Wet type wafer cleaning device for functional ceramic wafers

A functional ceramic, wet technology, applied in surface polishing machine tools, machine tools suitable for grinding workpiece edges, grinders, etc. Improve the efficiency of cleaning tablets, reduce labor input, and improve the efficiency of cleaning tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0031] Embodiments of the invention

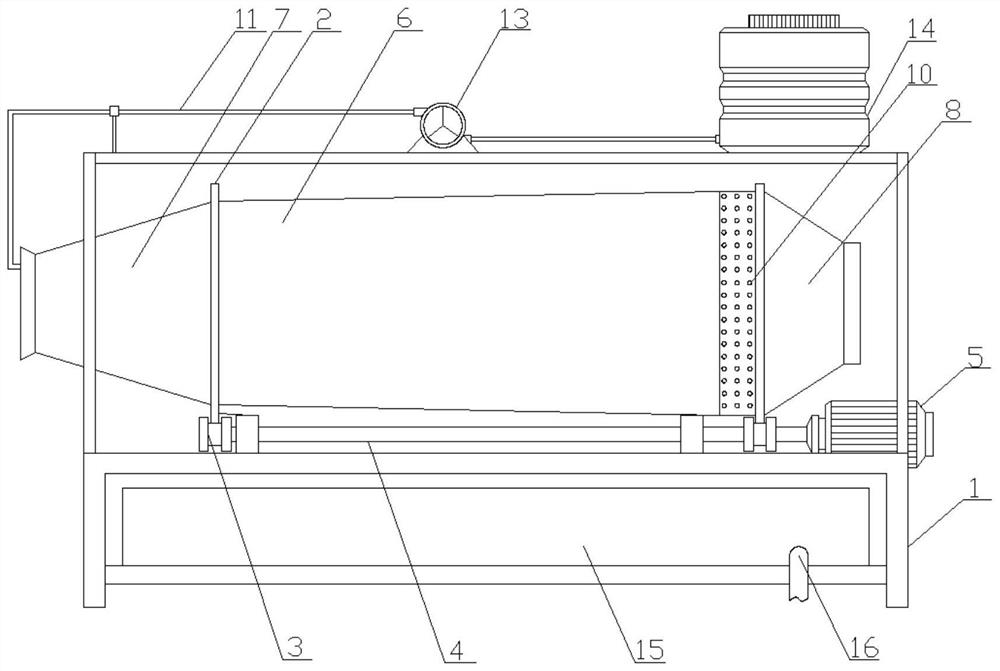

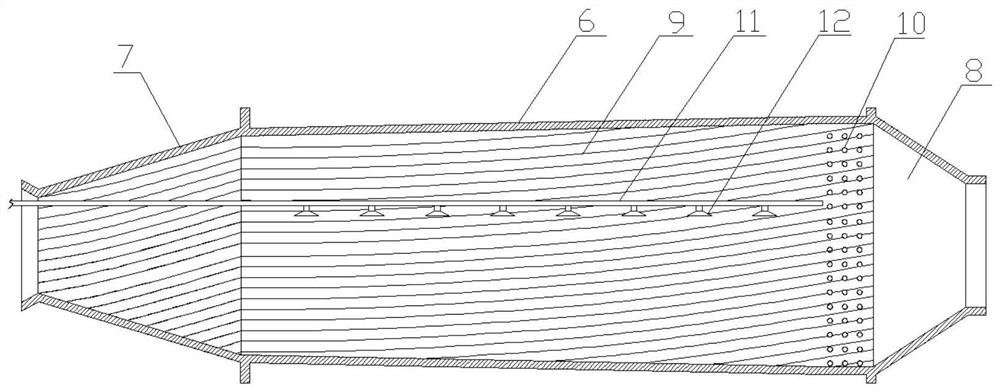

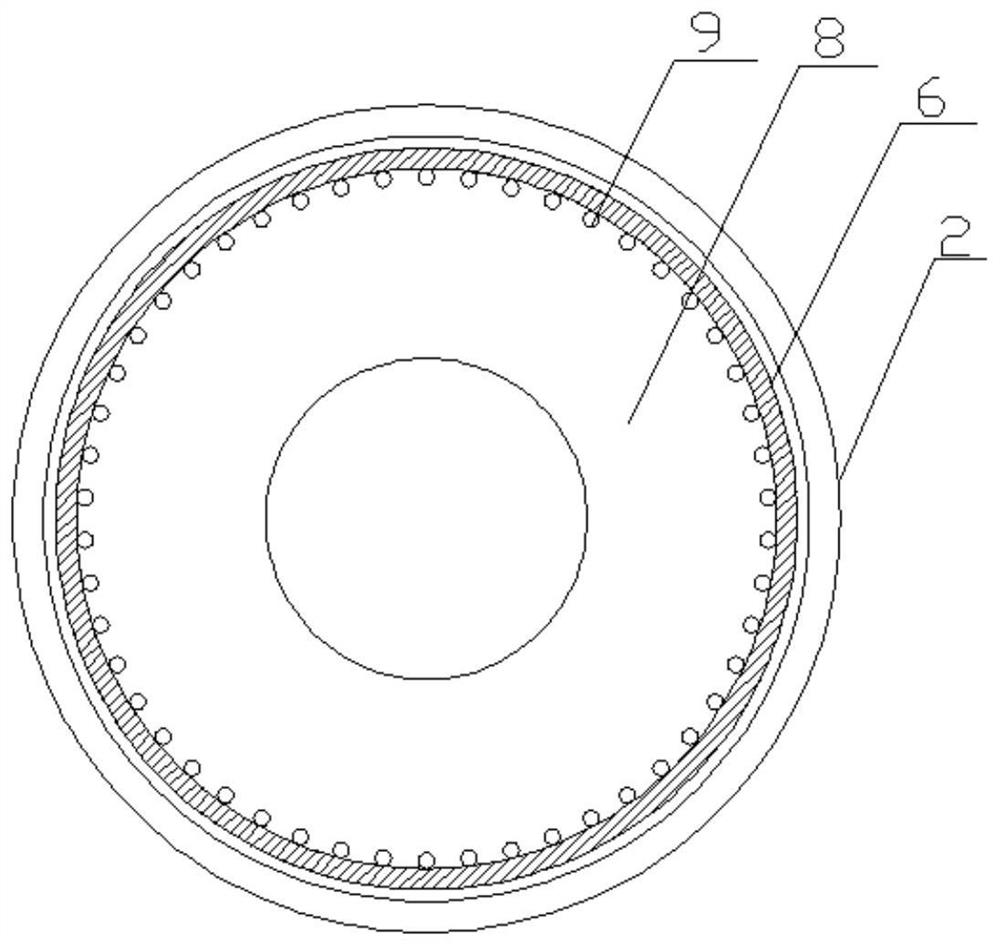

[0032] A wet cleaning device for functional ceramic sheets, as attached Figure 1-3 As shown, a bracket 1 is included, a barrel is arranged above the bracket 1, a convex ring 2 is arranged on the peripheral surface of the barrel, and a driving wheel 3 cooperating with the convex ring 2 is provided on the bracket 1 below the convex ring 2 , the driving wheel 3 is connected with a drive motor 5 through a transmission device 4; the barrel includes a clean section 6, and the two ends of the clean section 6 are respectively connected with a trumpet-shaped discharge section 7 and a feed section 8, wherein the clean The inner walls of the segment 6 and the discharge section 7 are provided with several spirally arranged ribs 9, and the distance between adjacent ribs 9 is smaller than the minimum w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com