Ultrahigh-temperature ceramic precursor capable of being subjected to melt spinning as well as preparation method and application thereof

A technology of ultra-high temperature ceramics and ceramic precursors, applied in the field of ceramic materials, can solve the problems of poor melting performance, poor ultra-high temperature performance, lack of anti-oxidation components, etc., and achieve good flexibility, good solubility, and excellent melting performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention proposes a method for preparing a melt-spinning ultra-high temperature ceramic precursor, comprising the following steps:

[0025] S1: Weighing Cp in proportion 2 ZrCl 2 and reducing metal filings, the Cp 2 ZrCl 2 and reducing metal filings are added to the first reaction solvent, heated and kept warm, filtered after cooling, and the equivalent active species Cp 2 Zr(II) solution;

[0026] Preferably, the Cp 2 ZrCl 2 The reaction molar ratio with reducing metal shavings is 1:3~10. In order to make Cl replaced more fully, the present invention uses excessive reducing metal shavings (Cp 2 ZrCl 2 The reaction ratio with reducing metal shavings is 1:2), among which 1:6 is better, which ensures sufficient reaction and does not cause large waste.

[0027] Preferably, the reducing metal scrap is Mg scrap; the first reaction solvent is one of anhydrous tetrahydrofuran (THF) and anhydrous N,N-dimethylformamide (DMF). When a common solvent containi...

Embodiment 1

[0041] This embodiment provides a method for preparing a melt-spinnable ultra-high temperature ceramic precursor, comprising the following steps:

[0042] S1: Weigh Cp at a molar ratio of 1:6 2 ZrCl 2 and Mg filings, the Cp 2 ZrCl 2 and Mg scraps were added to anhydrous THF, heated to 60°C for 4 hours, cooled and filtered to remove excess Mg scraps to obtain the black-purple equivalent active species Cp 2 Zr(II) solution.

