Tail gas burner

A burner and tail gas technology, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of unable to organize tail gas, unable to eliminate flameout, tempering, etc., to avoid local high temperature burning parts, reduce emissions, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In order to solve the technical problems existing in the prior art, an embodiment of the present invention provides an exhaust gas burner.

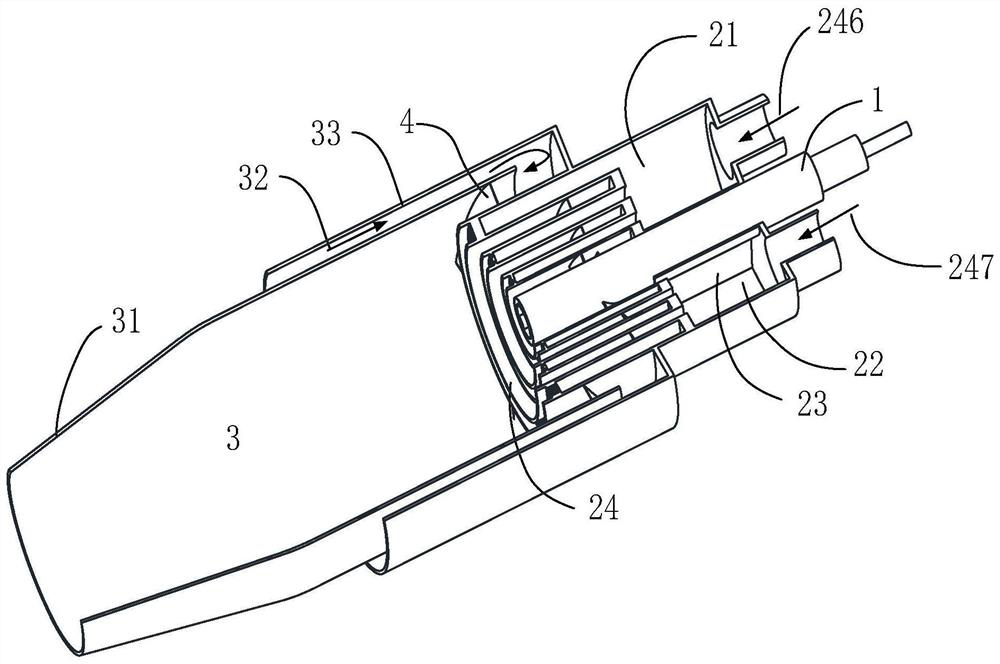

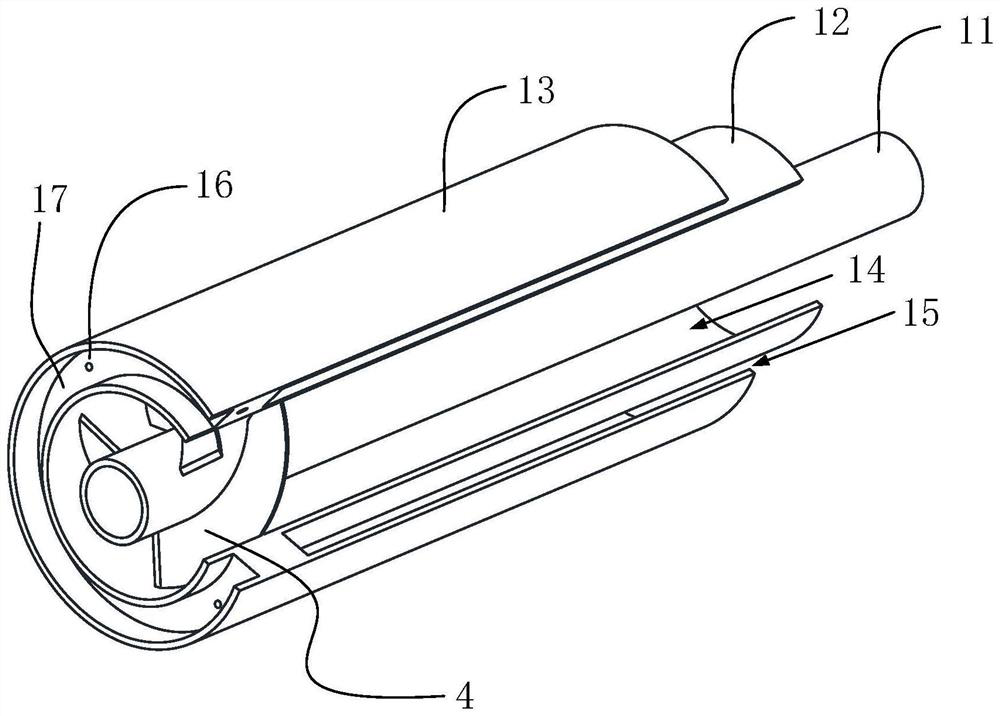

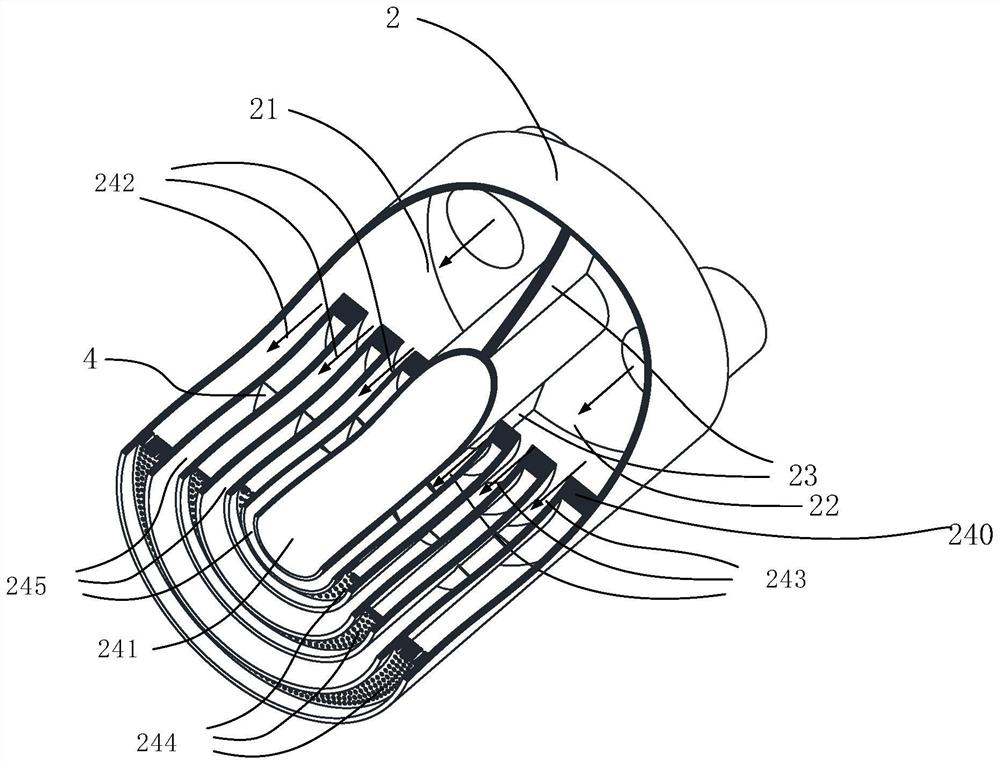

[0029] figure 1 An overall sectional view of an exhaust gas burner in an embodiment of the present invention is shown; refer to figure 1 As shown, the exhaust gas burner of the embodiment of the present invention includes a duty flame nozzle 1, an exhaust gas nozzle assembly 2 and a combustion chamber 3, the exhaust gas nozzle assembly 2 is arranged on the periphery of the duty flame nozzle 1, and the combustion chamber 3 is arranged on the duty flame nozzle 1 and the exhaust gas nozzle The rear of component 2 provides a combustion space for the combustion of exhaust gas and on-duty flame. The on-duty flame nozzle 1 is used to control the degree of combustion to achieve stable combustion of the exhaust gas ejected from the exhaust nozzle. The exhaust nozzle assembly 2 is used for exhaust gas combustion and controls the anode exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com