Material surface fog detection method and device

A detection material and signal detection technology, which is applied in measurement devices, analysis materials, and optical devices, etc., can solve problems such as inability to detect, lack of accurate detection materials, and no reference significance, and achieve the effect of accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

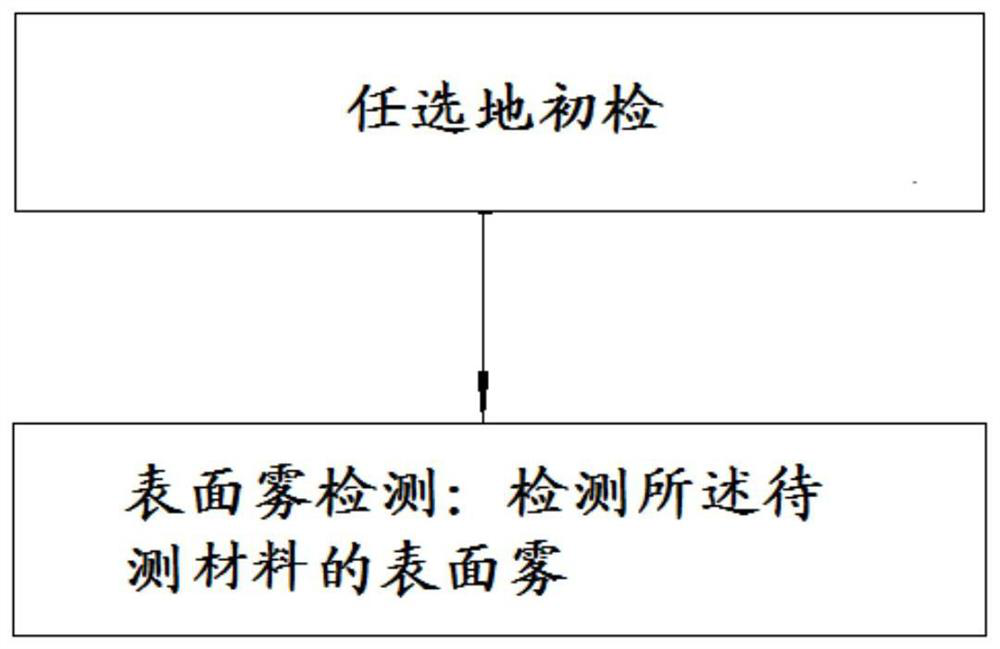

[0139] Surface haze inspection on 3-inch N-type InP (sulfur-doped) wafers. Carry out the following steps to the wafer after cleaning and drying:

[0140] 1. Initial inspection. The cleaned wafers are inspected with the strong light of Japan Yamada Optical. Adjust the illumination to not less than 400,000lx. During the lamp inspection, under the strong light, slowly rotate the wafer one circle clockwise, then slowly rotate the wafer counterclockwise for one circle, carefully observe to check whether there are visually visible defects on the wafer surface (such as scratches, potion residue, orange peel type, etc.) defect). After the wafer is confirmed to have no visual defects by light inspection, it is qualified for the initial inspection. Wafers that pass the initial inspection are used for surface fog testing.

