Automatic frying pan

A frying pan, automatic technology, applied in the direction of cooking utensil lids, inserts, cooking utensils, etc., can solve the problems of sticky bottom, flat ingredients sticking to the bottom of the pot, and difficult cleaning of the stir-frying device, so as to reduce production costs , Improve cooking efficiency and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

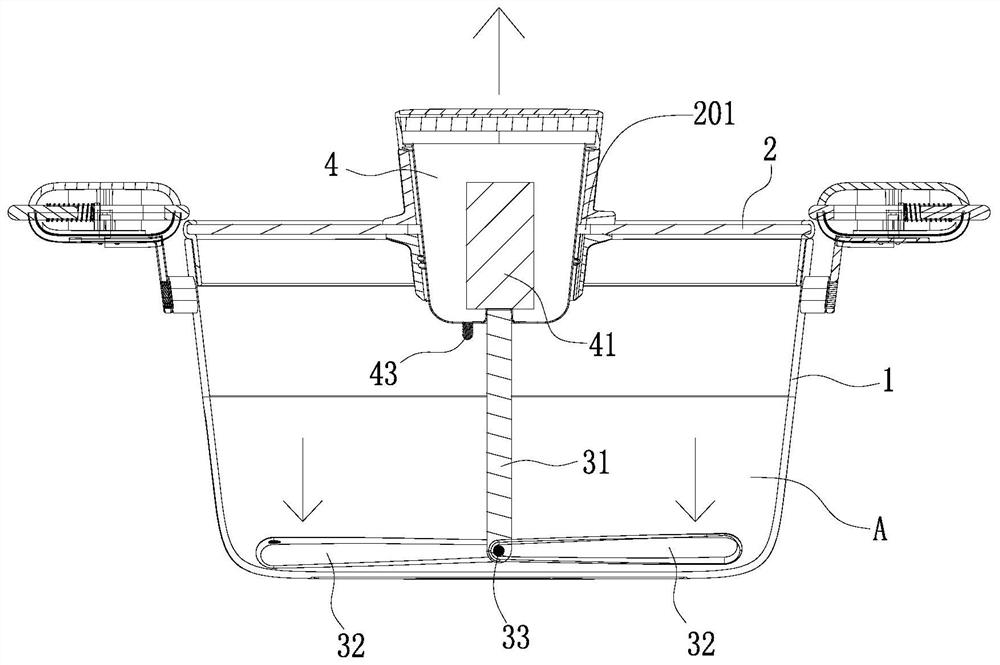

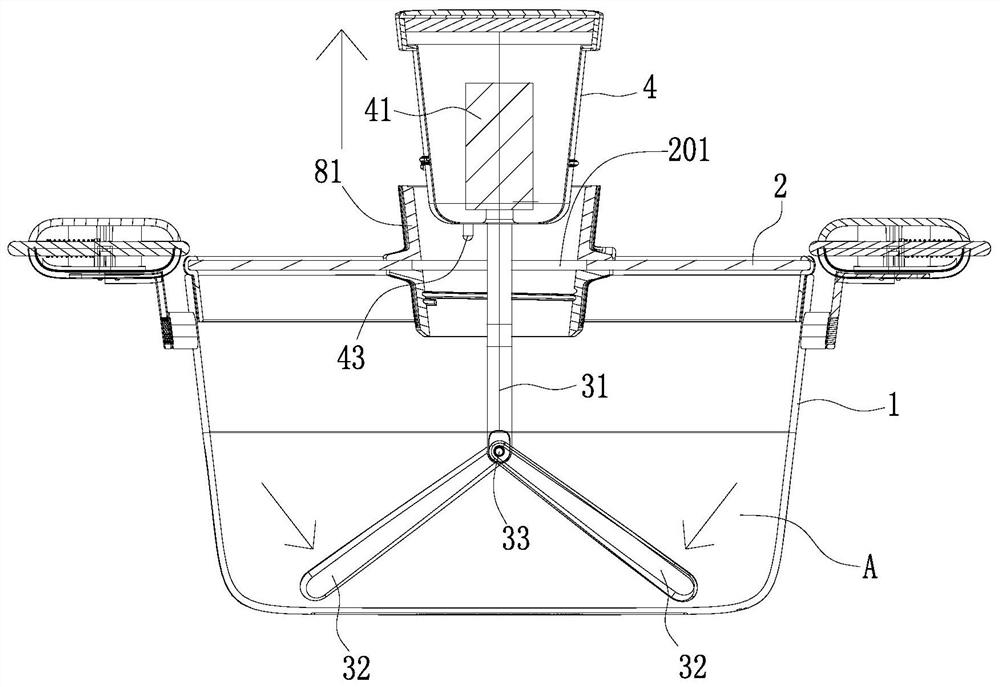

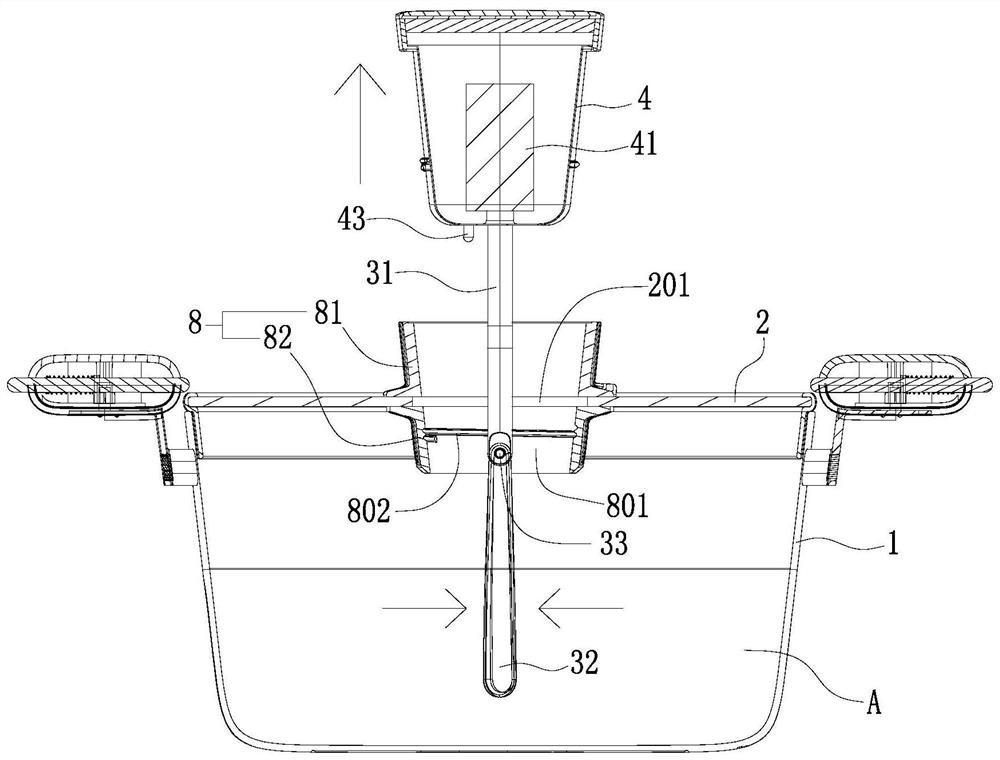

[0046] Such as Figure 1 to Figure 13As shown, an automatic cooking pot includes a pot body 1 and a pot cover 2, the pot cover 2 cooperates with the pot body 1 to form a cooking cavity A, and the stirrer head 4 with a built-in motor 41 is detachably installed on the pot cover 2 , the cooking chamber A is provided with a stirring assembly pivotally connected to the output end of the motor 41, the stirring assembly includes a stirring shaft 31 arranged in the cooking chamber A, the bottom end of the stirring shaft 31 is connected with at least one blade along the vertical direction The stirring paddle 32 that swings freely, the pot cover 2 is provided with an inlet and outlet 201 corresponding to the stirring shaft 31, and the stirring assembly can pass in and out of the cooking chamber A through the inlet and outlet 201, and the stirring blade 32 affecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com