A kind of thermal interface material and preparation method thereof

A thermal interface material, one-sided technology, applied in heat exchange materials, chemical instruments and methods, semiconductor devices, etc., can solve the large difference in thermal deformation between organic matter and thermally conductive particles, the decrease in thermal conductivity of composite materials, and the small thermal expansion coefficient of thermally conductive particles. and other problems to achieve the effect of avoiding the decrease of heat conduction capacity, small difference in thermal deformation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

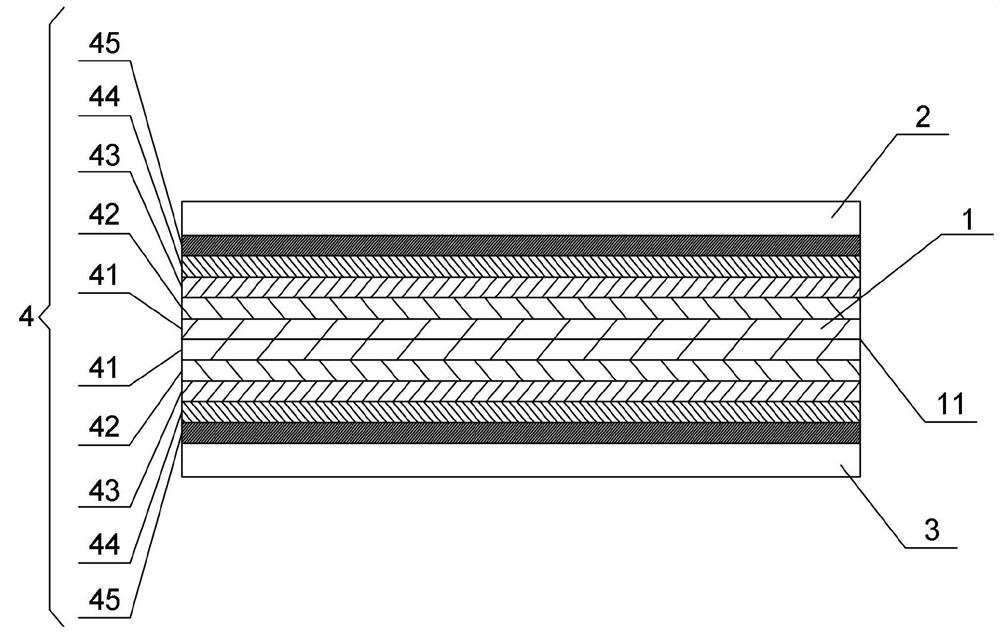

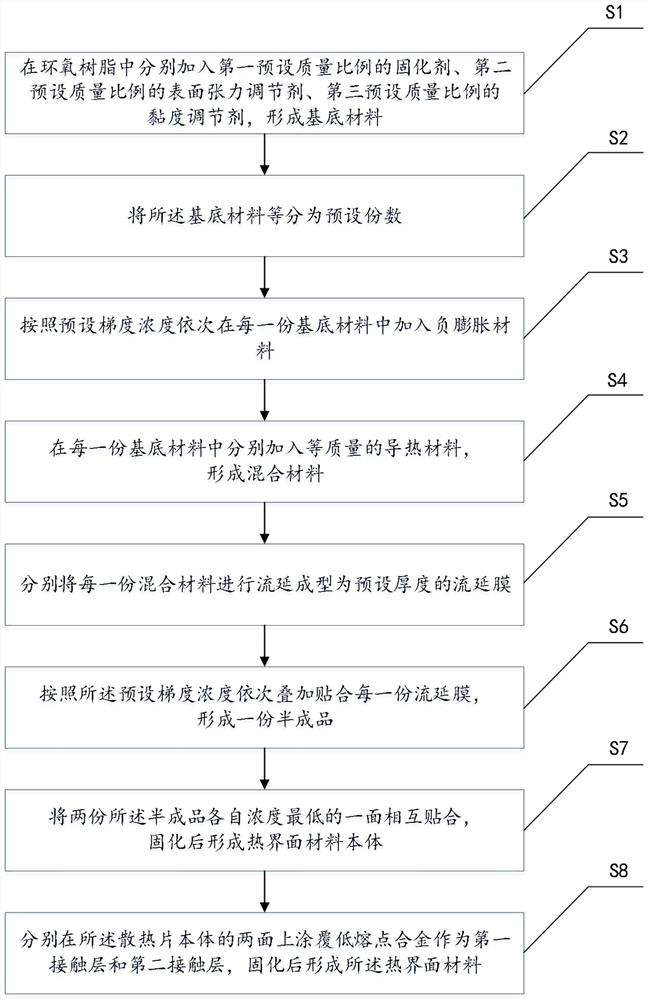

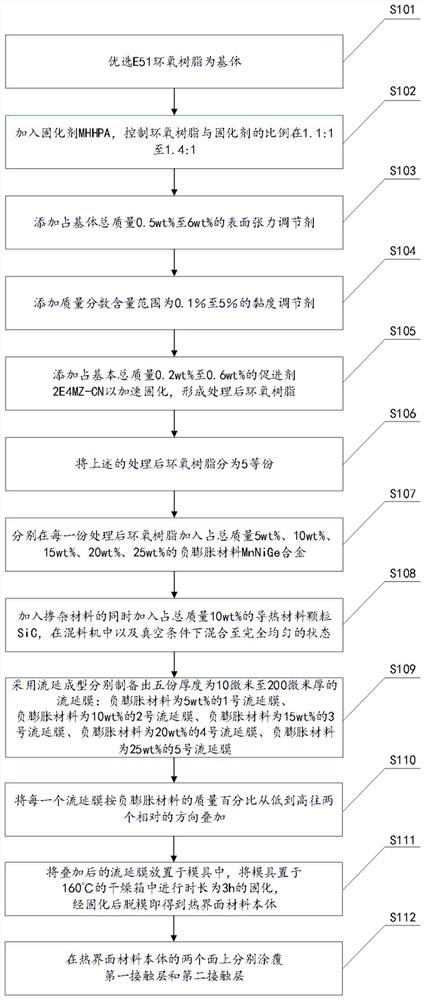

[0032] figure 1 An embodiment of the thermal interface material of the present invention for a heat sink is shown, see figure 1 , in this embodiment, the thermal interface material includes a base material layer 1 , a first contact layer 2 , a second contact layer 3 and a doping material 4 .

[0033] Wherein, the base material layer 1 is made of a material with a positive thermal expansion coefficient or a material with a negative thermal expansion coefficient, and the first contact layer 2 covers one side of the base material layer 1 and is in contact with a heat source; the second contact layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com