Steel structure bridge workshop primer rapid grinding device

A technology for shop primer and steel structure, applied in grinding drive device, grinding/polishing safety device, grinding/polishing equipment, etc., can solve problems such as low work efficiency, high construction risk, environmental pollution, etc., and achieve savings The effect of labor cost, reducing pollution and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

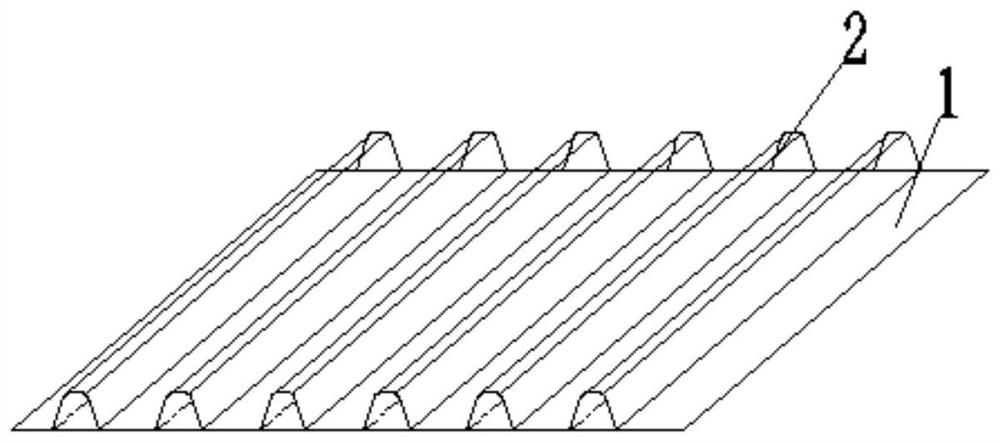

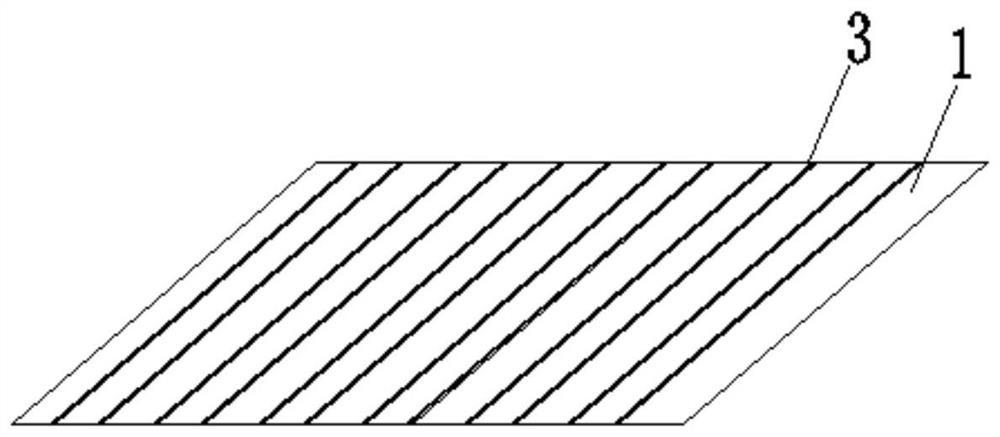

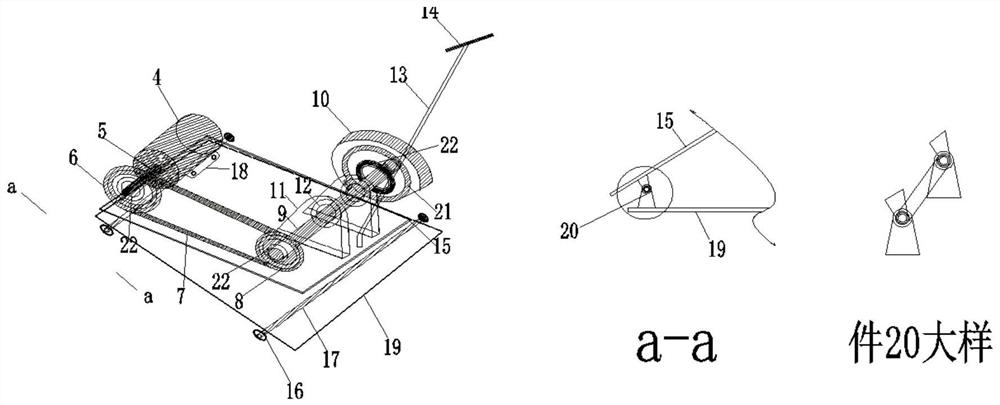

[0028] In the embodiment of the present invention, such as image 3 As shown, the manufacturing process of a primer grinding device for a steel structure bridge workshop is that a rectangular steel plate with a thickness of 16-20 mm is cut as the working base plate 15 of the device, and the size of the working base plate 15 is based on the working shaft 9 and the motor shaft. 5 and the distance between the motor 4 and the transmission shaft is calculated and determined, and at the same time, a piece of steel plate with the same thickness and width as the working base plate 15 but slightly longer than the working base plate is cut as the walking base plate 19 of the device; two working shaft base plates are connected by cutting Item 11, such as Figure 5 As shown, the central opening of the connecting piece, and the connecting bearing 12 is installed to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com