Numerical control flame cutting machine based on automatic control

An automatic control, flame cutting machine technology, applied in gas flame welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of real-time inspection of material surface, lack of testing equipment, etc., to ensure cutting safety, reduce diffusion, and save energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

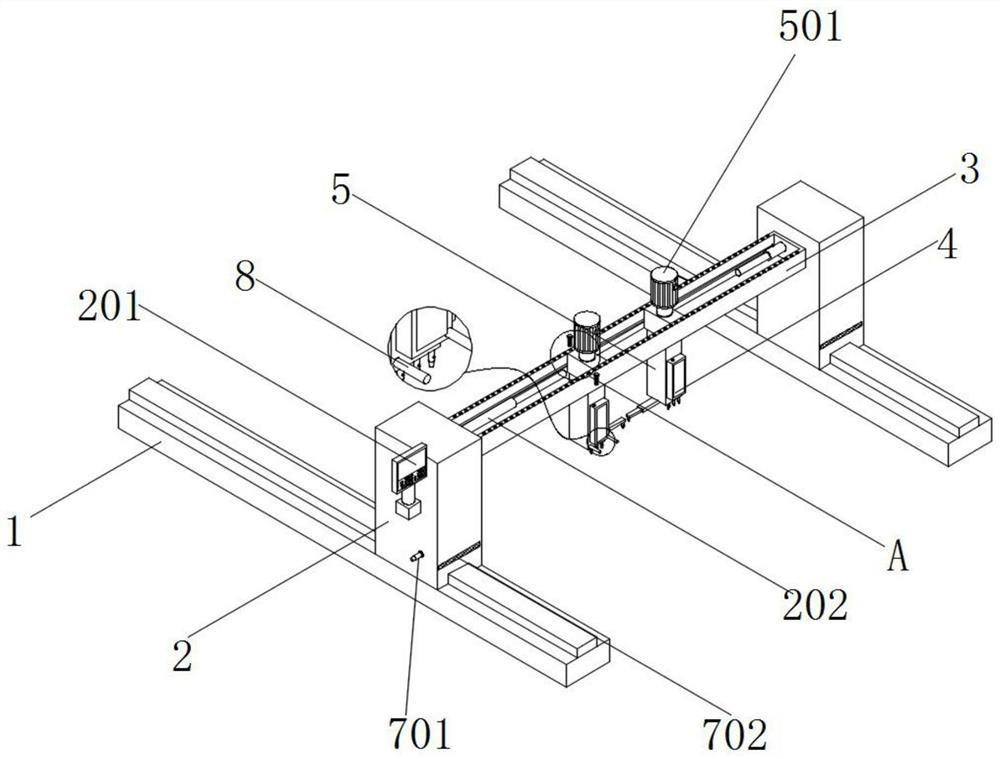

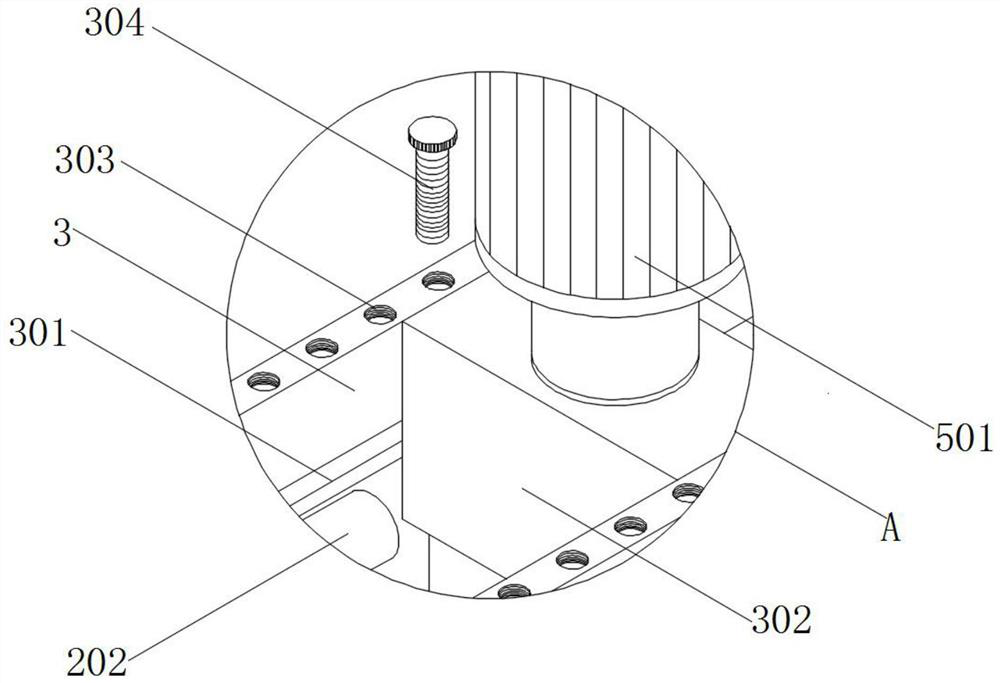

[0047] see figure 1 , Figure 4 , Figure 5 with Image 6 , a CNC flame cutting machine based on automatic control, including a slide rail bracket 1, a slide column 2 is mounted on the top of the slide rail bracket 1, and a hollow horizontal slide rail 3 is installed on the outer wall of one side of the slide column 2, and the horizontal sliding The inside of rail 3 is slidingly connected with slide block 302, and slide block 302 is made of iron material, and the bottom of slide block 302 is connected with multi-degree-of-freedom cutting torch 5, and the bottom of multi-degree-of-freedom cutting torch 5 is open design, The number of slide rail brackets 1 installed is 2;

[0048] Specifically, the section of the slide rail bracket 1 is a convex structure, which can form a tight fitting connection structure with the sliding column 2, and strengthen the fitting stability between the sliding rail bracket 1 and the sliding column 2;

[0049] Through the horizontal slide rail 3,...

