An engineering mold heat insulation board with good pressure resistance and heat resistance performance

A heat shield and performance technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of unsatisfactory heat insulation effect of heat shield, poor pressure bearing capacity of heat shield, poor heat resistance of heat shield, etc., to achieve Long service life, improve pressure bearing capacity, reduce the effect of hot hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the heat insulation board body is as follows:

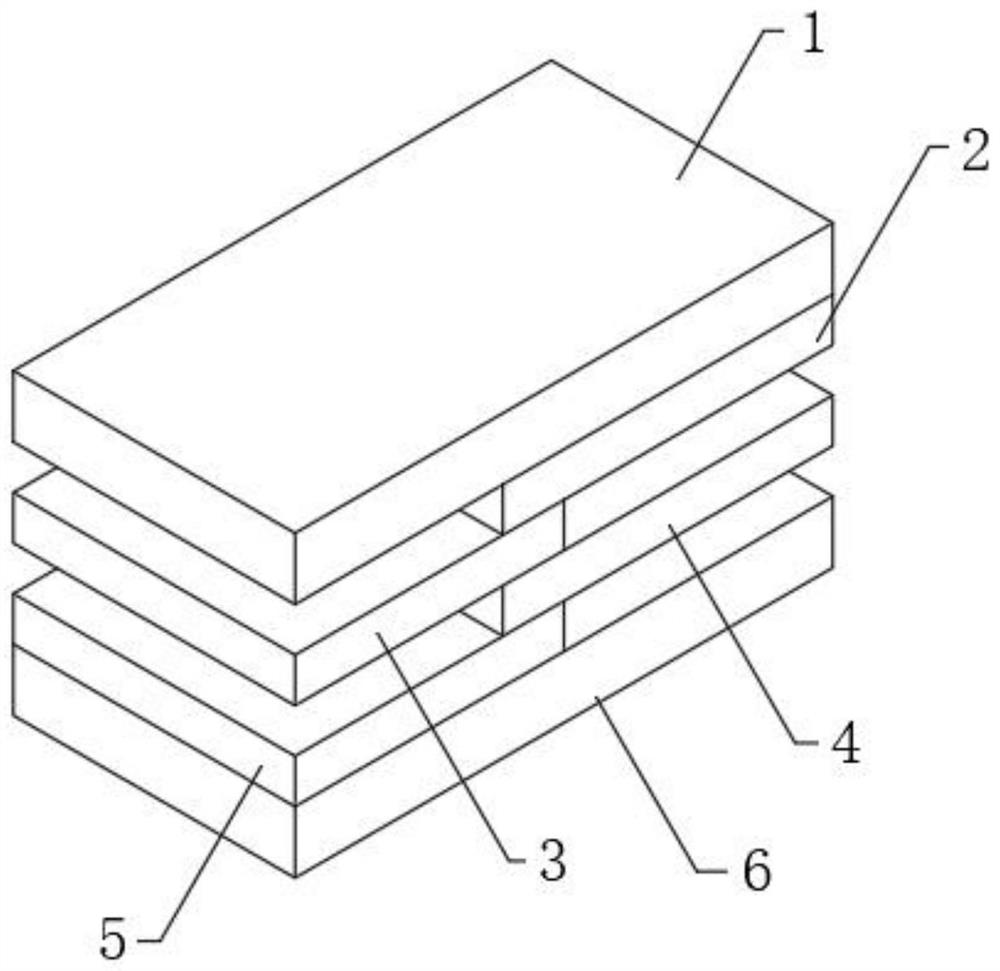

[0034] S1: The thermal insulation upper board 1 and the thermal insulation lower board 6 are made of carbon fiber and new thermal insulation reinforced materials. The high heat-resistance material is composited to make the glass fiber board 18, and then the glass fiber board 18 and the high temperature resistant synthetic stone board 17 are pressed into the first intermediate plate 2, the second intermediate plate 3, the third intermediate plate 4 and the fourth intermediate plate 5 , and through holes are opened on the surfaces of the first intermediate plate 2 , the second intermediate plate 3 , the third intermediate plate 4 and the fourth intermediate plate 5 .

