Full-mechanized construction operation vehicle for layered surrounding rock tunnel

A technology for operating vehicles and surrounding rocks, applied in tunnels, tunnel linings, safety devices, etc., can solve the problems of difficulty in ensuring the safety of construction personnel, long time-consuming processes, and high safety risks, and achieve time and cost savings for ventilation and dust reduction. Support strength and support timing, and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

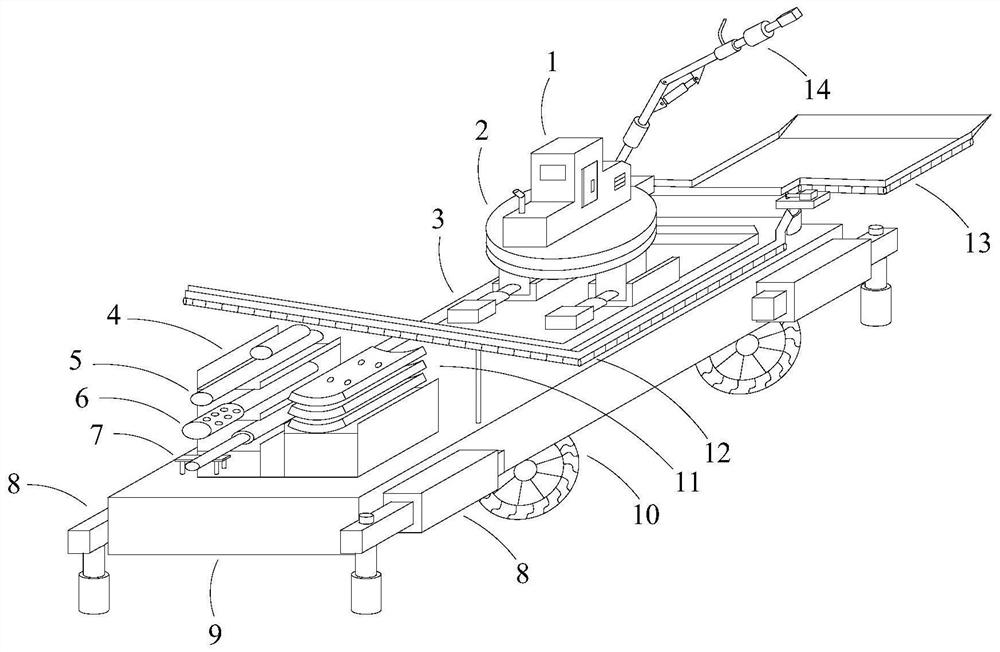

[0055] In this embodiment, a fully mechanized construction operation vehicle for layered surrounding rock tunnels is disclosed, including a vehicle body, on which a control room 1, an operating arm, a moving mechanism, a spoil treatment system and an installation head system are arranged;