Embodiment 2

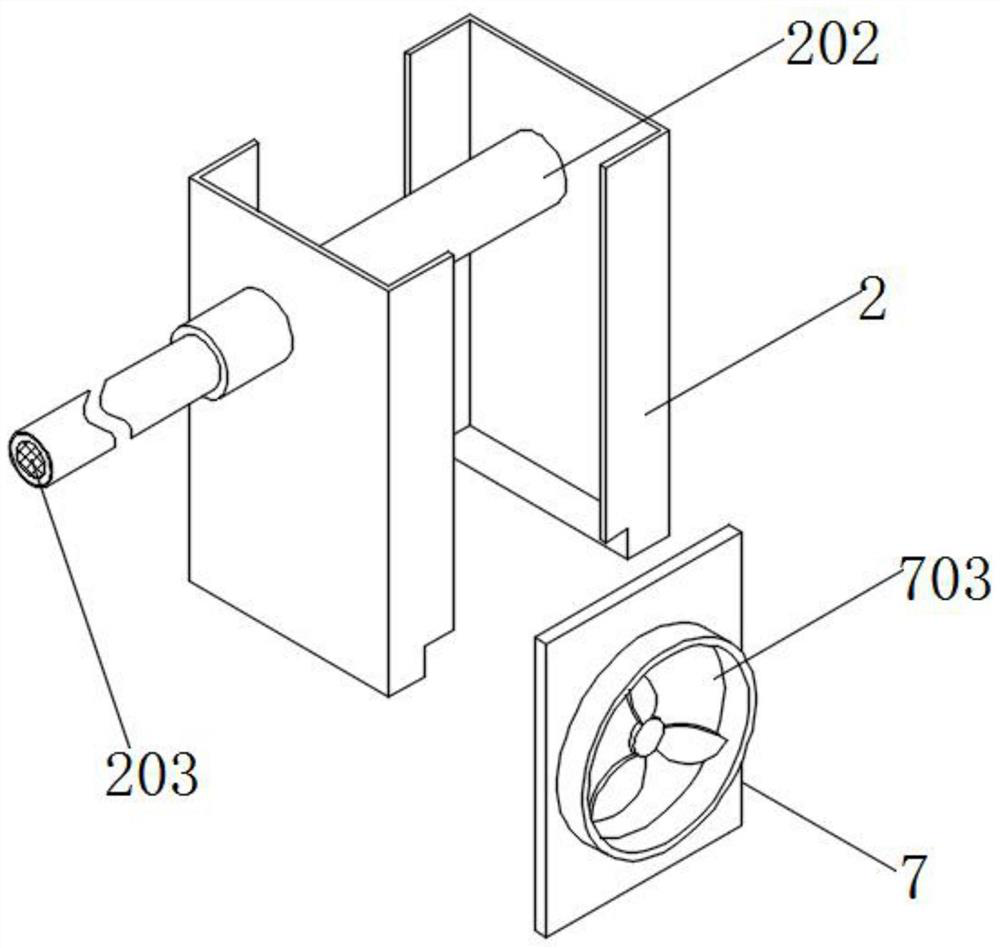

[0055] see figure 1 with figure 2 , a CNC flame cutting machine based on automatic control, including an automatic cleaning structure 7, the inner wall of the sliding column 2 is equipped with an automatic cleaning structure 7, the automatic cleaning structure 7 includes a displacement sensor 701, a ventilation net 702 and a fan 703, the sliding column 2 Partitions are installed on the inner wall of the partition, fans 703 are installed on the front and back of the partition, ventilation nets 702 are installed on the front and back of the sliding column 2 close to the slide rail bracket 1, and the outer wall on the other side of the sliding column 2 is installed with displacement The sensor 701, and the displacement sensor 701 is electrically connected with the fan 703.

[0056] Specifically, when the sliding column 2 needs to be moved, the displacement sensor 701 can detect that the sliding column 2 is in a moving state, and then send a start signal to the fan 702, thereby ...

Embodiment 3

[0058] see Figure 7 with Figure 8 , a numerically controlled flame cutting machine based on automatic control, comprising an air box 4 and an airtight tube 6, the front of a multi-degree-of-freedom cutting torch 5 is equipped with an air box 4, and one side of the outer wall of the gas box 4 is installed with an airtight tube 6, A one-way valve 601 and a sealing baffle 604 are installed inside the airtight tube 6, and the sealing baffle 604 is located on one side of the one-way valve 601, and a pressure sensor is installed on the surface of the sealing baffle 604 near the one-way valve 601 602 , an alarm 603 is installed on the top of the gas box 4 , and the alarm 603 is electrically connected to the pressure sensor 602 .

[0059] The front of air box 4 is equipped with movable box door 401 by hinge, and the back edge of movable box door 401 is all connected with sealing strip 403, and the inner bottom wall of air box 4 is placed with three groups of parallel arranged gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com