Coix seed and black bean fermented sauce and preparation method thereof

A fermented sauce and black soybean technology, applied in the field of seasoning sauce, can solve problems such as the limited application range of barley, and achieve the effect of promoting the denaturation of macromolecular substances, improving nutritional value and flavor, and increasing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

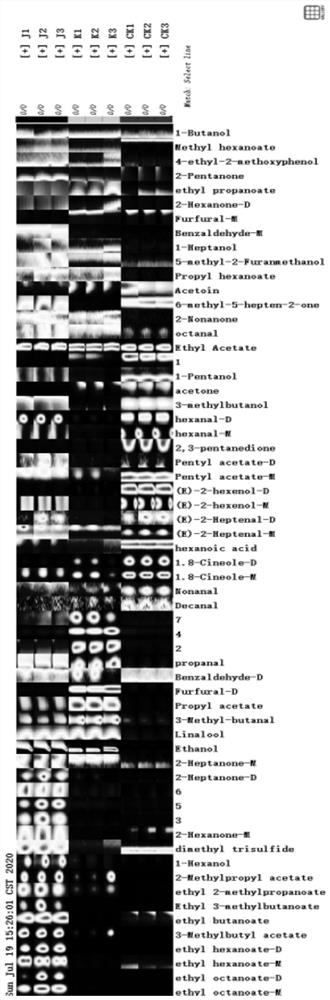

Image

Examples

Embodiment 1

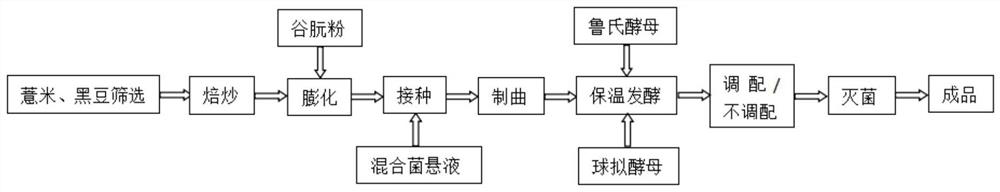

[0031] A fermented barley and black bean paste, the preparation method of which comprises the following steps:

[0032] (1) Raw material pretreatment: Roast the barley and black beans that have been screened and removed, respectively, at a roasting temperature of 200°C, and a roasting time of 4 minutes. After roasting, they are crushed and passed through a 20-mesh sieve;

[0033] (2) Expansion denaturation: The obtained coix seed powder, black soybean powder and gluten powder are processed by puffing equipment according to the mass ratio of 6:2:2. Puffing conditions: the screw speed is 400r / min, and the feed amount is 600g / min, temperature 140℃;

[0034] (3) Preparation of bacterial suspension: Aspergillus oryzae, Monascus and Corynebacterium glutamicum were prepared into 10 9 、10 7 and 10 7 The bacterial suspension of cfu / mL is then mixed according to the volume ratio of 5:3:2 to obtain a mixed bacterial suspension;

[0035] (4) Koji making: the denatured material obtain...

Embodiment 2

[0038] A fermented barley and black bean paste, the preparation method of which comprises the following steps:

[0039] (1) Raw material pretreatment: Roast the barley and black beans that have been screened and removed, respectively, at a roasting temperature of 170°C, and a roasting time of 4 minutes. After roasting, they are crushed and passed through a 10-mesh sieve;

[0040] (2) Expansion denaturation: The obtained coix seed powder, black soybean powder and gluten powder are extruded through the extruding equipment according to the mass ratio of 7:2:1. The extruding conditions: the screw speed is 300r / min, and the feed amount is 400g / min, temperature 130℃;

[0041] (3) Preparation of bacterial suspension: Aspergillus oryzae, Monascus and Corynebacterium glutamicum were prepared into 10 9 、10 7 and 10 7 The bacterial suspension of cfu / mL is then mixed according to the volume ratio of 4:3:3 to obtain a mixed bacterial suspension;

[0042] (4) Koji making: the denatured...

Embodiment 3

[0045] A fermented barley and black bean paste, the preparation method of which comprises the following steps:

[0046] (1) Raw material pretreatment: Roast the barley and black beans that have been screened and removed respectively, the roasting temperature: 260°C, the roasting time: 4min, and crush them through a 30-mesh sieve after roasting;

[0047] (2) Expansion denaturation: The obtained coix seed powder, black soybean powder and gluten powder are extruded through the extruding equipment according to the mass ratio of 8:1:1. The extruding conditions: the screw speed is 200r / min, and the feed amount is 500g / min, temperature 135℃;

[0048] (3) Preparation of bacterial suspension: Aspergillus oryzae, Monascus and Corynebacterium glutamicum were prepared into 10 9 、10 7 and 10 7 The bacterial suspension of cfu / mL is then mixed according to the volume ratio of 6:2:3 to obtain a mixed bacterial suspension;

[0049] (4) Koji making: the denatured raw material obtained in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com