A method for predicting tool wear and remaining life

A technology for tool wear and life prediction, applied in neural learning methods, genetic laws, manufacturing tools, etc., can solve the problem that it is difficult to guarantee the prediction accuracy with a single information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Embodiment of the present invention will be further described below in conjunction with accompanying drawing:

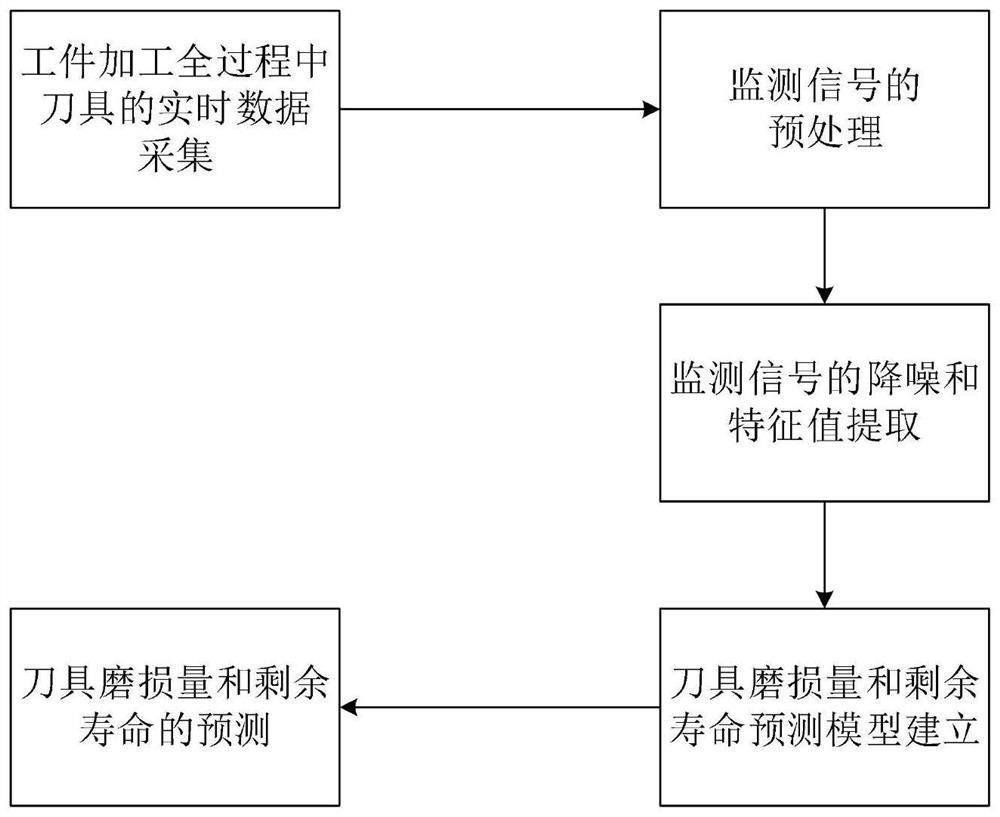

[0082] In the embodiment of the present invention, the improved Elman neural network tool wear amount and remaining life prediction method based on multi-sensor information fusion, the method flow chart is as follows figure 1 shown, including the following steps:

