Additive for reducing viscosity of lithium-sulfur battery electrolyte and synthesis method of additive

A lithium-sulfur battery and synthesis method technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high rate performance, poor thermal stability, easy flatulence, etc., to reduce conductivity, improve electrical performance, and improve rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

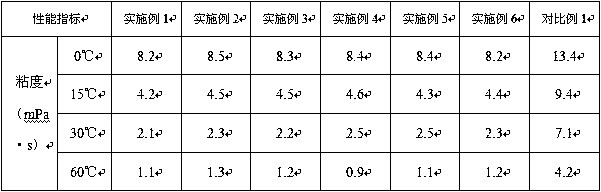

Examples

Embodiment 1

[0029] (1) Slowly add N,N'-carbonyldiimidazole into the ethyl chloride solution while stirring, and then heat the reaction in a closed environment. After the reaction is complete, carry out distillation and crystallization, so that the ethyl group is grafted on the nitrogen atom of imidazole On the above, form ethyl grafted N'N-carbonyldiimidazole chloride salt crystal particles with chlorine atoms; the stirring speed is 130r / min, and the time is 28min; the reaction temperature is 76°C, and the time is 17h;

[0030] Among them: 29 parts by weight of N,N'-carbonyldiimidazole, 71 parts by weight of ethyl chloride solution;

[0031] (2) Wash the chlorine salt crystal particles prepared in step (1) with ethyl acetate to remove residual solvent, then mix them with sodium dicyanamide powder in acetone solution, and carry out magnetic stirring under sealed conditions, and then place in Evaporation and crystallization were carried out in an unsealed environment to remove crystal parti...

Embodiment 2

[0038] (1) Slowly add N,N'-carbonyldiimidazole into the ethyl chloride solution while stirring, and then heat the reaction in a closed environment. After the reaction is complete, carry out distillation and crystallization, so that the ethyl group is grafted on the nitrogen atom of imidazole On the above, form ethyl-grafted N'N-carbonyldiimidazole chloride salt crystal particles with chlorine atoms; the stirring speed is 110r / min, and the time is 35min; the reaction temperature is 72°C, and the time is 19h;

[0039] Wherein: 25 parts by weight of N,N'-carbonyldiimidazole, 75 parts by weight of ethyl chloride solution;

[0040] (2) Wash the chlorine salt crystal particles prepared in step (1) with ethyl acetate to remove residual solvent, then mix them with sodium dicyanamide powder in acetone solution, and carry out magnetic stirring under sealed conditions, and then place in Evaporation and crystallization were carried out in an unsealed environment to remove crystal particle...

Embodiment 3

[0047] (1) Slowly add N,N'-carbonyldiimidazole into the ethyl chloride solution while stirring, and then heat the reaction in a closed environment. After the reaction is complete, carry out distillation and crystallization, so that the ethyl group is grafted on the nitrogen atom of imidazole On, form ethyl grafted N'N-carbonyldiimidazole chloride salt crystal particles with chlorine atoms; the stirring speed is 150r / min, and the time is 20min; the reaction temperature is 70°C, and the time is 20h;

[0048] Among them: 20 parts by weight of N,N'-carbonyldiimidazole, 80 parts by weight of ethyl chloride solution;

[0049] (2) Wash the chlorine salt crystal particles prepared in step (1) with ethyl acetate to remove residual solvent, then mix them with sodium dicyanamide powder in acetone solution, and carry out magnetic stirring under sealed conditions, and then place in Evaporation and crystallization were carried out in an unsealed environment to remove crystal particles, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com