High-thermal-conductivity aluminum alloy material for semi-solid rheo-die casting and preparation method of high-thermal-conductivity aluminum alloy material

An aluminum alloy material and semi-solid rheological technology, which is applied in the field of alloy materials, can solve the problems of unsatisfactory comprehensive performance of aluminum alloys, achieve good casting fluidity, good die-casting effect, and reduce hydrogen content and slag content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

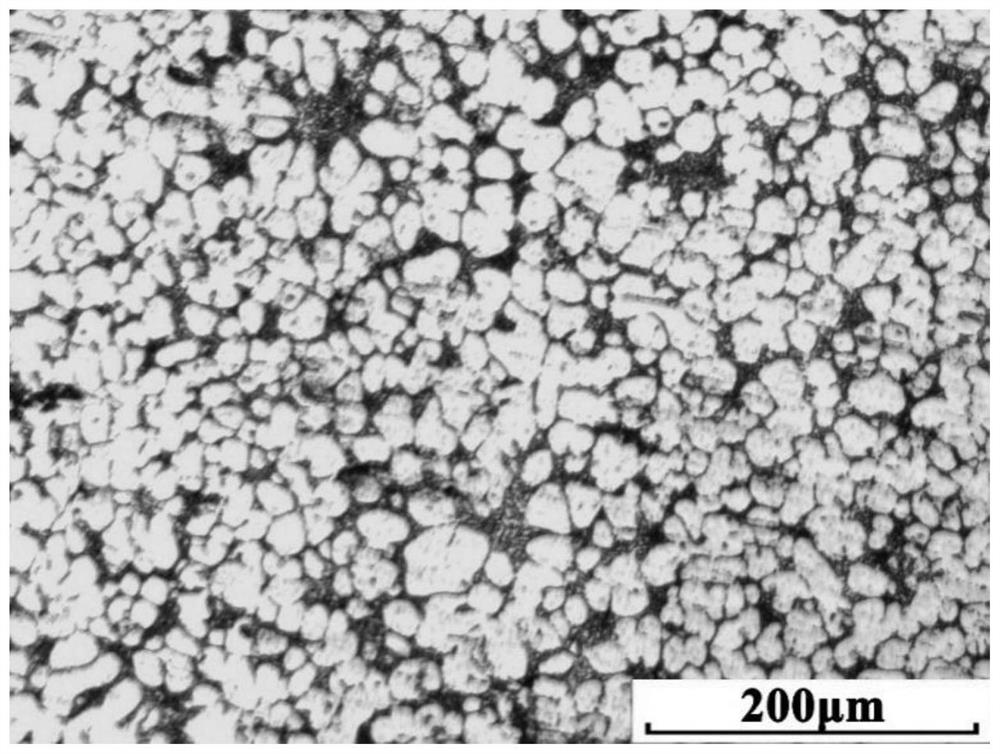

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a high thermal conductivity aluminum alloy material for semi-solid rheological die-casting, comprising the following steps:

[0033] 1) Preheating aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Sr alloy, Al-10Ce alloy and Al-10Y alloy;

[0034] 2) Heating and melting: melting the preheated aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Ce alloy and Al-10Y alloy to obtain a melt;

[0035] 3) Refining and modification: adding Al-10Sr alloy to the melt for modification treatment, and then passing argon gas into the melt for refining and degassing;

[0036] 4) Casting and solution heat treatment: the melt in step 3) is cast into shape, and then the casting is sequentially subjected to solution heat treatment and cooled with the furnace to obtain a high thermal conductivity aluminum alloy material.

[0037] In the present invention, in step 1), the raw material is preheated to 150-200°C, preferably ...

Embodiment 1

[0047] A high thermal conductivity aluminum alloy material for semi-solid rheological die-casting, the aluminum alloy material includes the following components by weight percentage: Si: 7.5%, Fe: 0.3%, Ti: 0.1%, B: 0.02%, Sr : 0.02%, rare earth elements: 0.5%, Mg<0.1%, total content of impurity elements ≤0.15%, and the rest is Al.

[0048] Its preparation method is as follows:

[0049] Aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Sr alloy, Al-10Ce alloy and Al-10Y with a mass ratio of 60:37.5:3:2:0.2:3:2 The alloy is preheated to 150°C;

[0050] Add the preheated aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Ce alloy and Al-10Y alloy into the melting furnace and melt them all to obtain a melt with a melting temperature of 750°C;

[0051] When the melt temperature drops to 720°C, add Al-10Sr alloy for modification treatment, and stir evenly; then pass argon gas into the melt for refining and degassing in the furnace. slag;

[0052] When the...

Embodiment 2

[0055] A high thermal conductivity aluminum alloy material for semi-solid rheological die-casting, the aluminum alloy material includes the following components by weight percentage: Si: 8.0%, Fe: 0.35%, Ti: 0.07%, B: 0.014%, Sr : 0.04%, rare earth elements: 0.3%, Mg<0.1%, total content of impurity elements ≤0.15%, and the rest is Al.

[0056] Its preparation method is as follows:

[0057] Aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Sr alloy, Al-10Ce alloy and Al-10Y with a mass ratio of 60.5:40:3.5:1.4:0.4:1.8:1.2 The alloy is preheated to 180°C;

[0058] Add the preheated aluminum, Al-20Si alloy, Al-10Fe alloy, Al-5Ti-1B alloy, Al-10Ce alloy and Al-10Y alloy into the furnace and melt them all to obtain a melt with a melting temperature of 755°C;

[0059] When the melt temperature drops to 725°C, add Al-10Sr alloy for modification treatment, and stir evenly; then pass argon gas into the melt for refining and degassing in the furnace. slag;

[0060] When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com