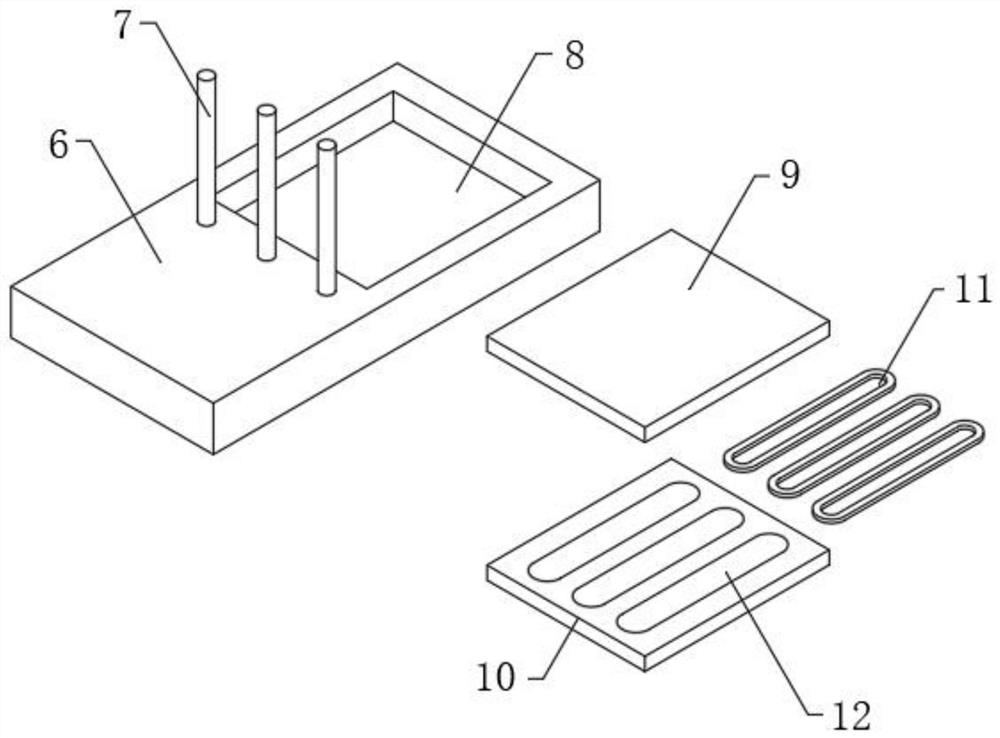

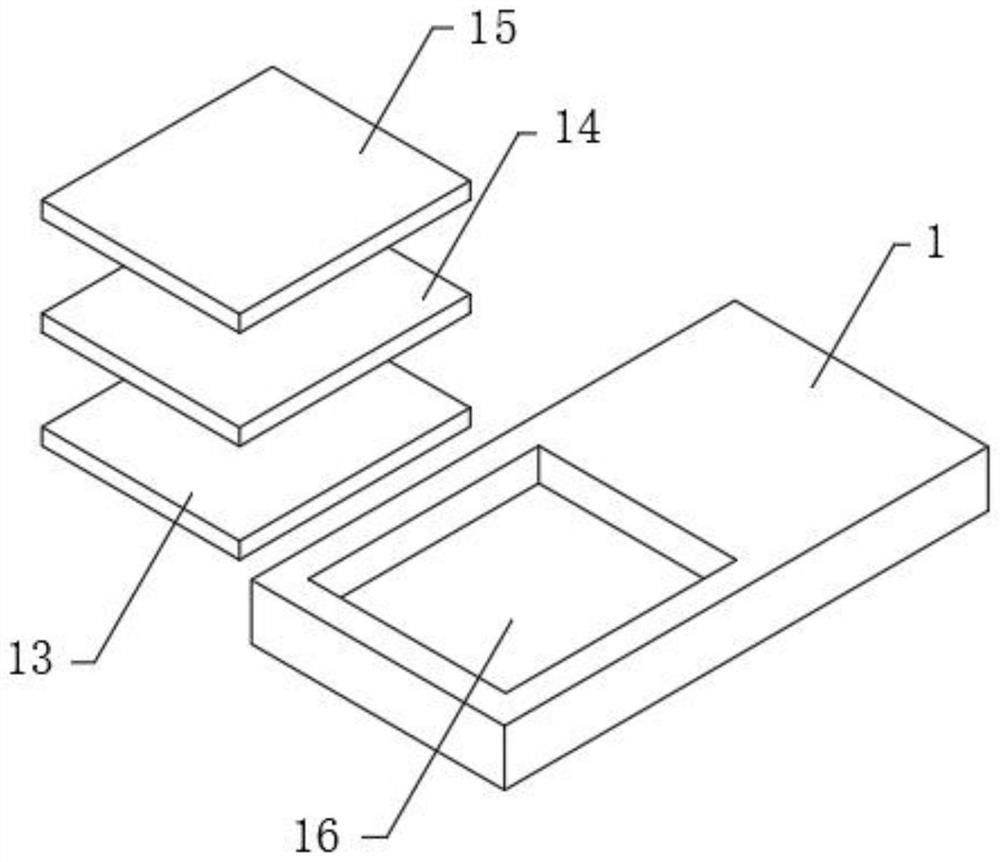

[0035]S2: The surfaces of the heat insulating upper plate 1 and the heat insulating lower plate 6 are respectively provided with an upper groove 16 and a lower groove 8, and the ultra-fine glass wool class 13, the high-silica wool boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com