Thermoplastic resin composition with inorganic substance powder blended therein, and molded article

A thermoplastic resin and inorganic substance technology, applied in the field of thermoplastic resin compositions and molded products, can solve the problems that the mechanical properties of the surface state of molded products cannot be improved, and uneven distribution is not considered, so as to achieve good mechanical properties and suppress The effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

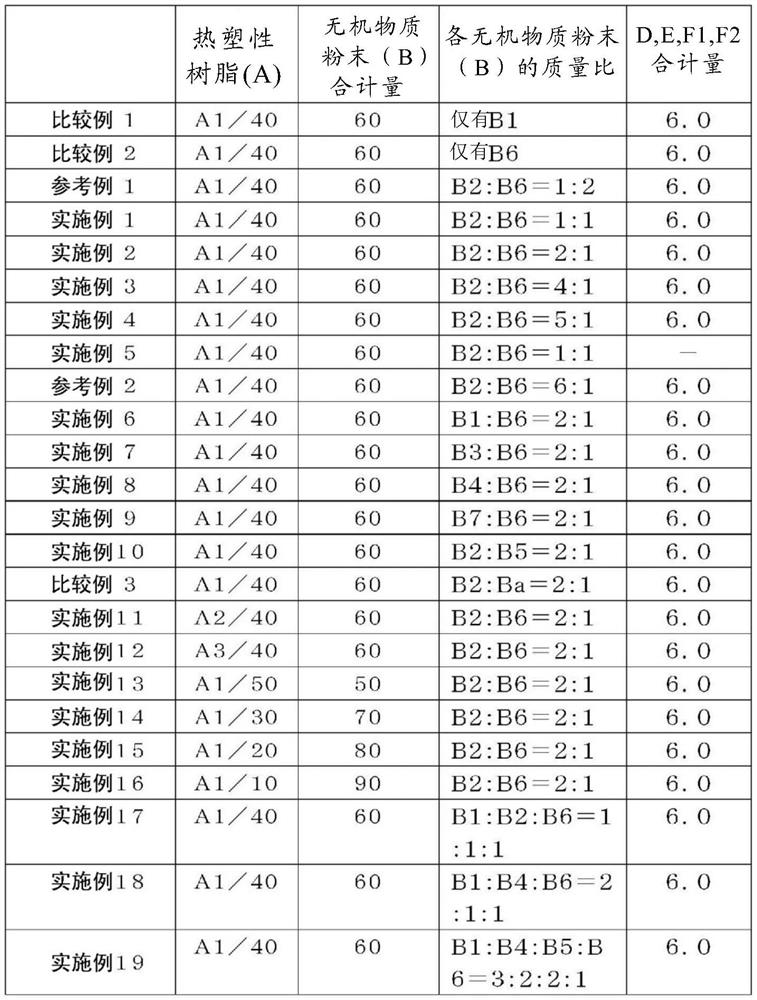

[0156] The polypropylene homopolymer A1 was used as the thermoplastic resin (A) and the above-mentioned B2 and B6 were used as the inorganic substance powder (B) at the mixing ratio shown in Table 1. As an antistatic agent, a lubricant, and an antioxidant material, the above-mentioned D, E, F1, and F2 were used in appropriate amounts, respectively, so that the total amount was 6.0 parts by mass. Except for Example 5, the mixing amounts of the antistatic agent, lubricant, and antioxidant were the same in other Examples and Comparative Examples shown below. In addition, the numerical value of each component in Table 1 is the value of mass parts. Each component was put into an extrusion molding machine equipped with a twin-screw screw (T-die extrusion molding device manufactured by Toyo Seiki Seisakusho ( L / D = 25), kneading at 200°C, extrude the kneaded raw material and 220°C (mold temperature) from a T-die into a sheet, and use Toyo Seiki's film / sheet recycling machine to tak...

Embodiment 2~10、 comparative example 1~6

[0159] The types and contents of each component in the thermoplastic resin composition were changed in the same manner as in Example 1 except that the types and contents of each component in the thermoplastic resin composition were changed according to the following Table 1. Sheets with a wall thickness of 200 μm were produced and their properties were evaluated. The obtained results are shown in Table 2.

