Preparation method of peppermint essence

A technology of peppermint flavor and menthol, which is applied in the directions of essential oils/spice, fat generation, etc., can solve the problems of insufficient mellow and long-lasting fragrance of the finished product, and achieve the effects of mellow flavor, slow release and good production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

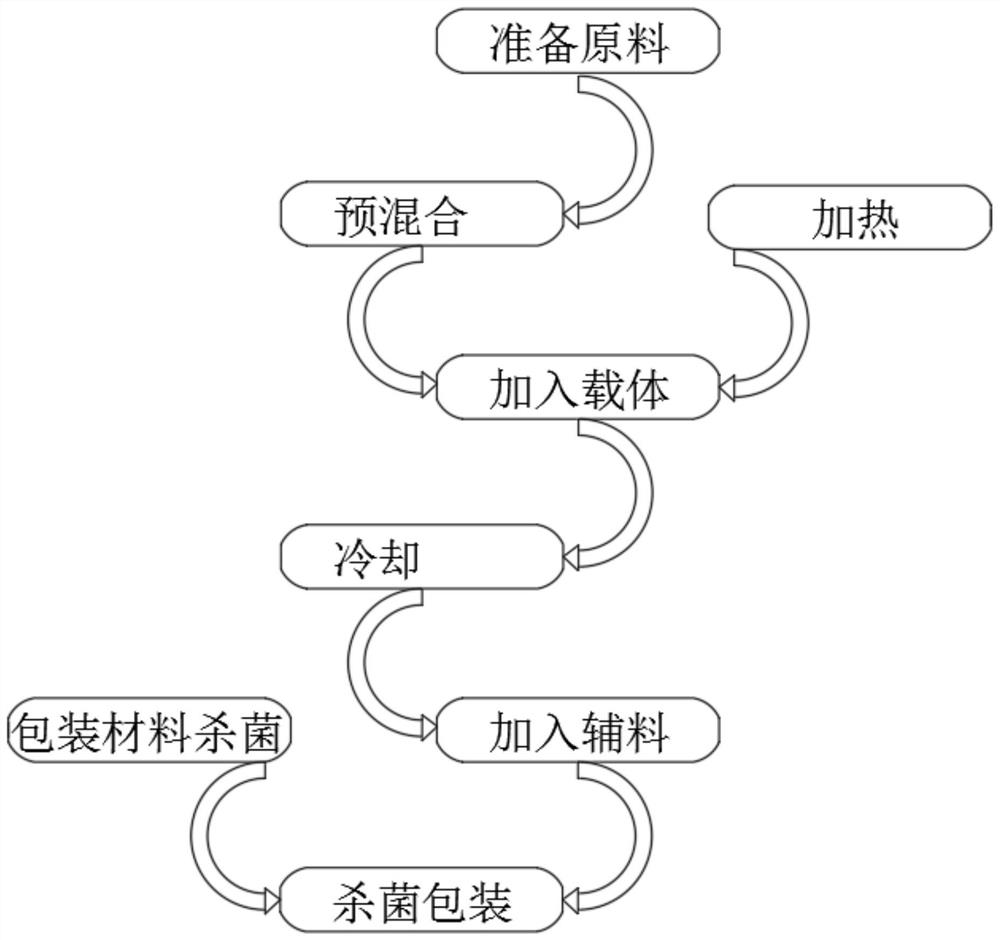

[0030] refer to figure 1 , a preparation method of peppermint essence, comprising the following steps:

[0031] S1: Prepare raw materials, 55 parts of natural menthol, 30 parts of mint oil, 15 parts of mint crude oil, 3 parts of spearmint oil, 3 parts of thyme oil, 3 parts of cooling agent, 4 parts of eucalyptus oil, 4 parts of anethole, 2 parts of clove oil, 73 parts of solvent, and 28 parts of carrier. The ratio of raw materials is reasonable and the cost is low. The mint essence produced is refreshing, with fresh and refreshing breath and mellow fragrance. Improve the durability of the cool feeling released by mint essence, which has good production efficiency;

[0032] S2: pre-mixing, adding natural menthol, mint oil, peppermint crude oil, spearmint oil, thyme oil, eucalyptus oil, and clove oil into a mixing tank for stirring and pre-mixing, and the mixing time is 30 minutes;

[0033] S3: Add the carrier, add the carrier into the mixing tank for continuous mixing, heat d...

Embodiment 2

[0040] refer to figure 1 , a preparation method of peppermint essence, comprising the following steps:

[0041] S1: Prepare raw materials, 56 parts of natural menthol, 30 parts of peppermint oil, 20 parts of mint crude oil, 4 parts of spearmint oil, 2.5 parts of thyme oil, 3 parts of cooling agent, 3 parts of eucalyptus oil, 4 parts of anethole, 1 part of clove oil, 73 parts of solvent, and 28 parts of carrier. The proportion of raw materials is reasonable and the cost is low. The mint essence produced is refreshing, with fresh breath and mellow fragrance. The synergistic effect of each raw material further exerts the advantages of each component. Improve the durability of the cool feeling released by mint essence, which has good production efficiency;

[0042] S2: Pre-mixing, adding natural menthol, mint oil, peppermint crude oil, spearmint oil, thyme oil, eucalyptus oil, and clove oil into a mixing tank for stirring and pre-mixing, and the mixing time is 30 minutes;

[004...

Embodiment 3

[0050] refer to figure 1 , a preparation method of peppermint essence, comprising the following steps:

[0051] S1: Prepare raw materials, 55 parts of natural menthol, 30 parts of mint oil, 15 parts of mint crude oil, 3 parts of spearmint oil, 3 parts of thyme oil, 3.5 parts of cooling agent, 5 parts of eucalyptus oil, 4 parts of anethole, 1 part of clove oil, 75 parts of solvent, and 25 parts of carrier. The proportion of raw materials is reasonable and the cost is low. The mint essence produced is refreshing, the breath is fresh and refreshing, and the fragrance is mellow. Improve the durability of the cool feeling released by mint essence, which has good production efficiency;

[0052] S2: pre-mixing, adding natural menthol, mint oil, peppermint crude oil, spearmint oil, thyme oil, eucalyptus oil, and clove oil into a mixing tank for stirring and pre-mixing, and the mixing time is 30 minutes;

[0053] S3: Add the carrier, add the carrier into the mixing tank for continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com