High-dropping-point flame-retardant steel wire rope lubricating grease composition as well as preparation method and application thereof

A grease composition and a technology for steel wire ropes, applied in the field of grease, can solve the problems of being unsuitable for high temperature radiation conditions in steel mills, short service life of steel wire ropes, and wire rope slings, etc., and achieve excellent oxidation stability and little change in cone penetration. , the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

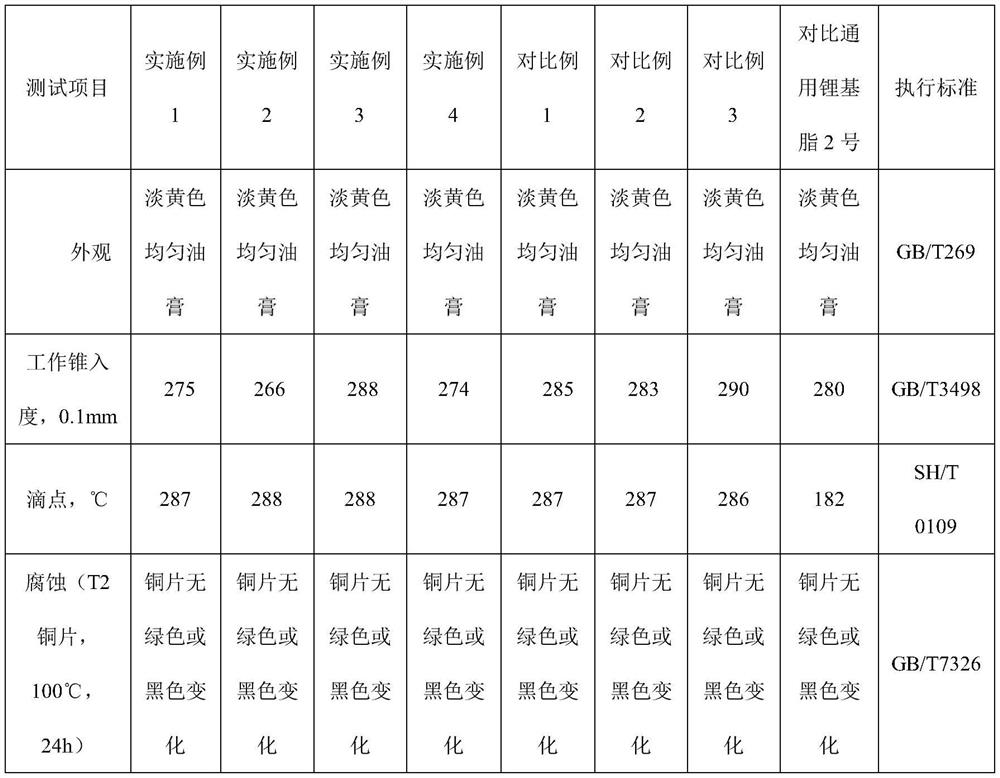

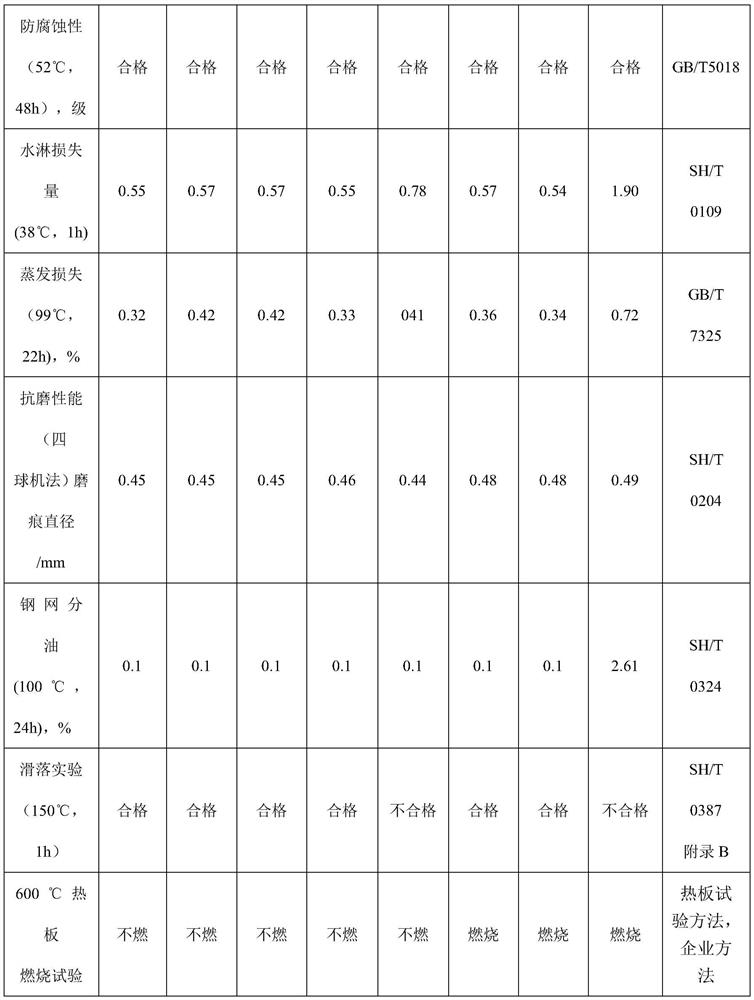

Examples

Embodiment 1

[0043] Mix 136g Wanhua Chemical MDI-100 with 553g 500SN, 744g 150BS, 553g 18B base oil and heat up to 55-65°C, stir, disperse and dissolve to obtain reactant A; mix 69g octadecylamine and 76.2g cyclohexylamine with 553g 500SN, Mix 744g of 150BS and 553g of 18B base oil and raise the temperature to 55-65°C, stir, disperse and dissolve to obtain the reactant B; mix the reactant A and the reactant B through chemical reaction to obtain a mixture of polyurea-based thickener and base oil ;Heat the mixture prepared by the reaction to the highest refining temperature of 150°C, keep it warm for 40 minutes, then cool it down to 110°C, and homogenize it under a pressure of 20MP to obtain polyurea grease; the homogenized polyurea grease Cool to 80°C and add 64g adhesive Doher-6003-RHY-615 EPDM rubber, 40g flame retardant tributyl phosphate, 40g antiwear agent tricresyl phosphate, 40g antiwear agent T361A, 20g antioxidant Irganox L135 and 8g of antirust agent barium dinonyl naphthalene sul...

Embodiment 2

