Chromium-based high-nitrogen alloy cushion block for silicon steel high-temperature heating furnace and preparation method of chromium-based high-nitrogen alloy cushion block

A high-temperature heating, high-nitrogen alloy technology, used in heat treatment furnaces, heat treatment equipment, metal processing equipment, etc., can solve problems such as the reduction of limited resources, improve adhesion, improve high temperature oxidation resistance, and improve crevice corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment further illustrate the present invention.

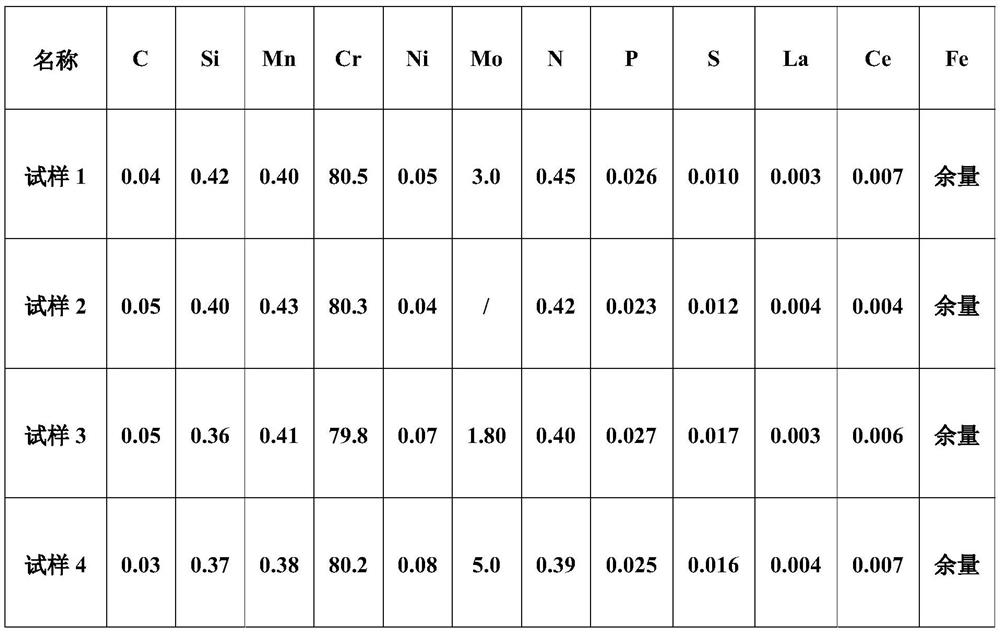

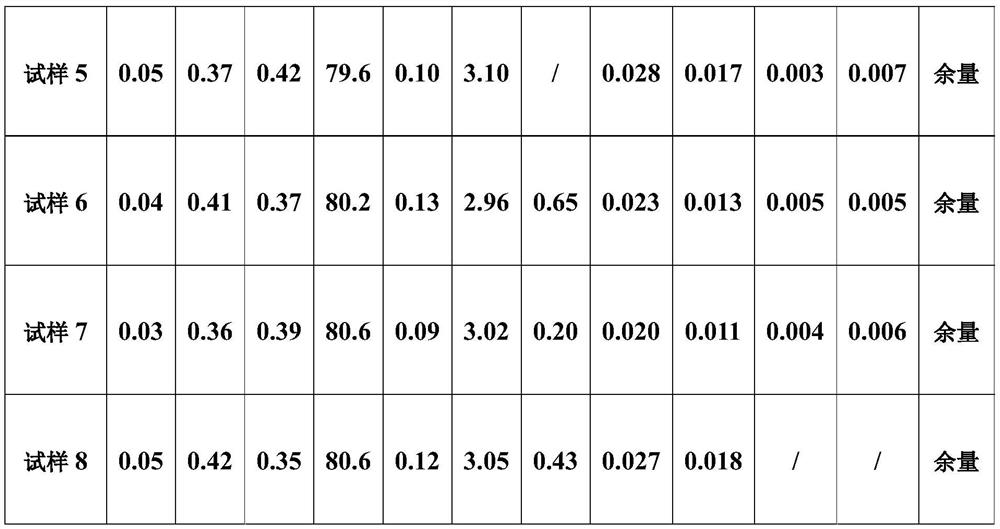

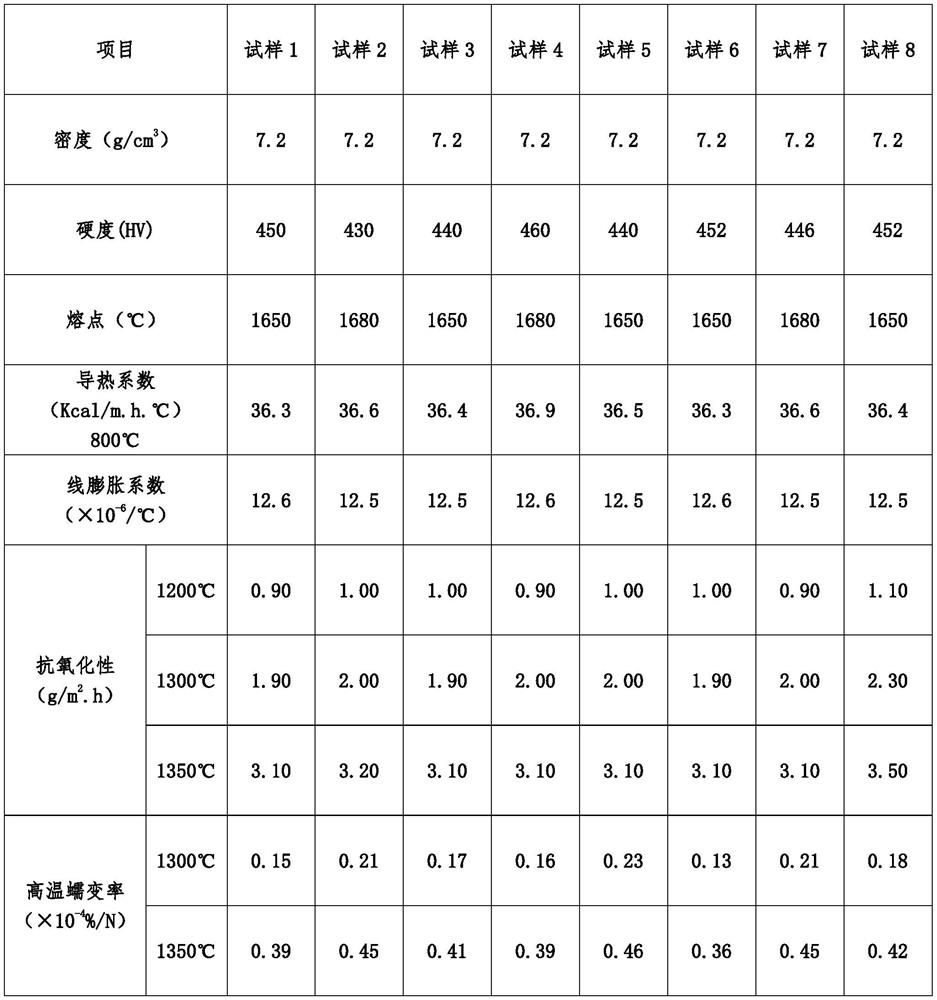

[0027] The eight embodiments of the present invention correspond to the preparation of heat-resistant pads from sample 1 to sample 8 in Table 1, respectively, and are casted according to the specific alloy composition in Table 1.

[0028] Table 1 sample chemical composition (mass %)

[0029]

[0030]

[0031] Among them, the difference between sample 2, sample 3 and sample 4 and sample 1 is mainly reflected in the change of Mo content, and the difference between sample 5, sample 6 and sample 7 and sample 1 is mainly reflected in the content of N The content changes, and the difference between sample 8 and sample 1 is mainly reflected in whether rare earth elements (La and Ce) are added.

[0032] The above-mentioned chromium-based high-nitrogen alloy heat-resistant pads for silicon steel high-temperature heating furnaces are all prepared by hot-melt method, and the preparation steps a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com