Method for manufacturing large-size variable-cross-section blisk forged piece of TC17 titanium alloy

An integral blisk and TC17 technology, applied in the field of forging, can solve the problems of small deformation and uneven distribution of deformation, and achieve the effects of increased deformation, uniform distribution of deformation and improved performance of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention is further described as follows:

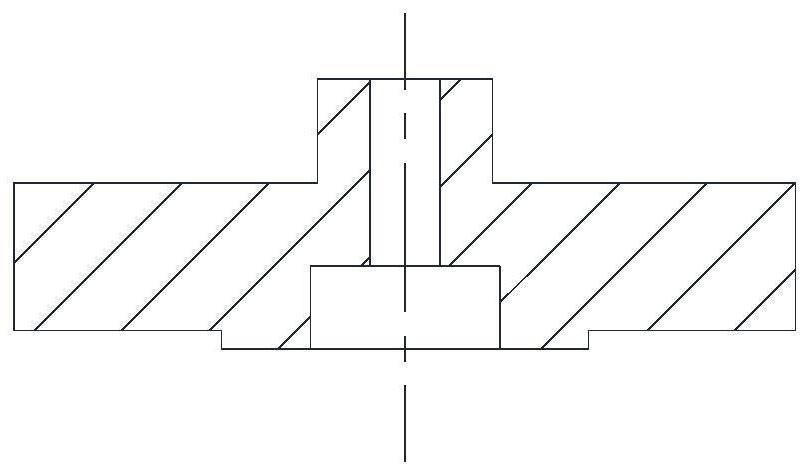

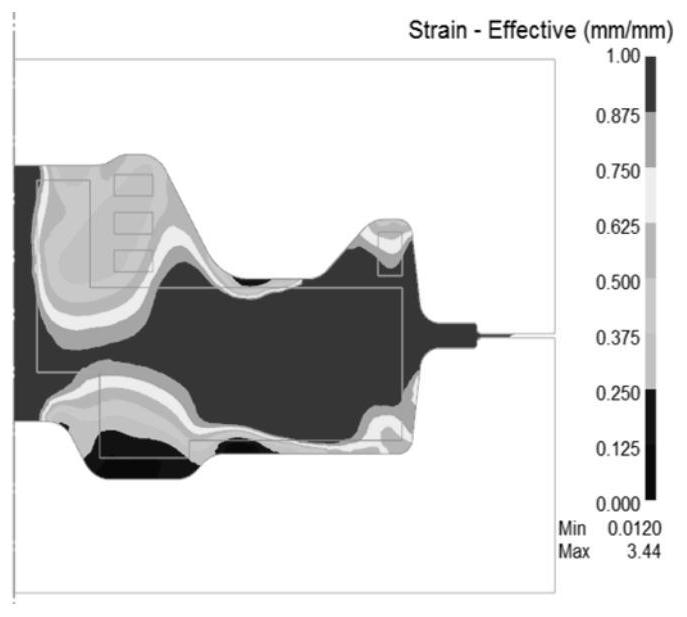

[0041] TC17 manufacturing method of large-size variable-section blisk forgings, step 1, according to the shape and size of TC17 large-size variable-section blisk parts, use digital simulation to design the best theoretical forging blank and the best theoretical blank, according to the best Theoretical forging blank design pre-forging die and final forging die.

[0042] Step 2, preparing a final forging die adapted to the best theoretical forging blank; preparing a pre-forging die adapted to the best theoretical blank;

[0043] Design the pre-forging die and final forging die according to the shape and size of the TC17 large-size variable-section integral blisk parts and the forging blank obtained from digital simulation and the best theoretical blank, so that the pre-forging die and final forging die can be forged. The shape of the forging blank is closer to the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com