[0045] Mix 154g Wanhua Chemical MDI-100 with 552g 500SN, 736g 150BS, 552g 18B base oil and heat up to 55-65°C, stir, disperse and dissolve to obtain reactant A; mix 80.79g octadecylamine and 89.18g cyclohexylamine with 552g 500SN , 736g 150BS, 552g 18B are mixed and heated to 55-65°C, stirred, dispersed and dissolved to obtain the reactant B; the reactant A and the reactant B are mixed and chemically reacted to obtain a mixture of polyurea-based thickener and base oil ;Heat the mixture prepared by the reaction to the highest refining temperature of 150°C, keep it warm for 40 minutes, then cool it down to 110°C, and homogenize it under a pressure of 20MP to obtain polyurea grease; the homogenized polyurea grease Cool to 80°C and add 64g adhesive containing Doher-6003-RHY-615 EPDM rubber, 40g flame retardant tributyl phosphate, 40g anti-wear agent tricresyl phosphate and 40g anti-wear agent T361A, 20g anti-oxidant The agent Irganox L135 and 8g of antirust agent dinonyl naphthale...

Embodiment 3

[0047] Mix 125g Wanhua Chemical MDI-100 with 561g 500SN, 748g 150BS, 561g 18B base oil and heat up to 55-65°C, stir, disperse and dissolve to obtain reactant A; mix 80.79g octadecylamine and 89.18g cyclohexylamine with 561g 500SN , 748g 150BS, 561g 18B are mixed and heated to 55-65°C, stirred, dispersed and dissolved to obtain the reactant B; the reactant A and the reactant B are mixed and chemically reacted to obtain a mixture of polyurea-based thickener and base oil ;Heat the mixture prepared by the reaction to the highest refining temperature of 150°C, keep it warm for 40 minutes, then cool it down to 110°C, and homogenize it under a pressure of 20MP to obtain polyurea grease; the homogenized polyurea grease Cool to 80°C and add 64g adhesive Doher-6003-RHY-615 EPDM rubber, 40g flame retardant tributyl phosphate, 40g antiwear agent tricresyl phosphate, 40g antiwear agent T361A, 20g antioxidant Irganox L135 and 8g of antirust agent barium dinonyl naphthalene sulfonate were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com