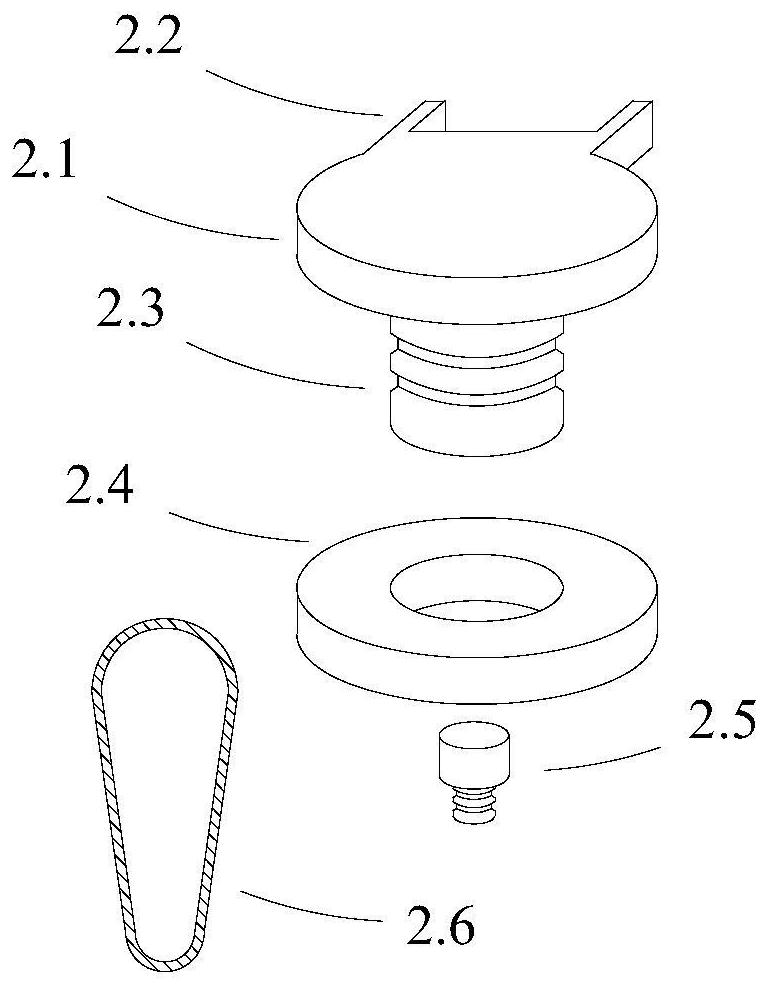

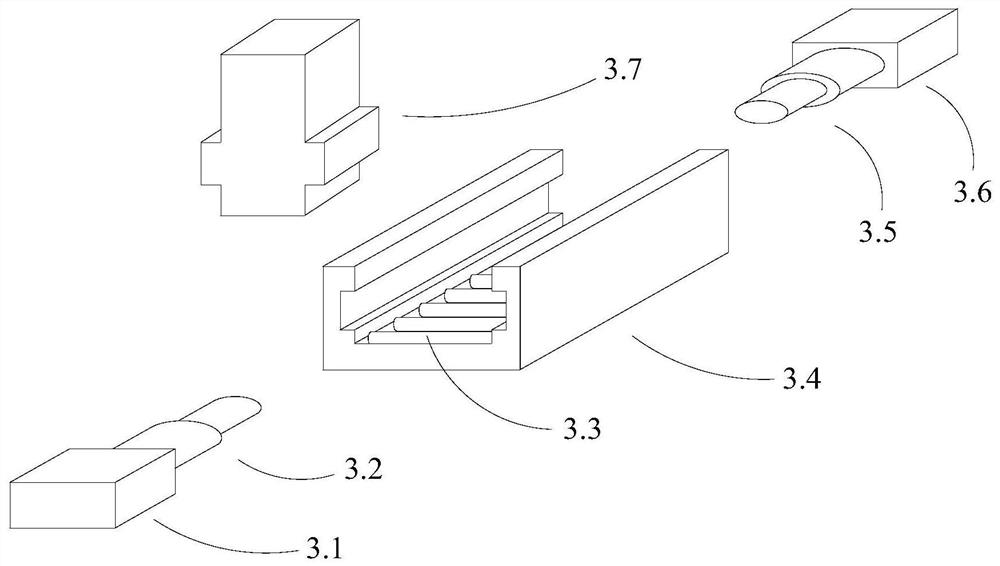

[0056] The control room 1 and the operating arm are all arranged on a moving mechanism, and the moving mechanism includes a turntable 2 and a sliding mechanism 3, and the turntable 2 is arranged on the sliding mechanism 3, and the control room 1 and the operation The arm is set on the turntable 2;

[0057] The waste slag processing system is used to receive the waste slag by using the waste slag receiving bucket, and transport the waste slag to the trumpet-shaped hopper by the conveyor belt inside the bucket. Through the waste slag transport system, the waste slag in the bucket is gradually lifted to the body of the slag discharge vehicle;

[0058] The installation head system is used to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com