Preparation method of mine bulk solid sample for laboratory

A sample preparation and laboratory technology, which is applied in the field of mine bulk sample preparation in the laboratory, can solve the problems of difficulty in the preparation of large-scale slope samples, and the research is limited to a macro perspective, and achieves wide practicability and reasonable method. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

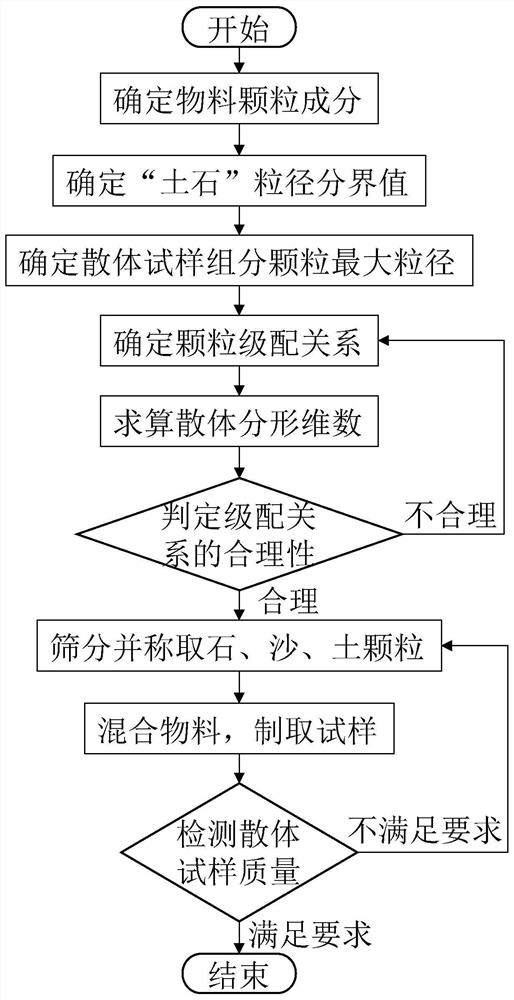

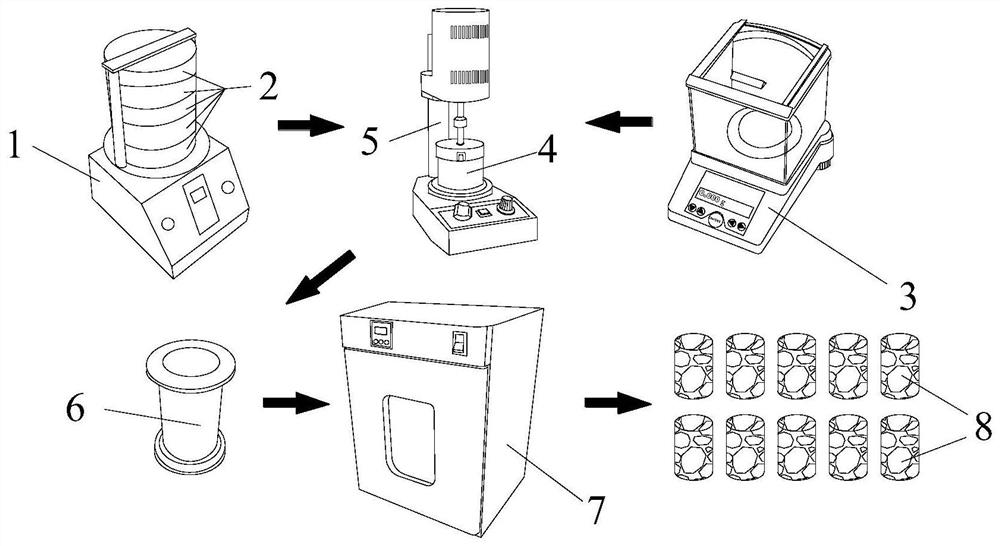

[0049] likefigure 1 figure 2 As shown, the present invention is made of a mine dispersion sample for a laboratory, comprising using a dispersion sample preparation device, a dispersion sample preparation device including a screening machine 1, a screening holder 2, an electronic balance scale 3, a mixture of materials. Box 4, high speed homogenizer 5, mold 6, and maintenance case 7, the screening space 1 is matched with a plurality of screens 2 having different destination, and is used to screen out of the desired particle diameter range material, electronics The balance scales 3 are used to weigh the quality of the materials at all levels under the designated stage, and the material mixing box 10 is used to mix the material of the weighing level of material; first, the determination of the material level relationship between the dispersion sample, with different Nuclear sieve 2 screens all levels of materials within the range of the desired particle size, and use the electronic ...

