Polyisocyanate prepolymer, rosin modified epoxy resin and conductive ink

A technology of polyisocyanate and isocyanate, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of high resistivity and large thickness of conductive coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

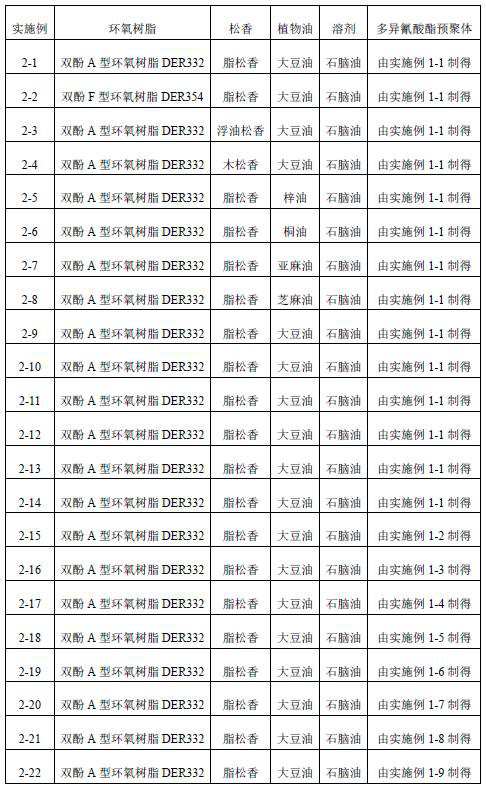

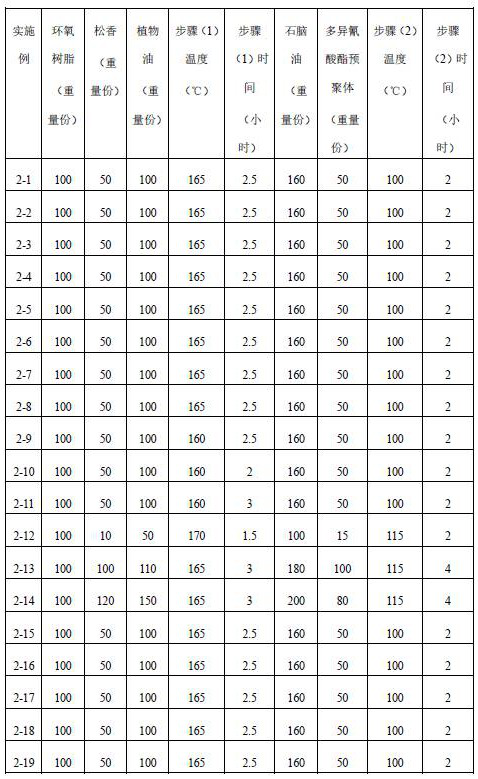

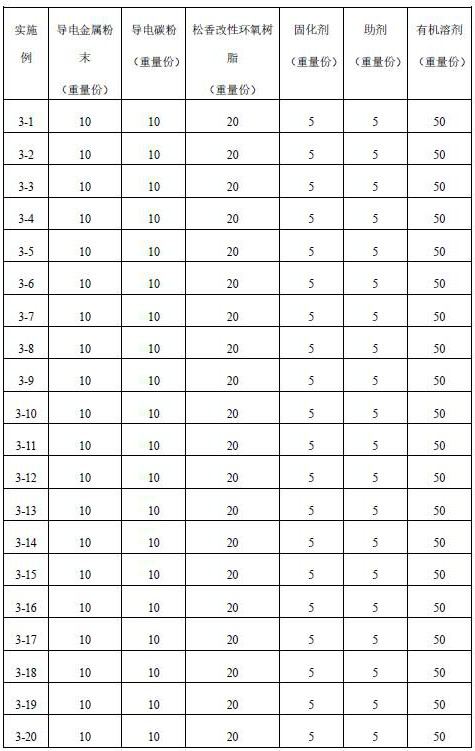

Examples

Embodiment 1

[0049] The preparation of embodiment 1 polyisocyanate prepolymer

Embodiment 1-1

[0051] Add 4 kg of polyoxypropylene diol 2000 and 1 kg of polyoxypropylene triol 1000 to a four-necked flask equipped with a stirrer, a thermometer, and a nitrogen protection device after removing water, and add 5.5 kg of isophorone diisocyanate and Diphenylmethane-4,4'-diisocyanate (mass ratio 1:1), mixed evenly, heated to 80°C, reacted under nitrogen atmosphere for 3 hours, cooled to room temperature, and obtained polyisocyanate prepolymer.

Embodiment 1-2

[0053] The mass ratio of isophorone diisocyanate and diphenylmethane-4,4'-diisocyanate was replaced from 1:1 to 3:1, and the rest was the same as in Example 1 to prepare a polyisocyanate prepolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com