Desiccant, sealing structure, and organic EL element

A desiccant and sealant technology, applied in the direction of drier, electrical components, electric solid devices, etc., can solve the problems of thickening of desiccant and difficulty in coating desiccant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

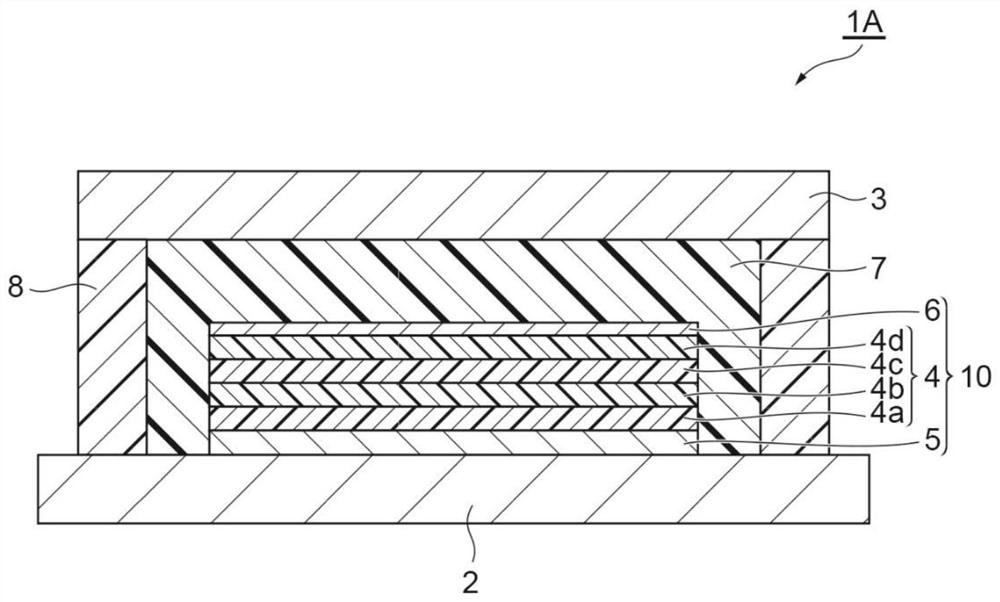

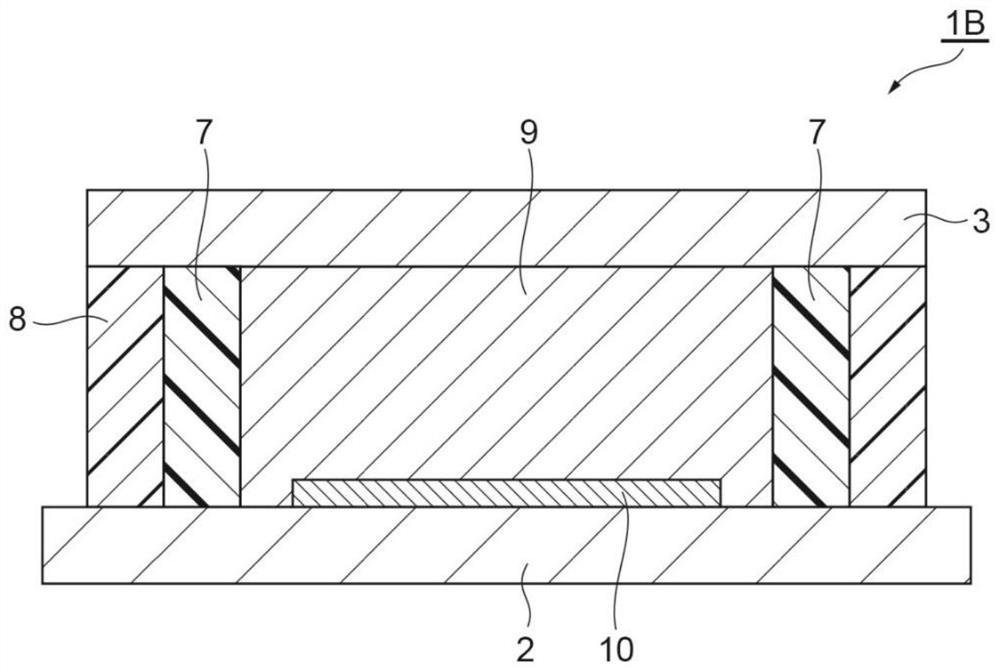

Method used

Image

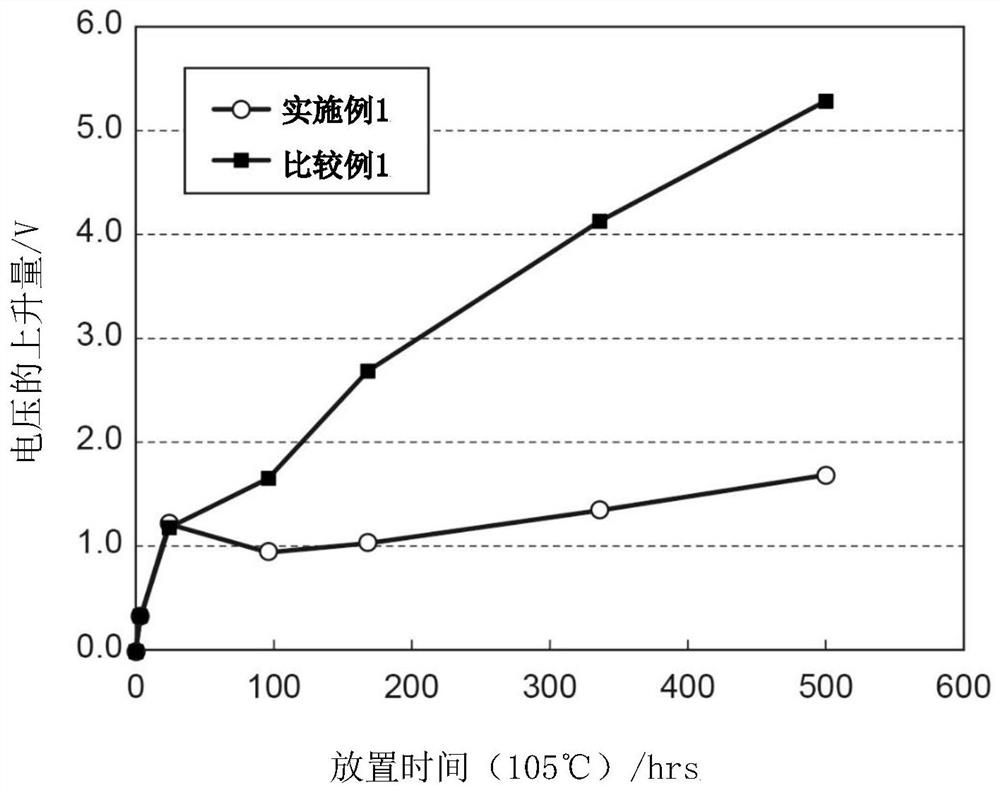

Examples

Embodiment 1

[0051] A modified fluororesin having poly(oxyperfluoropropylene) chains, siloxane groups bonded to the poly(oxyperfluoropropylene) chains, and vinyl groups bonded to the siloxane groups (Shin-Etsu Chemical Co., Ltd., product name "SIFEL8370A").

[0052] Calcium oxide particles adjusted to an average particle diameter of 2 μm and a modified fluororesin as a binder were mixed and centrifuged at 1000 rotations / min for 5 minutes to obtain a paste-like desiccant. Table 1 shows the content of calcium oxide particles based on the total amount of the desiccant in terms of mass % and grams per 1 mL of the desiccant. Table 1 also shows the theoretical value of the water absorption capacity of the desiccant obtained from the content of calcium oxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com