Regenerative denitration catalyst, method for producing same, and denitration device

The technology of a denitration catalyst and a manufacturing method is applied in the fields of regenerated denitration catalyst and its manufacture and denitration device, which can solve the problems such as the reduction of denitration performance, and achieve the effect of restoring denitration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

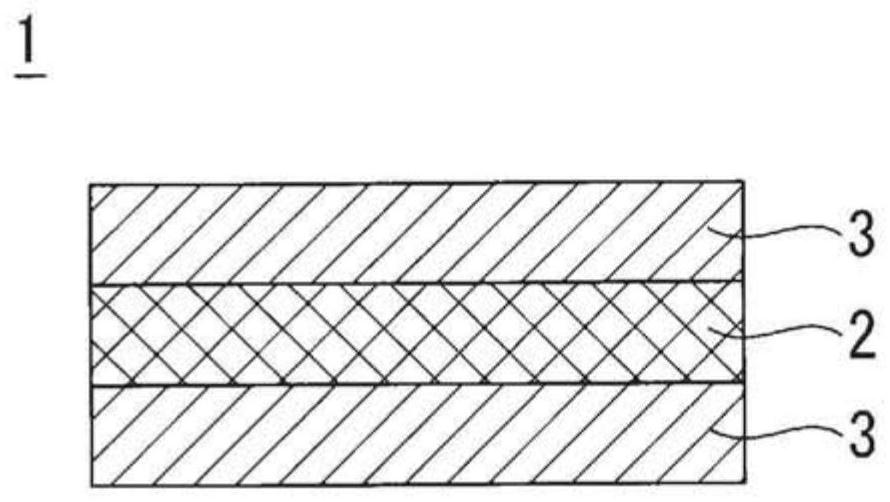

[0037] The regenerated denitration catalyst according to this embodiment includes: a used denitration catalyst mainly composed of a first titanium oxide; and a second titanium oxide. In the regenerated denitration catalyst, the first titanium oxide contained in the used denitration catalyst is mixed with the second titanium oxide. Titanium oxides (the first titanium oxide and the second titanium oxide) can be included in the range of, for example, 60% by weight to 85% by weight, preferably 70% by weight to 80% by weight, relative to the total weight of the regenerated denitration catalyst. In regenerated denitration catalyst.

[0038] The "first titanium oxide" is a used name of the titanium oxide contained in the denitration catalyst before use. "Main component" refers to the component contained most in the object. The specific surface area per unit weight of the titanium oxide contained in the denitration catalyst before use can be, for example, about 100m 2 / g. The spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com