[0160] 【Table 1】

[0161]

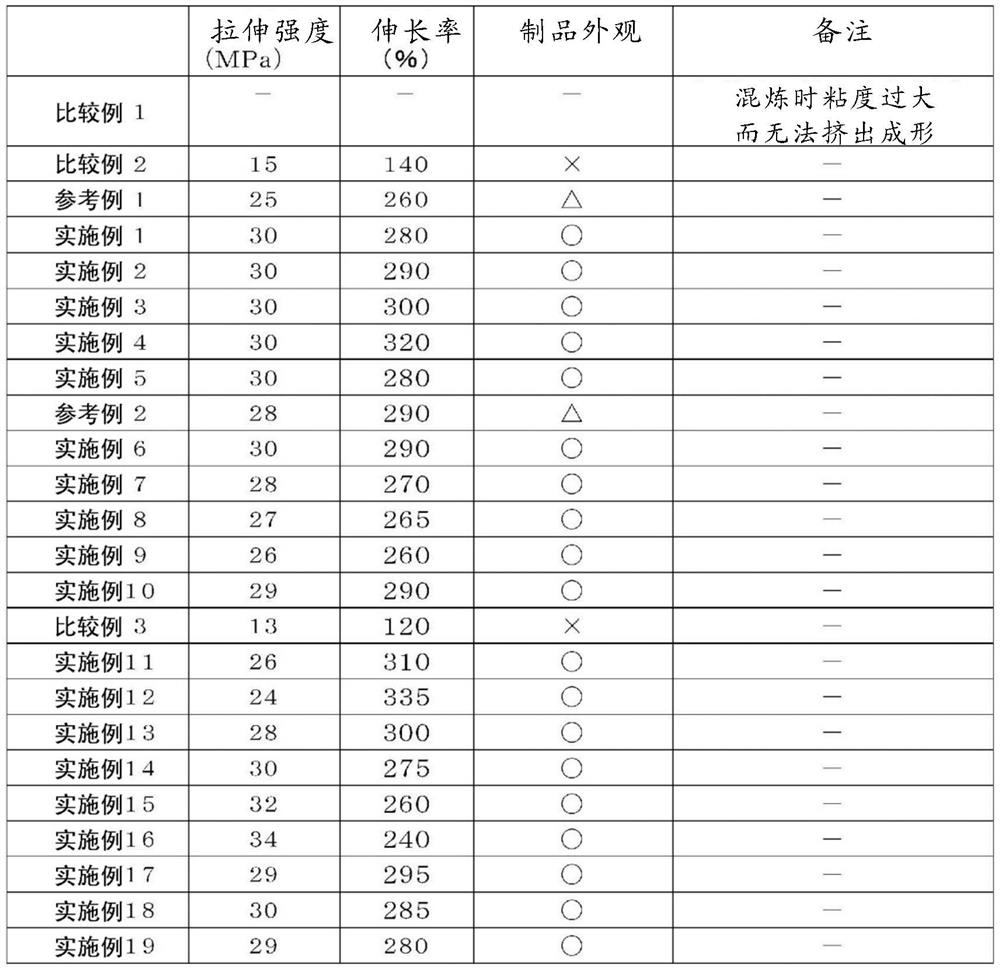

[0162] 【Table 2】

[0163]

[0164] According to the results in Table 2, in the examples of the present invention, when the mixing amount of the inorganic substance powder is high, the inorganic substance powder can be uniformly added to the resin component to avoid uneven distribution, and extrusion can be performed normally and stably. After molding, the obtained molded product has an excellent appearance and a molded product with good mechanical properties can also be obtained.

Embodiment 20

[0166] The thermoplastic resin composition containing the inorganic substance powder having the same composition as in Example 1 was formed into a sheet using a twin-screw extruder at a temperature of 220° C. using a T-die, and then further formed into a deep disc shape at a temperature of 220° C. Vacuum forming of container bodies. As a result, similar to the case of the above-mentioned Example 1, it is possible to manufacture a container body having sufficient mechanical properties and having a good appearance while avoiding occurrence of defects during processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com