Automatic three-dimensional breeding system and breeding method for hermetia illucens

An automatic three-dimensional, breeding system technology, applied in animal husbandry, etc., to achieve high efficiency, low breeding cost, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

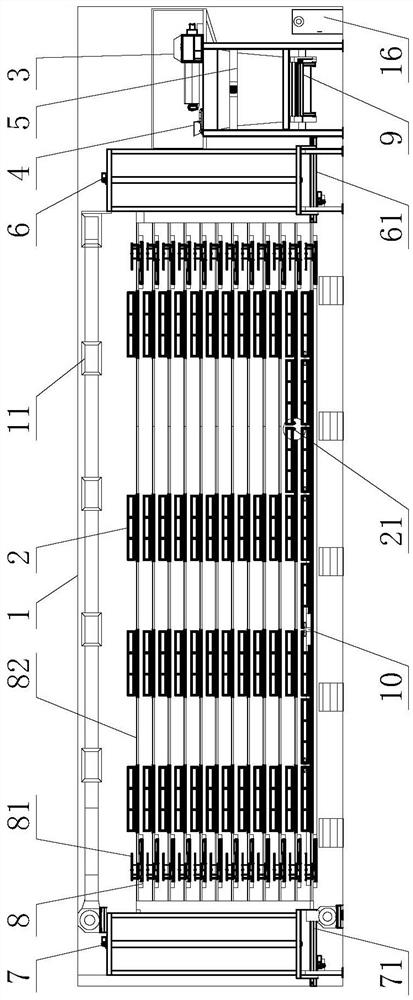

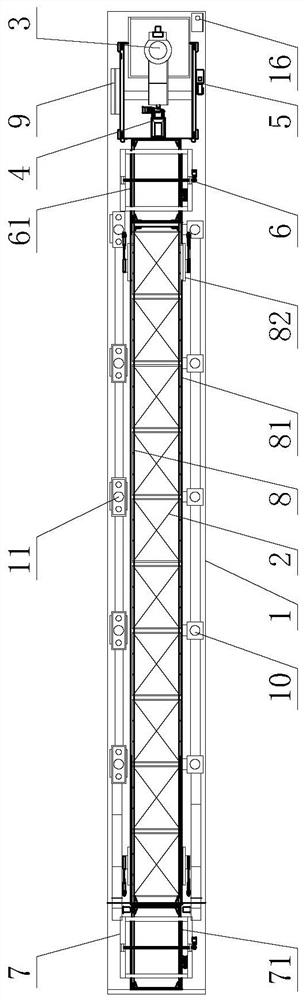

[0067] see Figure 1 to Figure 2 As shown, the black soldier fly automatic three-dimensional breeding system of Embodiment 1 of the present invention mainly consists of a frame cabinet 1, a breeding tray 2, a feed loading machine 3, a seeding device 4, a turning and unloading machine 5, a front tray elevator 6, a rear Tray lifter 7, pallet conveying device 8, screening machine 9, temperature regulating device 10, deodorizing device 11 and system controller 16; described breeding pallet 2, feed loading machine 3, seeding device 4, turning over and discharging machine 5 , the front tray lifter 6, the rear tray lifter 7, the tray delivery device 8, the screening machine 9 and the system controller 16 are installed in the frame cabinet 1; the breeding tray 2 is located on the tray delivery device 8; the feed The tray loading machine 3 and the seeding device 4 are connected and installed above the turning and unloading machine 5; the front tray lifter 6 is connected and installed b...

Embodiment 2

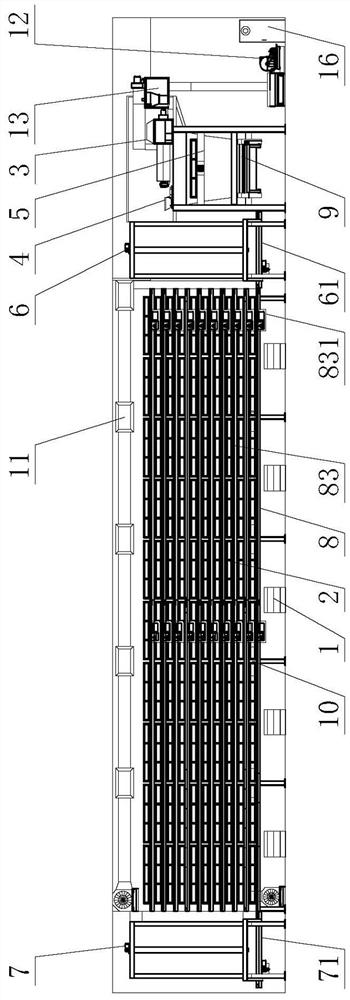

[0075] see image 3 Shown, the black soldier fly automatic three-dimensional culture system of embodiment two of the present invention is similar to embodiment one, and difference is only in:

[0076] In order to reduce the transportation space of the breeding tray 2 and save transportation costs, the breeding tray 2 is designed and processed so that the size of the mouth is 2500mm long and 1500mm wide, the bottom size of the dish is 2480mm long and 1480mm wide, and the volume is 150mm deep, which can be embedded in each other. The set of inverted trapezoidal trays is an injection molded plastic tray.

[0077] The pallet conveying device 8 is composed of the pallet conveying unit 83, the pallet conveying unit 83 is composed of the pallet chain conveyor 831, and the pallet chain conveyor 831 is connected and installed on the two inner sides of the frame cabinet 1 ; The pallet conveyor 83 is provided with ten floors in the vertical direction, and two pallet chain conveyors 831 ...

Embodiment 3

[0080] see Figure 4 Shown, the black soldier fly automatic three-dimensional breeding system of embodiment three of the present invention is similar to embodiment two, and difference only is:

[0081] In order to further improve the palatability and conversion rate of the feed, if it is necessary to add a certain proportion of raw materials with high protein content such as wheat bran, corn flour, beer dregs, etc. Fermentation, adding feed mixing equipment 14 and feed fermentation equipment 15, the feed mixing equipment 14 is connected and installed at the rear end of the feed crushing equipment 12, and is connected to the feed fermentation equipment 15 through the feed delivery equipment 13 , the beverage fermenting equipment 15 is connected with the feed packing machine 3 through the feed conveying equipment 13 .

[0082] The breeding method of the black soldier fly automatic three-dimensional breeding system of the present invention comprises the following steps:

[0083...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com