Process design and construction method of large circular structure wood pattern

A technology of process design and construction method, which is applied to the connection parts of formwork/formwork/work frame, building type, building structure, etc., can solve the problems of rapid construction of the circular pool wall with ordinary wooden formwork, and achieve easy Effects of acquisition, cost reduction, and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

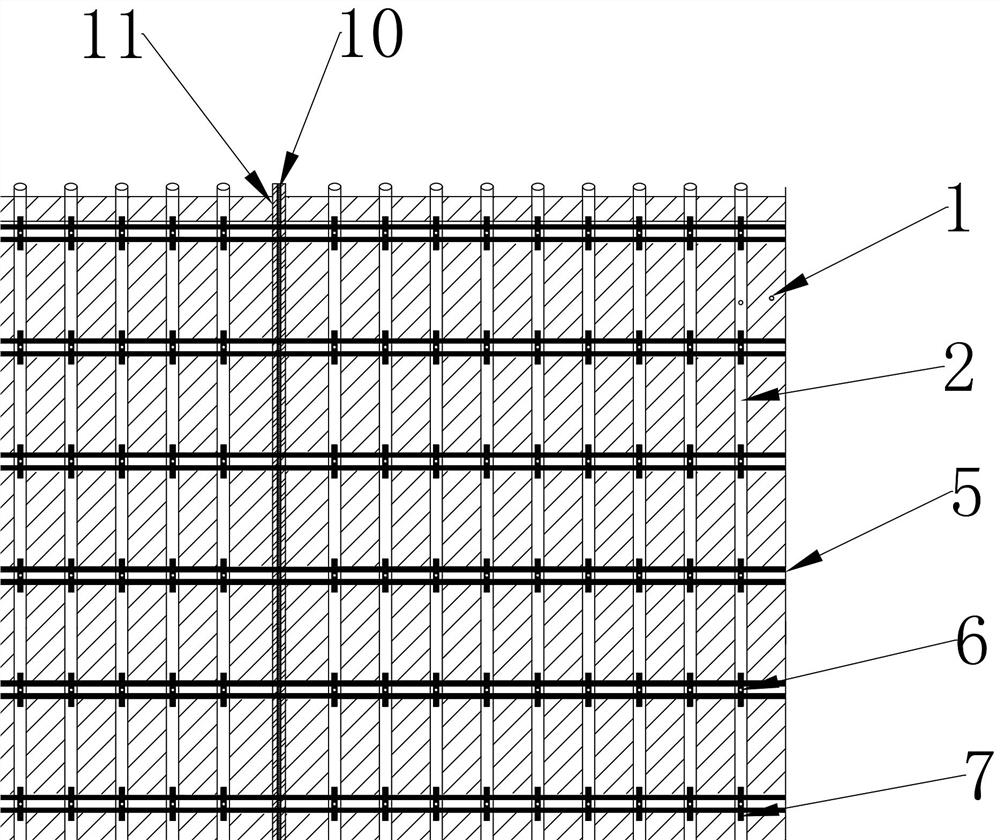

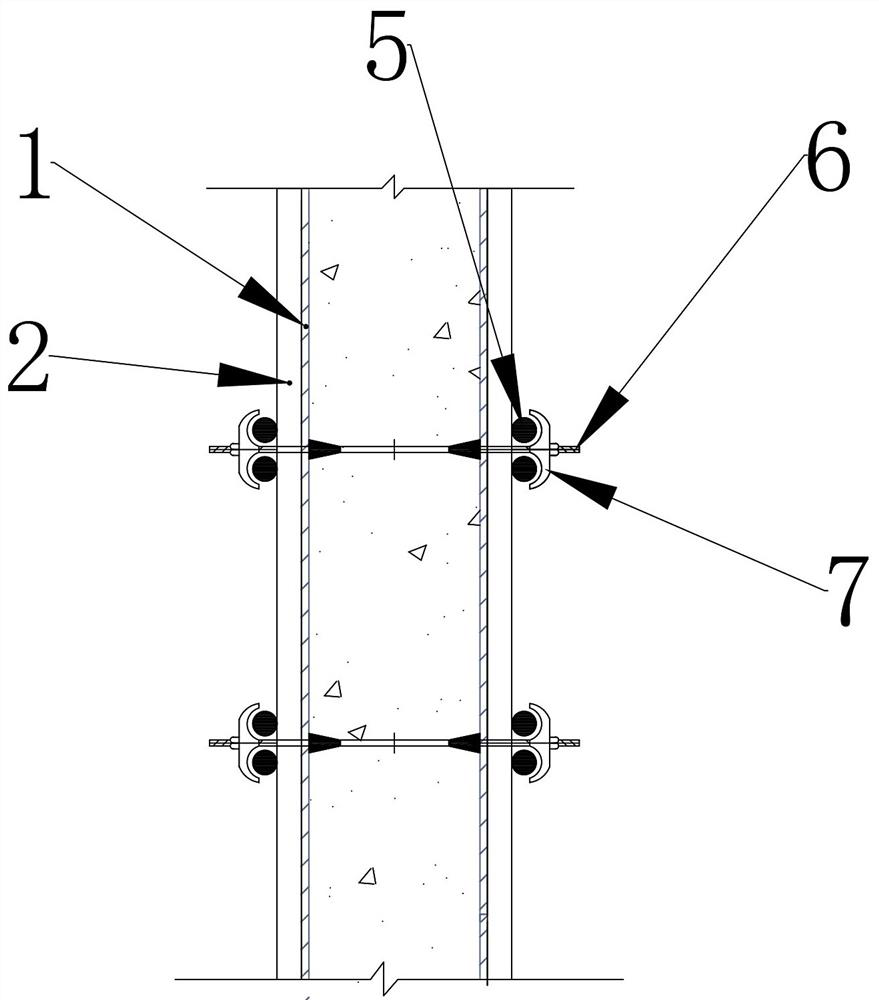

[0040] Such as Figure 1-10 Among them, a large-scale circular structure wooden formwork design and construction method, including the following steps:

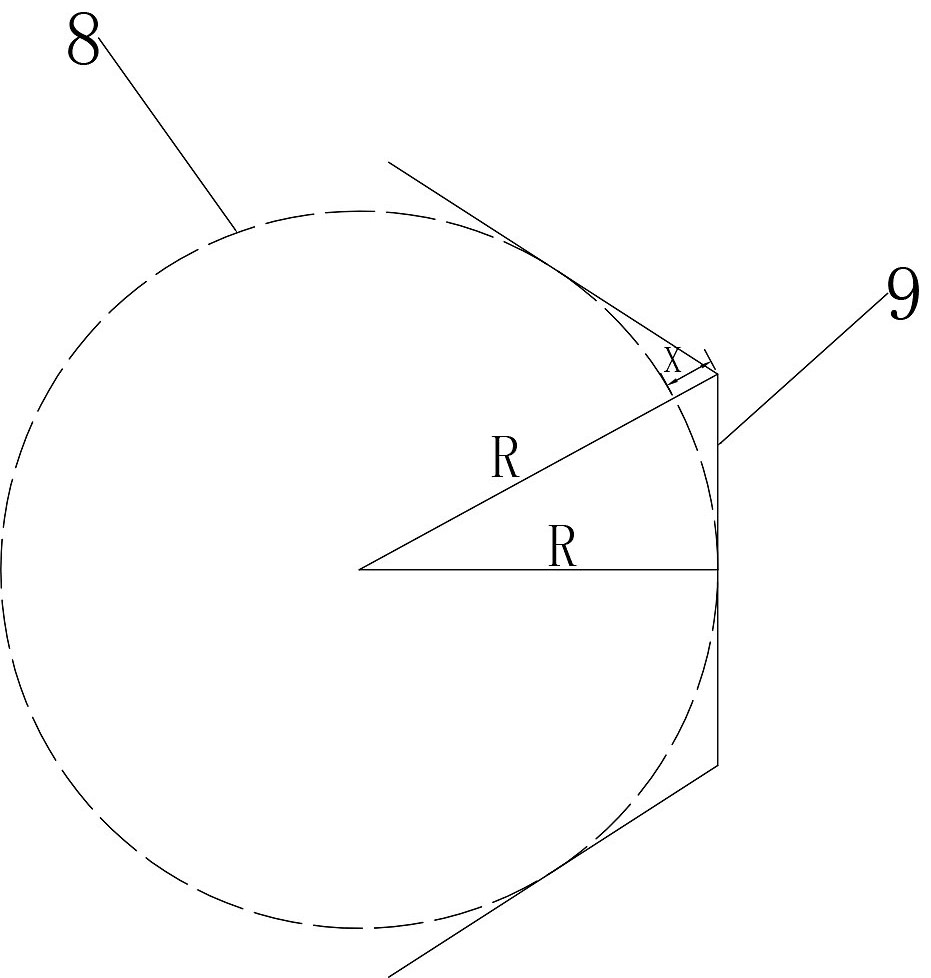

[0041] S1. According to the external dimensions of the linear 8 designed on the structure to be produced, a plurality of ordinary wooden templates 1 are used to connect, and the shape of the envelope curve with the minimum perimeter is obtained through curve fitting, thereby obtaining the fitted linear 9; considering the template Versatility and economy, using conventional wooden formwork 1 (such as 1830×915mm) to fit and assemble with straight-forward curves. Since there will inevitably be a certain deviation between the fitted line type and the designed line type, when the deviation is within the allowable range, it is considered that the line type fits well; when the deviation exceeds the range, it is necessary to make a comprehensive judgment based on the structural importance and appearance requirements use.

[0042] D...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap