Sizing method of polylactic acid fiber yarn

A technology of polylactic acid fiber and sizing method, which is applied in fiber type, fiber treatment, textiles and papermaking, etc. It can solve the problems of polylactic acid fiber yarn quality deterioration and poor degradability of sizing, and reduce the amount of chemicals used , Avoid the effects of poor quality and low sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

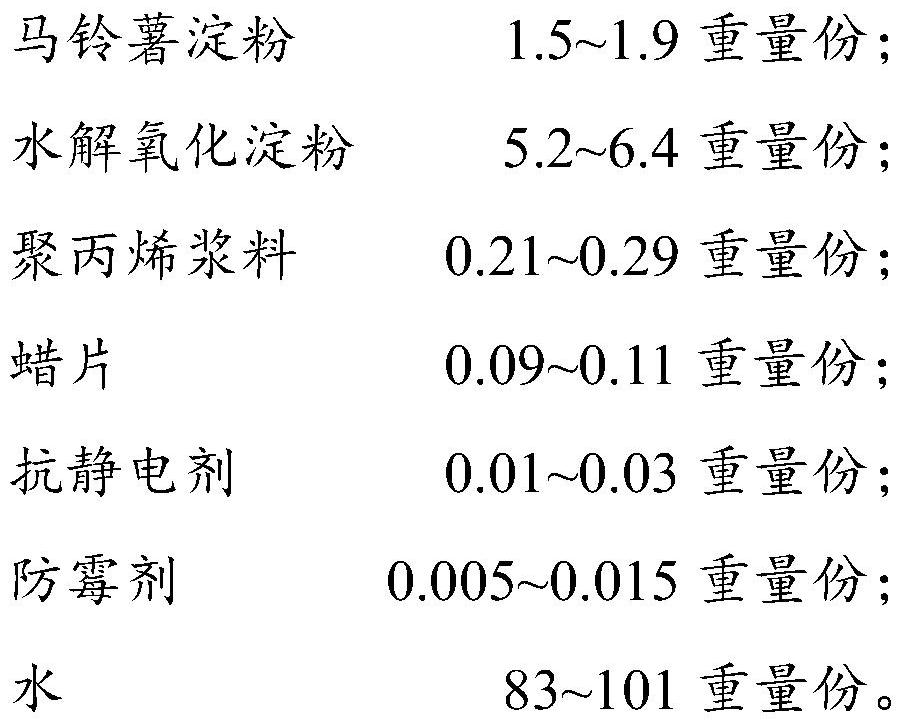

Embodiment 1

[0040] According to the slurry formula ratio of Example 1 shown in Table 1, the raw materials were weighed for subsequent use. Add 5 grids of water into the high pressure barrel (the height in the high pressure barrel is divided into 10 grids), and add the weighed potato starch, hydrolyzed oxidized starch, and polypropylene slurry into the high pressure barrel in turn under the low-speed stirring condition of 300r / min. , wax flakes, antistatic agent and antifungal agent, continue to stir at a low speed of 300r / min for 7.5min, then add the remaining water, close the high-pressure barrel and carry out high-speed stirring at 600r / min, when the steam pressure is below 1.5MPa and the temperature in the barrel Under the condition of 100°C-110°C, boil the pulp for 17.5 minutes and then transfer it to the slurry supply tank. Under the condition of stirring at a low speed of 300r / min, adjust the solid content, temperature and viscosity of the slurry so that the solid content of the prep...

Embodiment 2

[0049] According to the slurry formula ratio of Example 2 shown in Table 1, the raw materials were weighed for subsequent use. Add water at a height of 5 grids to the high-pressure barrel, and add the weighed potato starch, hydrolyzed oxidized starch, polypropylene slurry, wax flakes, antistatic agent and anti-mildew Continue to stir at a low speed of 300r / min for 5.0min, then add the remaining water, close the high-pressure barrel and carry out high-speed stirring at 600r / min, boil the pulp under the conditions of steam pressure below 1.5MPa and temperature in the barrel of 100°C to 110°C After 15.0 minutes, it was transferred to the slurry supply tank, and the solid content, temperature and viscosity of the slurry were adjusted under the low-speed stirring condition of 300r / min, so that the solid content of the prepared slurry was 6.5%, the temperature was 65°C, and the viscosity was 5.0s. The pH value is 7.0, and the slurry after slurry adjustment is obtained.

[0050] Con...

Embodiment 3

[0058] According to the slurry formula ratio of Example 3 shown in Table 1, the raw materials were weighed for subsequent use. Add water at a height of 5 grids to the high-pressure barrel, and add the weighed potato starch, hydrolyzed oxidized starch, polypropylene slurry, wax flakes, antistatic agent and anti-mildew Continue to stir at a low speed of 300r / min for 10.0min, then add the remaining water, close the high-pressure barrel and carry out high-speed stirring at 600r / min, boil the pulp under the conditions of steam pressure below 1.5MPa and temperature in the barrel of 100°C to 110°C After 20.0 minutes, it was transferred to the slurry supply tank, and the solid content, temperature and viscosity of the slurry were adjusted under the low-speed stirring condition of 300r / min, so that the solid content of the prepared slurry was 7.5%, the temperature was 75°C, and the viscosity was 6.0s. The pH value is 8.0, and the slurry after slurry adjustment is obtained.

[0059] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com