Cyclic pre-deformation method for improving creep age forming capacity and performance of aluminum alloy

A technology of creep aging forming and pre-deformation, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., to achieve the effects of improving formability, saving energy consumption, improving forming accuracy and manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

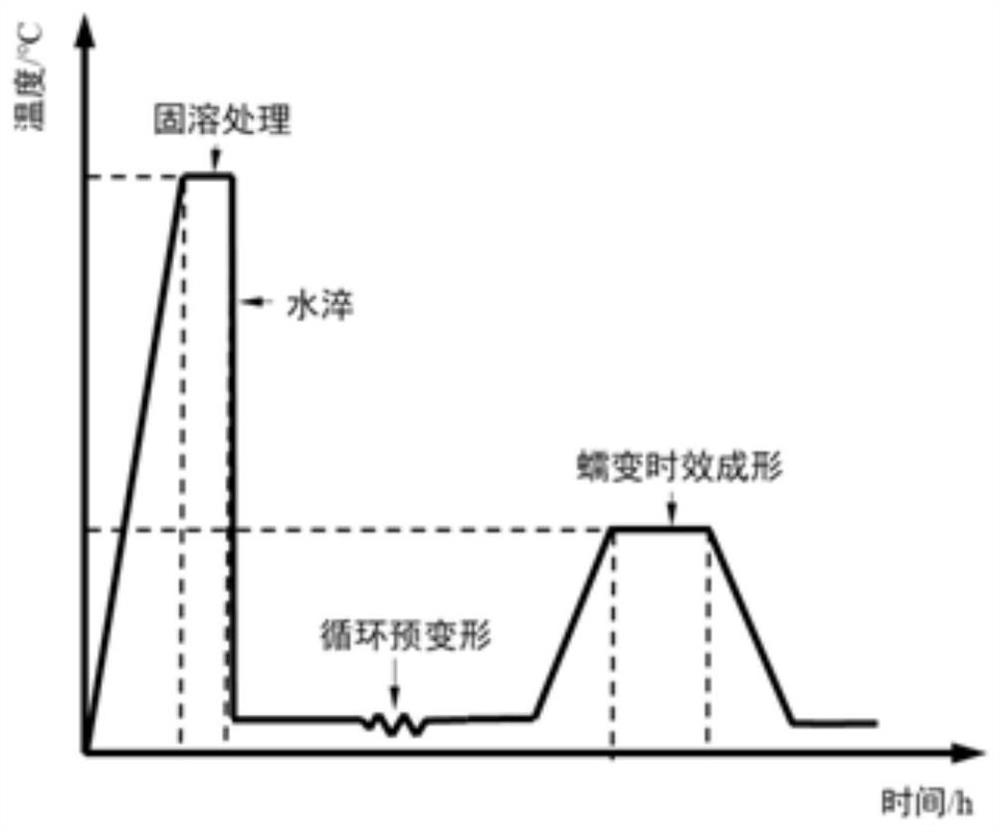

Method used

Image

Examples

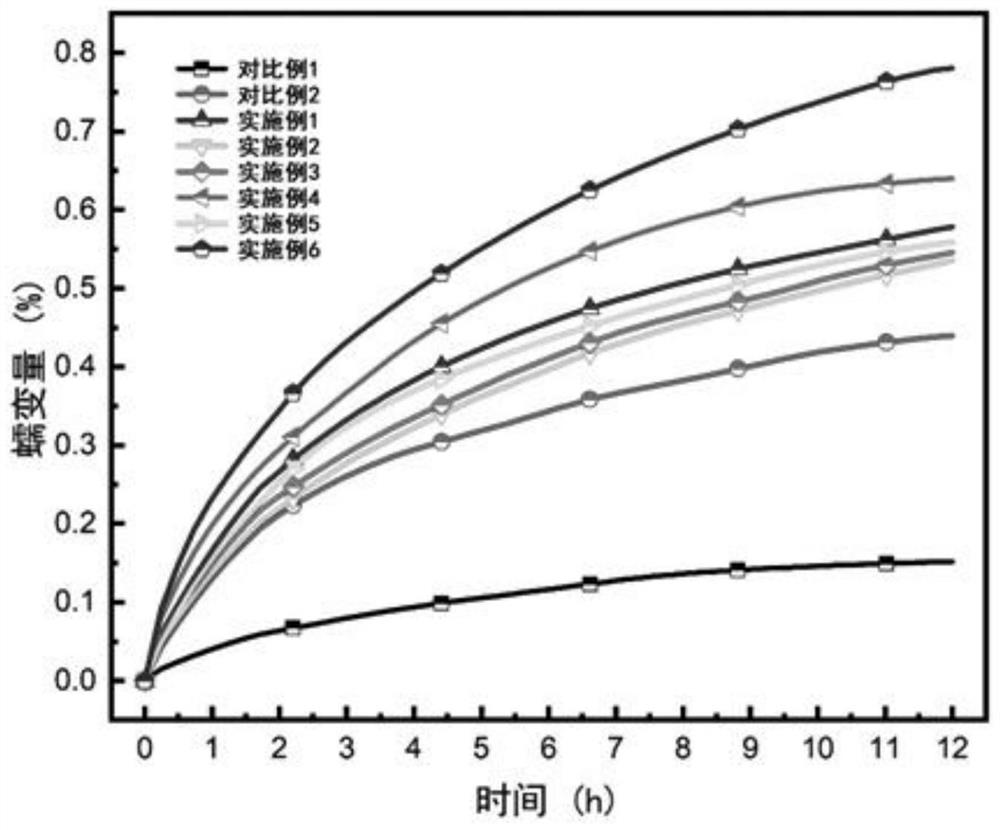

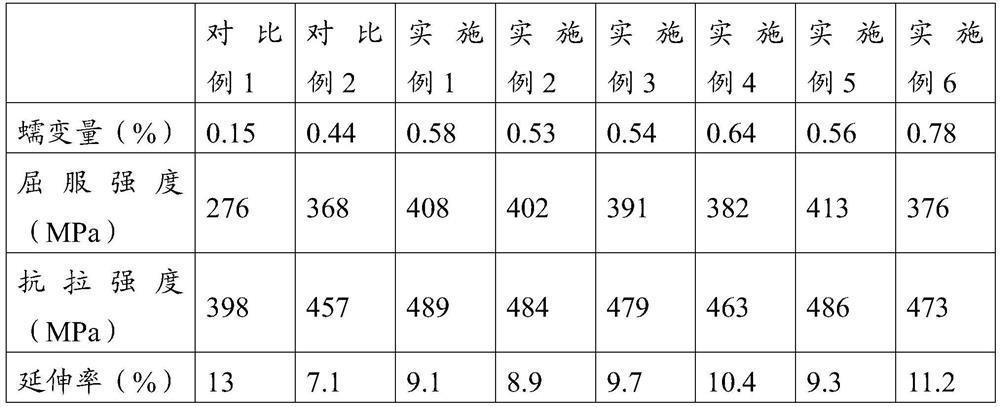

Embodiment 1

[0031] The 2219 aluminum alloy is subjected to solution treatment at 535°C for 1 hour in an air circulation resistance furnace, and after water quenching, an aluminum alloy plate is obtained. Then the plate is subjected to cyclic pre-deformation treatment, the cyclic strain amplitude is 0.5%, the strain ratio is -1 (tension-compression symmetry), the frequency is 0.5Hz, the number of cycles is 500 times, and the cycle test temperature is kept at room temperature 25°C. After that, creep aging treatment is carried out. The creep aging temperature is 165°C, the creep time is 12h, and the creep stress is 150MPa. The tensile test is carried out after the plate is taken out and cooled at room temperature.

Embodiment 2