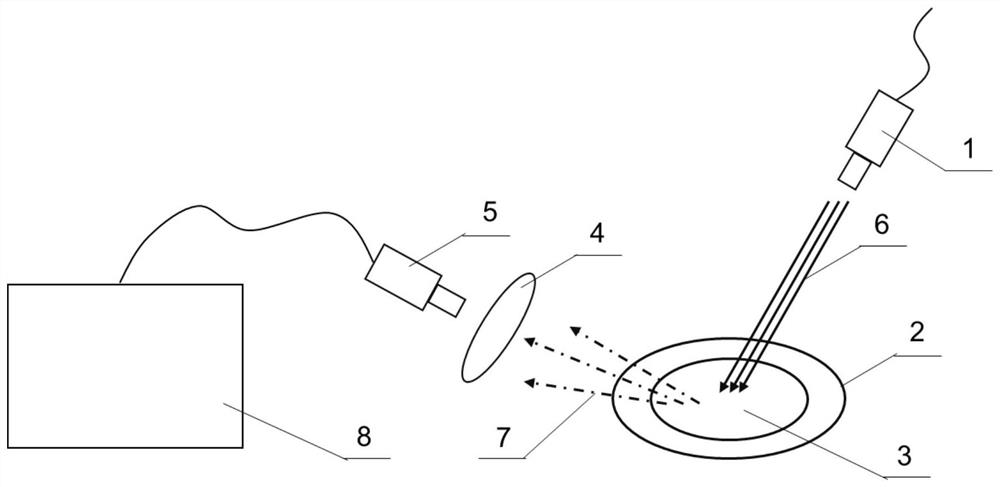

[0141] 2. Surface fog detection. The detection equipment uses the Lightspeed equipment of the 4See series of the French Unity SC company.

[0142] a. Put the w...

Embodiment 2

[0151] Surface haze inspection on 3-inch N-type InP (sulfur-doped) wafers. Carry out the following steps to the wafer after cleaning and drying:

[0152] 1. Initial inspection. The cleaned wafers are inspected with the strong light of Japan Yamada Optical. Adjust the illumination to not less than 400,000lx. The light inspection method and qualification criteria are the same as those in Example 1. Wafers that pass the initial inspection are used for surface fog testing.

[0153] 2. Surface fog detection. The detection equipment uses the Lightspeed equipment of the 4See series of the French Unity SC company.

[0154] a. Put the wafers that pass the preliminary inspection into the testing equipment and place them in the wafer loading device (wafer chuck). A blue laser with a wavelength of 473nm is used as the incident light.

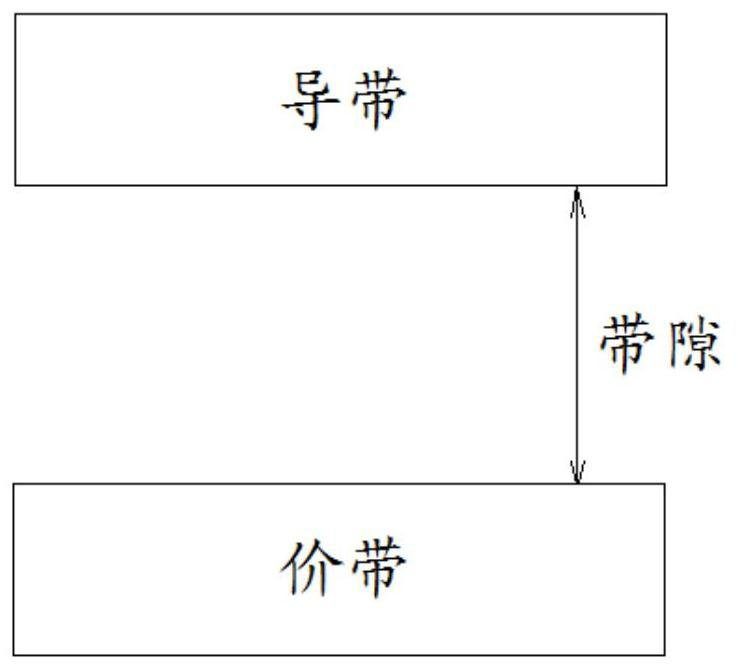

[0155] b. Select the optical filter module. Since the wafer to be tested is an InP material with a band gap of 1.35eV, the photoluminescent wavelen...

Embodiment 3

[0163] Surface fog inspection on 3-inch Un-type InP (non-doped) wafers. Carry out the following steps to the wafer after cleaning:

[0164] 1. Initial inspection. The cleaned wafers are inspected with the strong light of Japan Yamada Optical. Adjust the illumination to not less than 400,000lx. The light inspection method and qualification criteria are the same as those in Example 1. Wafers that pass the initial inspection are used for surface fog testing.

[0165] 2. Surface fog detection. The detection equipment uses the Lightspeed equipment of the 4See series of the French Unity SC company.

[0166] a. Put the wafers that pass the preliminary inspection into the testing equipment and place them in the wafer loading device (wafer chuck). A blue laser with a wavelength of 473nm is used as the incident light.

[0167] b. Select the optical filter module. Since the wafer to be tested is an InP material with a band gap of 1.35eV, the photoluminescent wavelength of the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com