Preparation method of azo pigment

An azo pigment and diazo liquid technology, applied in the field of pigment production, can solve the problems of poor thermal stability, decreased quality performance, complicated preparation process, etc., and achieve the effects of enhancing thermal stability and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

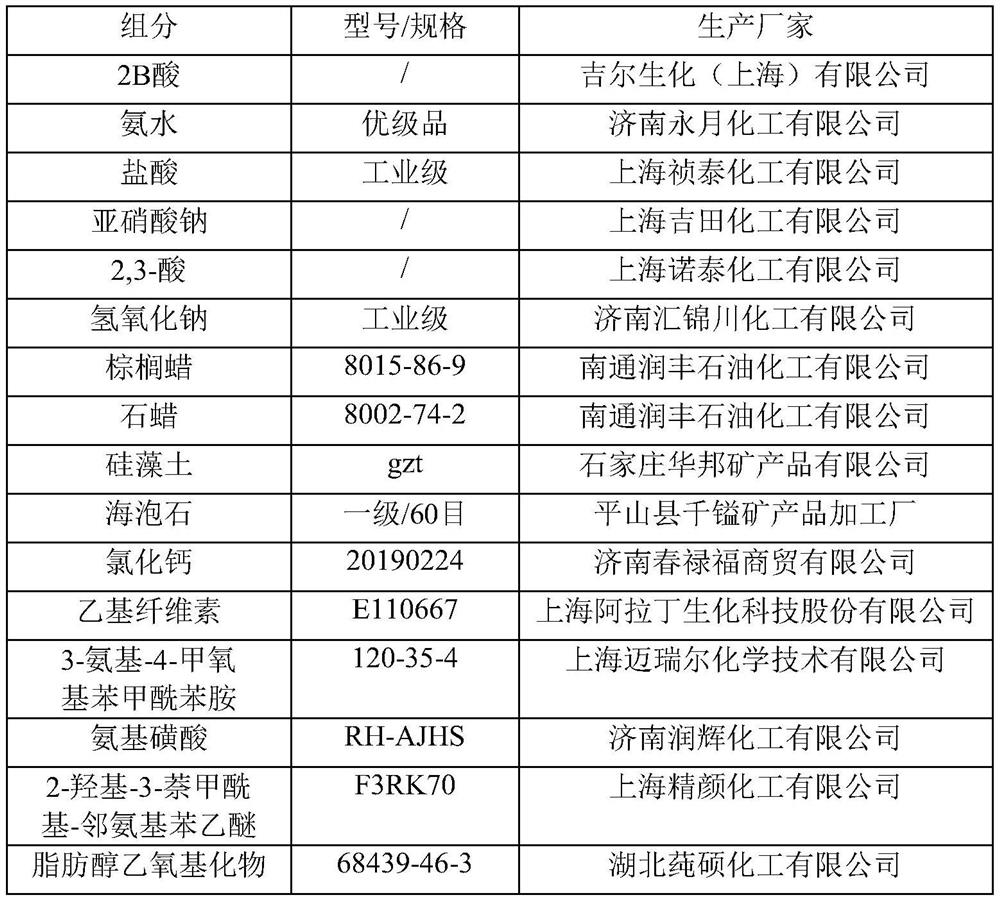

Examples

Embodiment 1

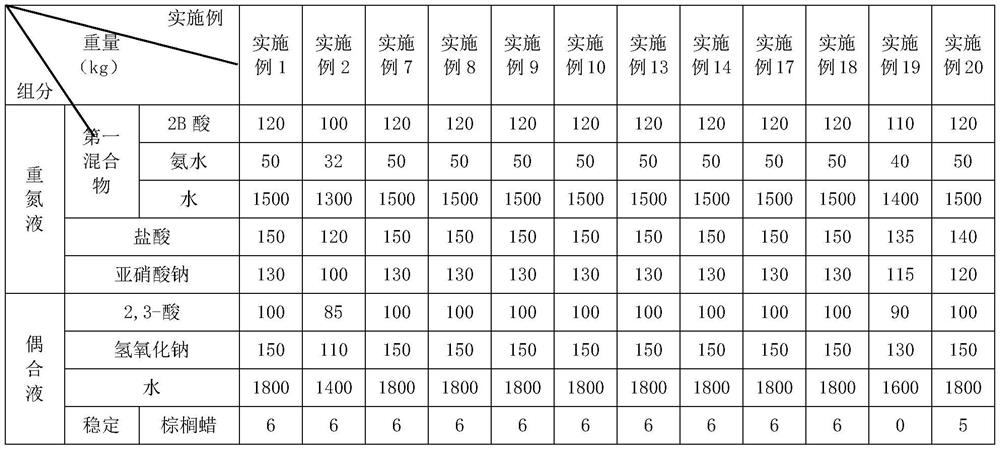

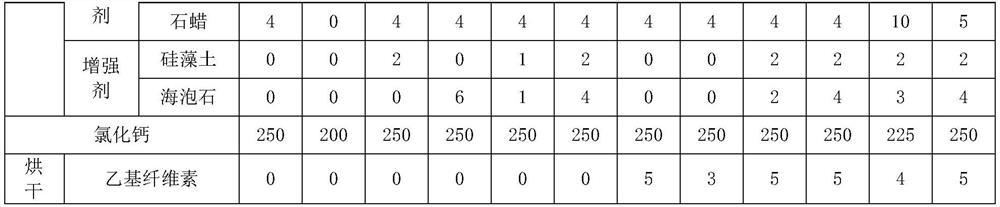

[0039] A kind of azo pigment, the concrete component that comprises and weight are as shown in table 2, are made by following steps:

[0040] S1: 2B acid, 20% by weight of ammonia and water are mixed and stirred at a stirring speed of 1000r / min, and the 2B acid is completely dissolved to obtain the first mixture;

[0041] S2: Add 30% by weight hydrochloric acid to the first mixture and mix and stir at a stirring speed of 500r / min. After stirring evenly, add ice cubes to cool down to 10°C, then add 30% by weight of sodium nitrite aqueous solution, add The speed is 12 parts by weight / min, the stirring speed is 800r / min, stir evenly, and obtain the diazonium liquid after keeping for 30min;

[0042] S3: Mix and stir 2,3-acid, 20% by weight sodium hydroxide and water at a stirring speed of 1000r / min. After stirring evenly, add a stabilizer and continue stirring at a stirring speed of 1000r / min. After stirring, a coupling liquid is obtained ;

[0043] S4: the diazonium liquid and ...

Embodiment 2

[0045] Embodiment 2: a kind of azo pigment, the difference with embodiment 1 is that concrete components and weight are different, and the concrete components and weight that comprise are as shown in table 2, comprise the following steps:

[0046] S1: 2B acid, 25% by weight of ammonia and water are mixed and stirred, the stirring speed is 1000r / min, and the 2B acid is completely dissolved to obtain the first mixture;

[0047] S2: Add 40% by weight of hydrochloric acid to the first mixture and mix and stir at a stirring speed of 500r / min. After stirring evenly, add ice cubes and cool down to 0°C, then add 35% by weight of sodium nitrite aqueous solution, add The speed is 12 parts by weight / min, the stirring speed is 800r / min, stir evenly, and obtain the diazonium liquid after keeping for 50min;

[0048] S3: Mix and stir 2,3-acid, 30% by weight sodium hydroxide and water at a stirring speed of 1000r / min. After stirring evenly, add a stabilizer and continue stirring at a stirring...

Embodiment 3

[0051] Embodiment 3: a kind of azo pigment, the difference with embodiment 1 is that in step S2, ice cubes are added to the first mixture, and the temperature is lowered to 7°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com