specific Embodiment

[0081] S1: Determine material particle components

[0082] Sample preparation of common mining dispersion materials in stone, soil, sand, and plastic sand, the same is used for samples;

[0083] S2: Determine "earth stone" particle size boundary value

[0084] The cylindrical dispersion sample size can be determined according to the experiment, for example: setting the size of the cylindrical dispersion sample "Earth" particle size boundary value is D S / R = 0.05 × L c = 0.05 × 50 = 2.5mm, for convenient screening, the selected dispersion material "earth" is 2mm; the particle size of the "soil" component is within 2 mm, and the particle diameter of the "stone" component is 2mm or more;

[0085] S3: Determine the maximum particle size of the dispersion sample material particles

[0086] The maximum particle size, that is, the particle size of the rock block should not be greater than

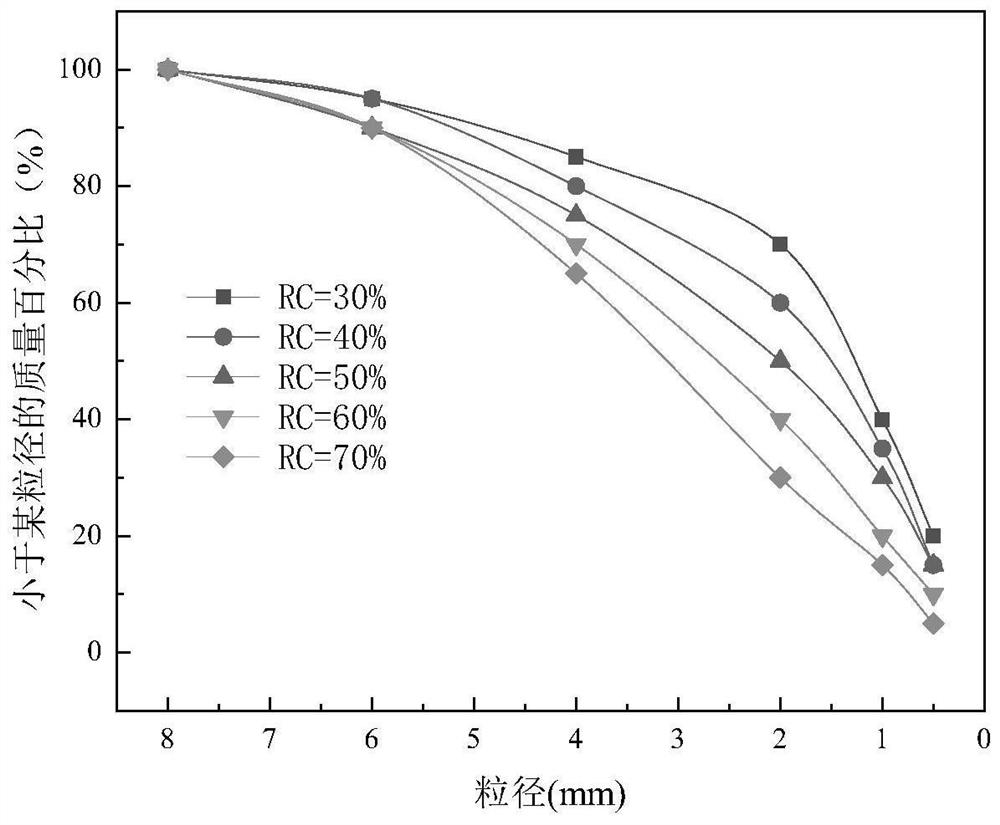

[0087] S4: Determine the particle level relationship

[0088] Take 30%, 40%, 50%, 60%, and 70% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com