[0033] The 2219 aluminum alloy is subjected to solution treatment at 535°C for 1 hour in an air circulation resistance furnace, and after water quenching, an aluminum alloy plate is obtained. Then the plate is subjected to cyclic pre-deformation treatment, the cyclic strain amplitude is 0.5%, the strain ratio is -1 (tension-compression symmetry), the frequency is 0.5Hz, the number of cycles is 500 times, and the cycle test temperature is kept at room temperature 25°C. Afterwards, creep aging treatment is carried out. The creep aging temperature is 165°C, the creep time is 12h, and the creep stress is 50MPa. The tensile test is carried out after the plate is taken out and cooled at room temperature.

Embodiment 3

[0035] The 2219 aluminum alloy is subjected to solution treatment at 535°C for 1 hour in an air circulation resistance furnace, and after water quenching, an aluminum alloy plate is obtained. Then the plate is subjected to cyclic pre-deformation treatment, the cyclic strain amplitude is 0.5%, the strain ratio is -1 (tension-compression symmetry), the frequency is 0.5Hz, the number of cycles is 500 times, and the cycle test temperature is kept at room temperature 25°C. After that, creep aging treatment is carried out. The creep aging temperature is 120°C, the creep time is 12h, and the creep stress is 150MPa. The tensile test is carried out after the plate is taken out and cooled at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com