Full-data measurement path planning method foraero-engine blade

An aero-engine and measurement path technology, applied in mechanical measurement devices, measurement devices, and mechanical devices, etc., can solve the problems of high engine failure rate, affecting the working performance and service life of the whole machine, and reduce the number of measurements and redundancy. The effect of remaining data volume and rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

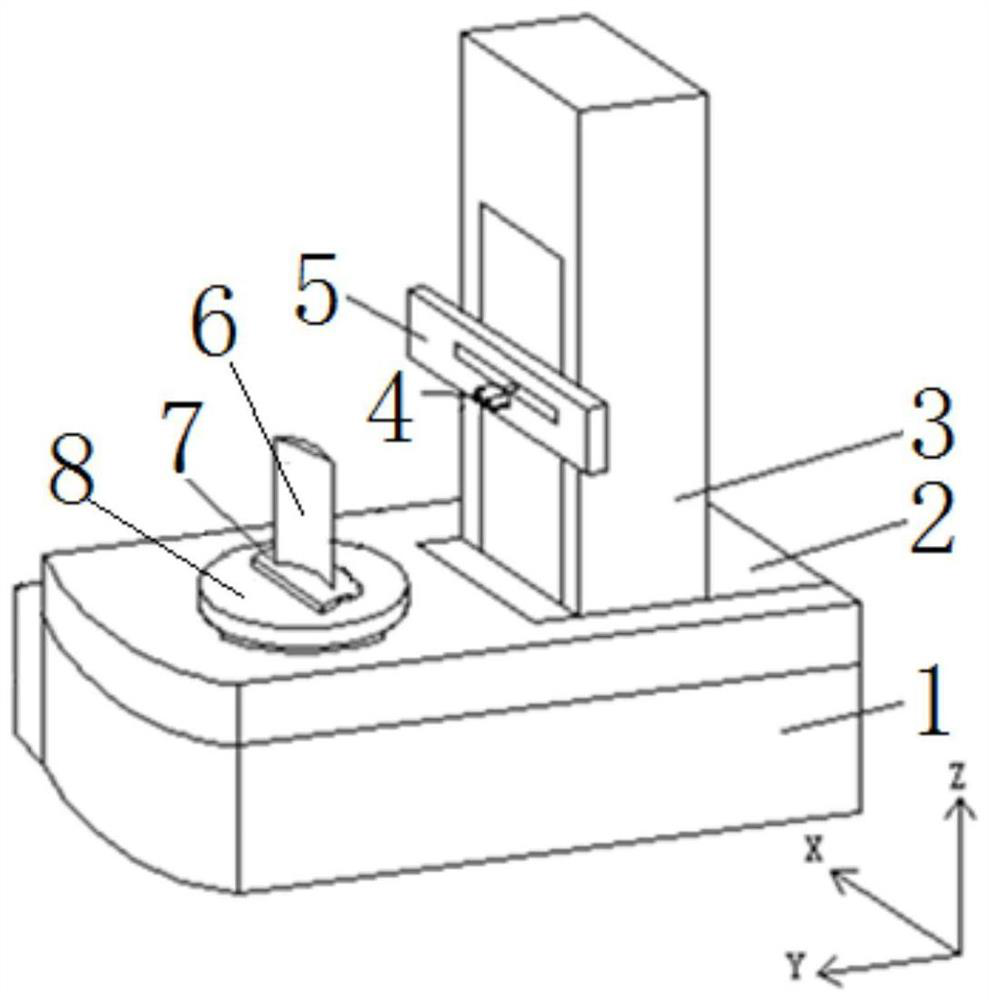

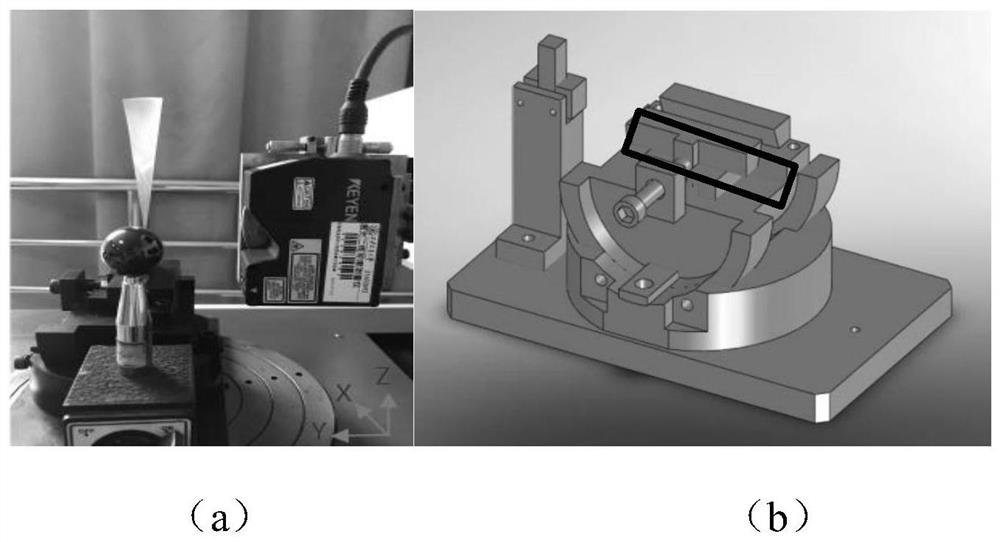

[0064] (1) Determine the sensor clamping method

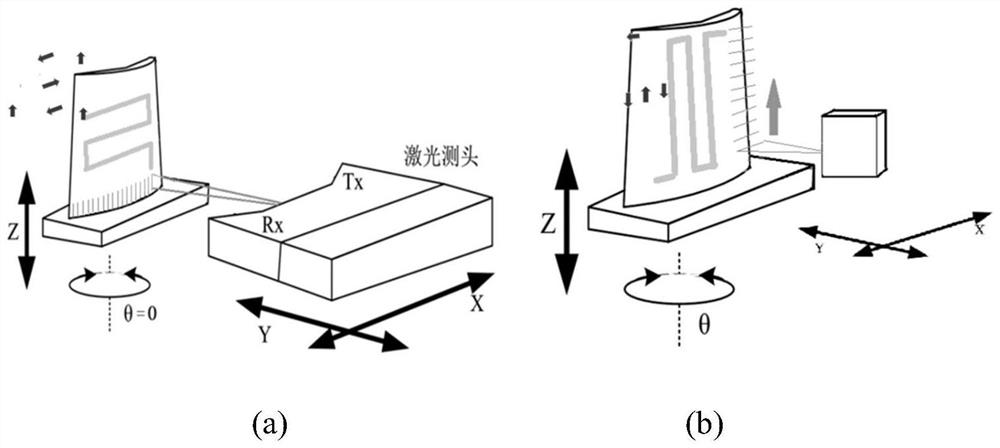

[0065] Respectively, the beam direction is parallel to the Z axis (such as figure 2 a) and the beam direction is perpendicular to the Z axis (as figure 2 Shown in b) The blade profile data is collected under two clamping methods. Taking the four-stage blade of a certain type of aero-engine compressor as a measurement example, the obtained measurement results are as follows Image 6 shown. Through the analysis of the collected data, the figure 2 The original data measured by method a have less data on the leading and trailing edges of the blade and the edges are not neat enough, which is not conducive to the subsequent point cloud data processing. Depend on figure 2 The point cloud data obtained by method b obtains a large number of data points on the front and rear edges of the blade, and has relatively neat boundary information, which can obtain better data processing effects.

[0066] (2) Path planning for blade pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com