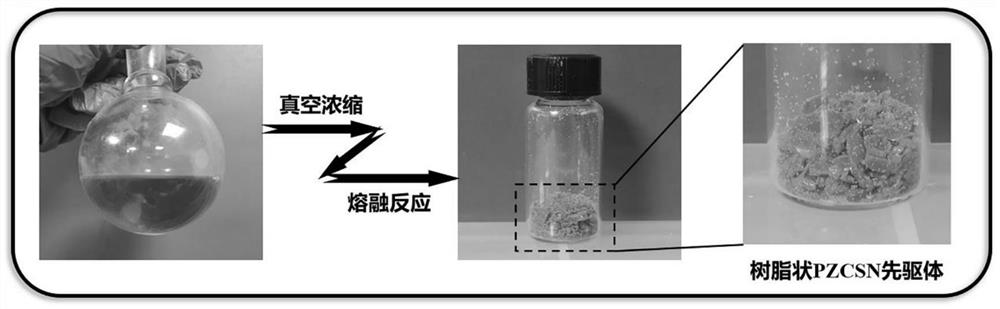

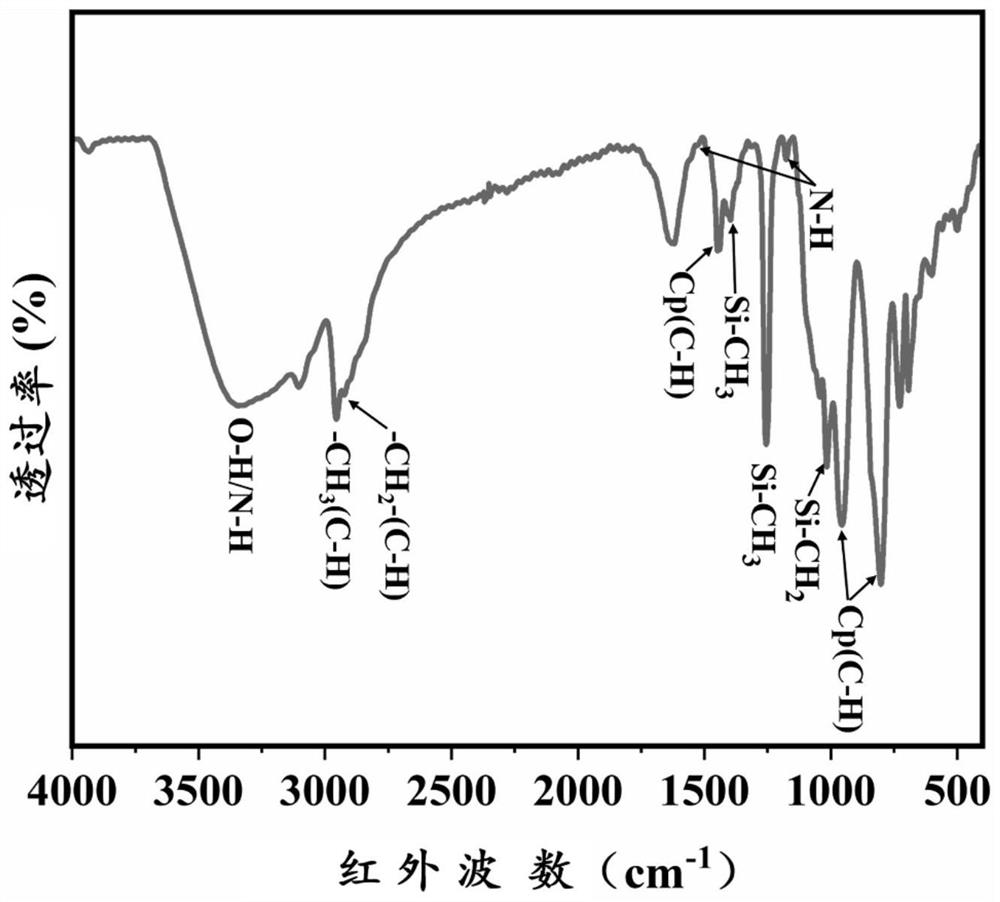

[0043] S2: Press Cp 2 Zr(Ⅱ) solution and ClCH 2 (CH 3 ) 2 Si-NH-Si(CH 3 ) 2 CH 2 The molar ratio of Cl is 5:4 to weigh ClCH 2 (CH 3 ) 2 Si-NH-Si(CH 3 ) 2 CH 2 Cl, take xylene equivalent to the above-mentioned anhydrous THF, and ClCH 2 (CH 3 ) 2 Si-NH-Si(CH 3 ) 2 CH 2 Cl and xylene are added to Cp 2 In the Zr(II) solution, stir well at room temperature, raise the temperature from room temperature to 60°C and keep it at 60°C for 10h, then raise the temperature from 60°C to 130°C and keep it at 130°C for 6h, after cooling, filter to remo...

Embodiment 2

[0049] This embodiment provides a method for preparing a melt-spinnable ultra-high temperature ceramic precursor, comprising the following steps:

[0050] S1: Same as Example 1.

[0051] S2: Same as Example 1.

[0052] S3: heating the oligomer precursor to 200° C. to make it into a molten state, reacting at 200° C. for 3 hours, and cooling to room temperature to obtain a crude product of the PZCSN ceramic precursor.

[0053] S4: Same as Example 1.

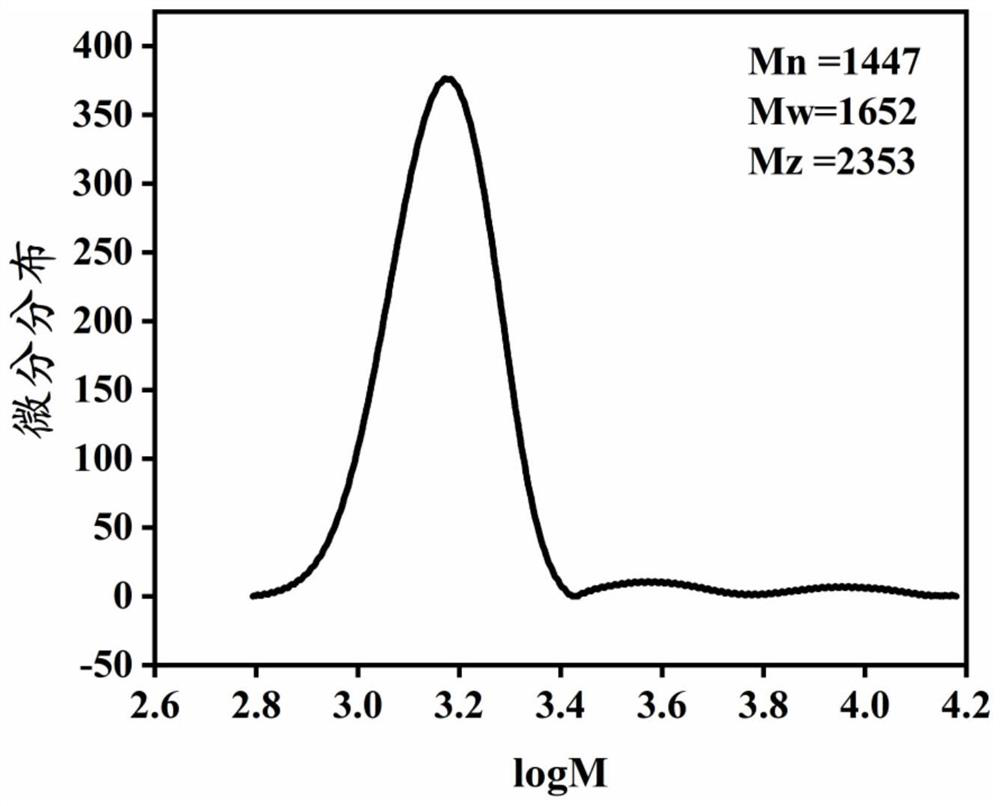

[0054] By changing the reaction time, explore the effect of melting reaction time on the structure and properties of PZCSN ceramic precursors, and found that increasing the reaction time, the softening point of the resinous precursor is 72.2-88.6 ° C, indicating that increasing the reaction time has a significant effect on the softening point of the polymer precursor Little effect, meanwhile, its ceramic yield increased to 53.62wt%. The obtained precursor is melt-spun at 130° C., and the obtained fibrils have a diameter of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com