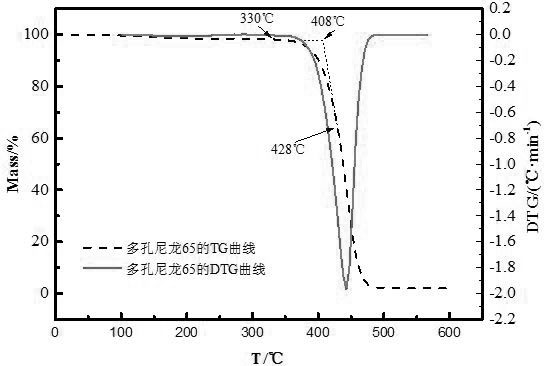

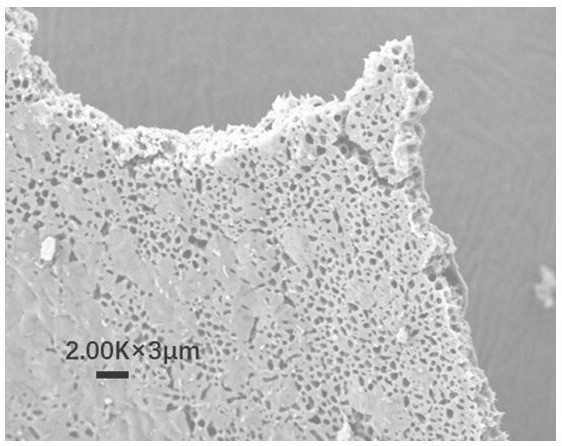

Preparation method and application of nylon 65 material with porous structure

A porous structure, nylon technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effects of improving economic benefits, convenient operation, and increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation steps of the nylon 65 material having a porous structure capable of absorbing dye wastewater in this embodiment are as follows:

[0039] Add 2g of nylon 65 sample prepared by melt polycondensation into 8g of formic acid solution to prepare a 20wt% nylon 65 formic acid solution, shake or stir at room temperature to fully dissolve the nylon 65 sample, and transfer the sample solution after fully dissolving Into a clean 30ml container prepared in advance, use a needle-hole syringe to continuously inject Na 2 CO 3 Aqueous solution (5wt% Na 2 CO 3 Aqueous solution) reacts with formic acid to prepare a nylon 65 material with a porous structure by foaming.

[0040] The prepared pore-shaped PA65 was ground and collected through an 80-mesh sieve for subsequent experiments.

[0041] The application of the nylon 65 material with a porous structure that can absorb dye wastewater in this embodiment is as follows:

[0042] Using a 50ml glass container, add the pr...

Embodiment 2

[0045] The preparation steps of the nylon 65 material having a porous structure capable of absorbing dye wastewater in this embodiment are as follows:

[0046]Add 4g of nylon 65 sample prepared by melt polycondensation to 8g of formic acid solution to prepare a 33wt% nylon 65 formic acid solution. At room temperature, shake or stir to fully dissolve the nylon 65 sample. After fully dissolving, transfer the sample solution Into a clean 30ml container prepared in advance, use a needle-hole syringe to continuously inject Na 2 CO 3 Aqueous solution (5wt% Na 2 CO 3 Aqueous solution) reacts with formic acid to prepare a nylon 65 material with a porous structure by foaming.

[0047] The prepared pore-shaped PA65 was ground and collected through an 80-mesh sieve for subsequent experiments.

[0048] The application of the nylon 65 material with a porous structure that can absorb dye wastewater in this embodiment is as follows:

[0049] Using a 50ml glass container, add the prepare...

Embodiment 3

[0052] The preparation steps of the nylon 65 material having a porous structure capable of absorbing dye wastewater in this embodiment are as follows:

[0053] Add 2g of nylon 65 sample prepared by melt polycondensation into 8g of formic acid solution to prepare a 20wt% nylon 65 formic acid solution, shake or stir at room temperature to fully dissolve the nylon 65 sample, and transfer the sample solution after fully dissolving Into a clean 30ml container prepared in advance, use a needle-hole syringe to continuously inject Na 2 CO 3 Aqueous solution (3wt% Na 2 CO 3 Aqueous solution) reacts with formic acid to prepare a nylon 65 material with a porous structure by foaming.

[0054] The prepared pore-shaped PA65 was ground and collected through an 80-mesh sieve for subsequent experiments.

[0055] The application of the nylon 65 material with a porous structure that can absorb dye wastewater in this embodiment is as follows:

[0056] Using a 50ml glass container, add the pr...

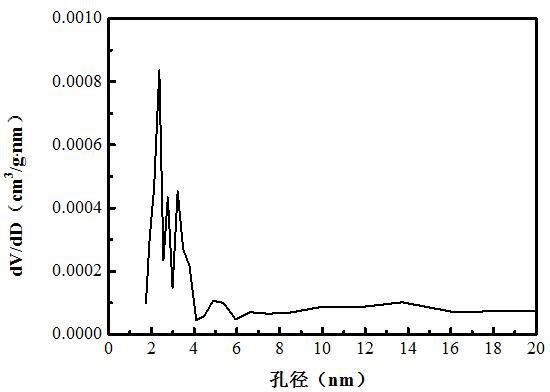

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com