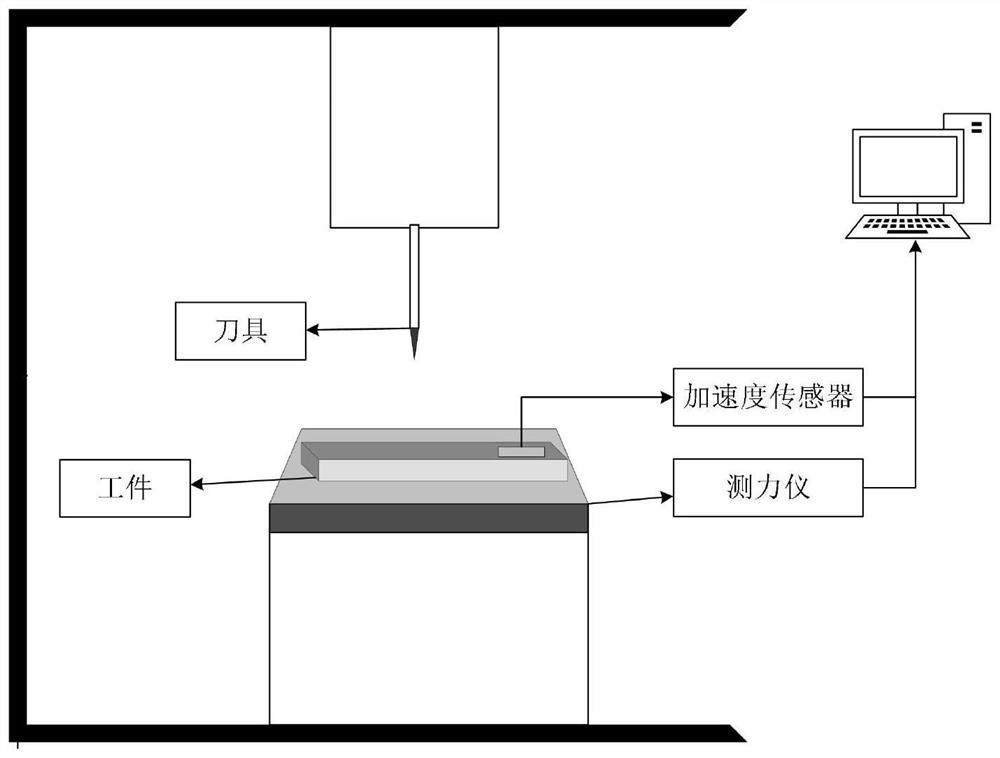

[0083] Step 1), build an experimental platform, and obtain real-time monitoring data reflecting the state of the tool;

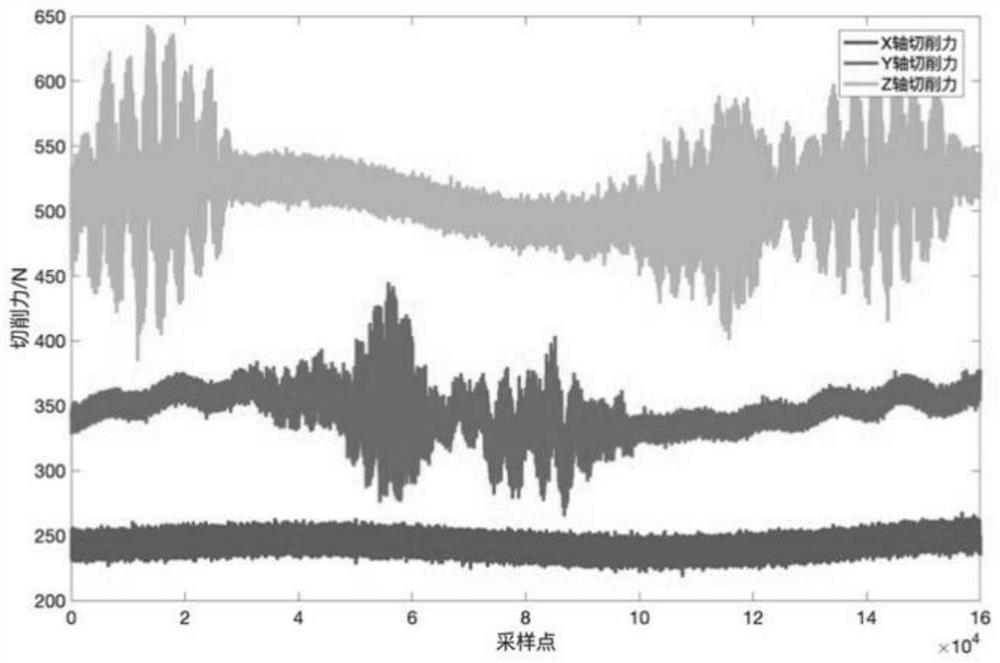

[0084] The workbench is built as figure 2 shown. The vibration signal of this experiment is collected by IEPE piezoelectric acceleration sensor; the cutting force signal is collected by Kistler9225B three-way dynamometer. The vibration signal is generated because the tool is in contact with the workpiece during processing, so the acceleration sensor is installed on the workpiece; the cutting force signal is the force applied by the tool to the workpiece for cutting, so the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com