a driving gear 7 and a cutting knife 8, and the blade surface of the cutting knife 8 is provided with a saw-toothed cutting groove, and the inner top wall and...

Embodiment 2

[0034] refer to Figure 5 , the screening assembly includes a screen 10 that is rotatably connected to the inner sidewall of the cutting box 2, the side of the screen 10 is fixedly connected with a baffle plate 22, the upper surface of the screen 10 is fixedly connected with a frame 11, and the upper surface of the frame 11 is Rotationally connected with a rotating rod 12, the top of the rotating rod 12 is rotatably connected with a support rod 13, and the top of the support rod 13 is fixedly connected with a flat-shaped bracket 14, and the outer surfaces of the two driving gears 7 are connected with a scroll wheel 15 through a rotating seat. , the upper surface of the support frame 1 is provided with a sliding groove compatible with the stent 14, the outer surface of the support rod 13 is provided with a return spring 21, and the bottom end of the return spring 21 is fixedly connected to the inner bottom wall of the sliding groove. The top of the back-moving spring 21 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com