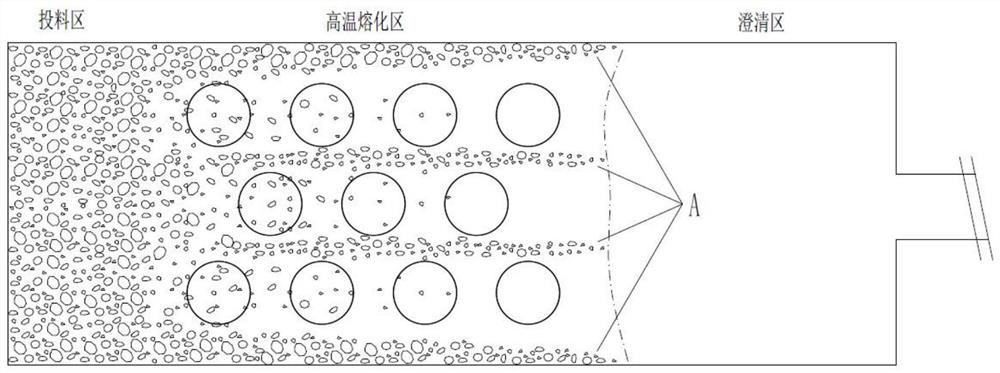

Rotary combustion device, kiln and rotary combustion method of kiln

A combustion device and kiln technology, applied in combustion methods, combustion equipment, furnaces, etc., can solve problems such as temperature rise in high-temperature melting areas, impact of batch materials and glass liquid surfaces, batch materials cannot be completely melted, etc., and achieve hot spot temperature drop , Improve the fire coverage area, which is conducive to the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present disclosure with reference to the accompanying drawings in the embodiments of the present disclosure. Apparently, the described embodiments are part of the embodiments of the present disclosure, not all of them. Based on the embodiments in the present disclosure, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present disclosure. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

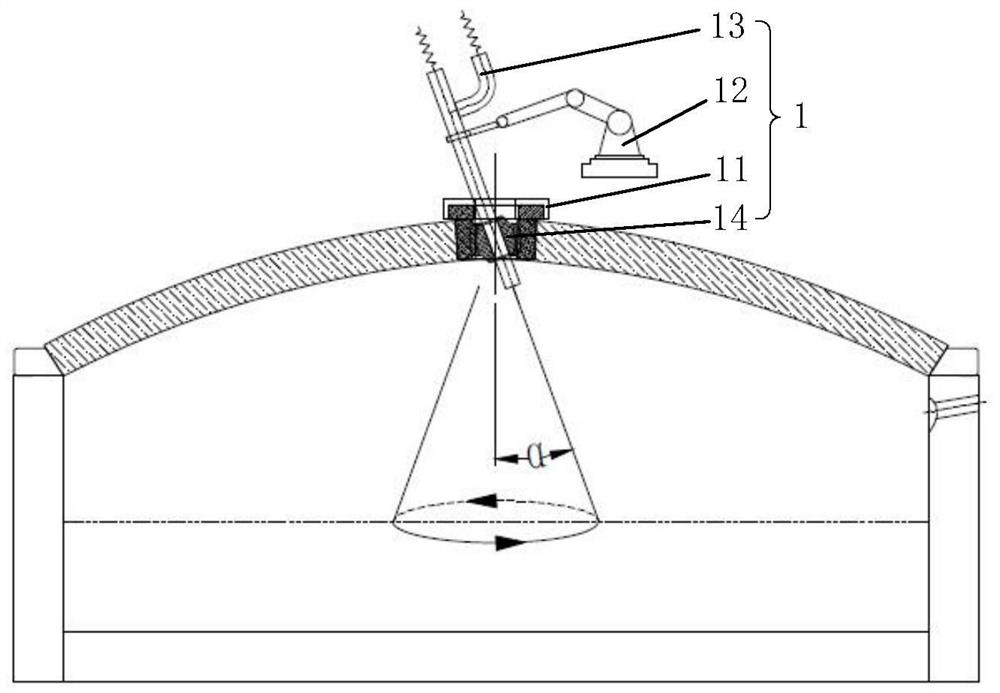

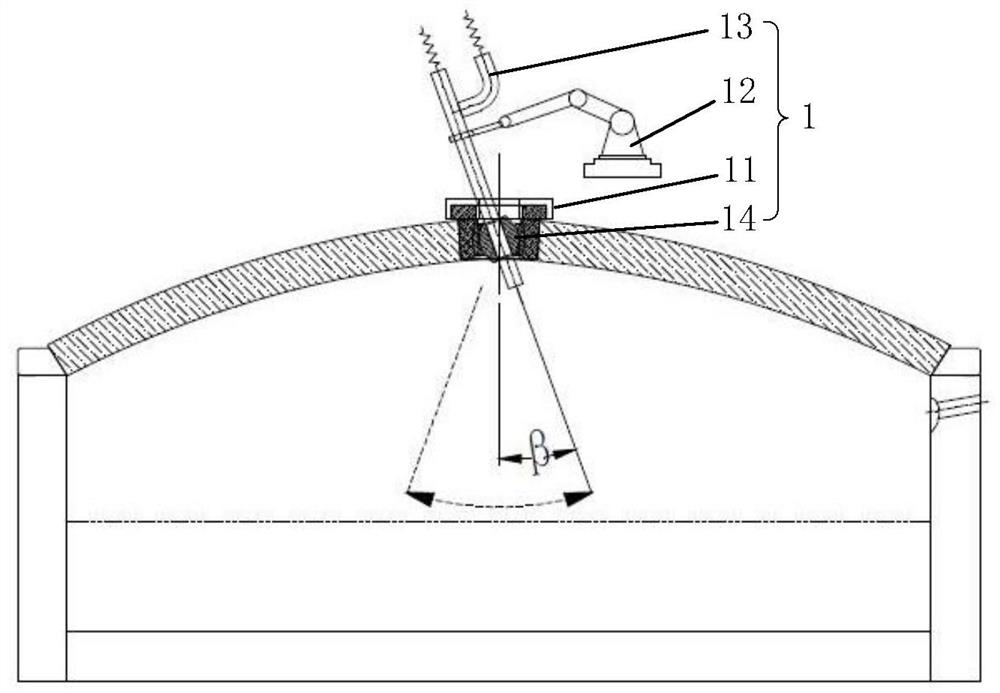

[0027] The disclosure adopts a rotating combustion device to dynamically burn the materials in the kiln, and uses a multi-degree-of-freedom adjustment arm to rotate or swing the tubular burner. The action is fast and efficient, and the adjustment range is large. Realize the largest r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com