ADC linker preparation method

A compound and reaction technology, applied in the field of compound preparation, can solve the problems such as the few records of ADClinker preparation methods, and achieve the effects of expanding production, simple and easy production methods, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of ADC linker, it comprises the following steps:

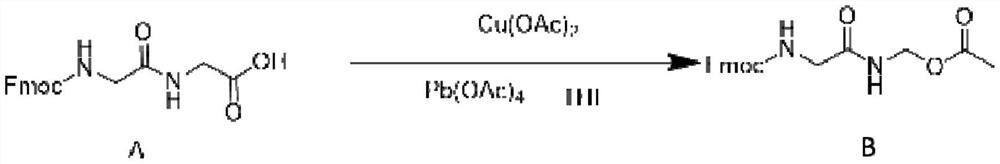

[0054] 1) With A as raw material, with copper acetate as catalyst, through N 2 Add Pb(OAc) after replacement 4 , and then prepare compound B through heating reaction;

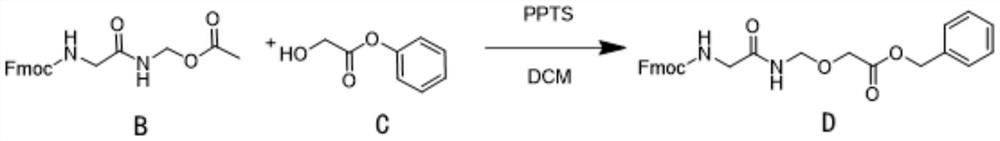

[0055] 2) Compound B, C and PPTS were added to DCM, and compound D was prepared after reflux overnight;

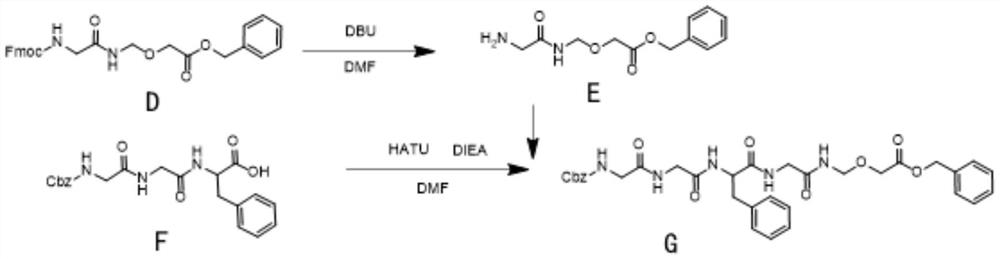

[0056]3) Add compound D in DMF, add DBU after stirring and dissolving, and remove Fmoc by stirring to obtain a solution containing E; add F, DIEA, HATU in DMF, add the solution containing E after stirring and continue to stir the reaction; Quenching the reaction, extracting, washing, drying, and concentrating under reduced pressure to obtain a creamy substance, then heating, stirring and washing, adding methyl tert-butyl ether, cooling down to crystallize, and drying to obtain G;

[0057] 4) Add DMF and Pd / C to compound G, hydrogenolyze under hydrogen atmosphere, the product is crystallized in DMF, after the reaction is comple...

Embodiment 1

[0120] A kind of preparation method of compound B, its reaction formula is,

[0121]

[0122] The method includes the following steps:

[0123] 1) Add 150gA and 20% (Cu(OAc) 2 With the molar percentage of A, the same below) Cu(OAc) 2 , N 2 Add 262.5gPb(OAc) after replacement 4 , heating the reaction at 65°C, and monitoring the completion of the reaction by TLC;

[0124] 2) Suction filtration after cooling to room temperature, the solid was washed and filtered with ethyl acetate, and the filtrate was concentrated under reduced pressure to obtain a blue oily substance;

[0125] 3) After dissolving the material obtained in the previous steps with ethyl acetate, then use saturated NaHCO 3 Washed twice with aqueous solution and once with saturated brine, Na 2 SO 4 as a desiccant to dry it;

[0126] 4) Concentrate under reduced pressure the material obtained after drying in step 3) to the quality of A, place it for crystallization, and obtain 77.8 g of solid B after suction...

Embodiment 2

[0136] A kind of preparation method of substance D, its reaction formula is,

[0137]

[0138] 1) Add 121.5 grams of B, 219.1 grams of C, 20% (the molar percentage of PPTS and B, the same below) PPTS to 1.4 LDCM, reflux overnight at 45°C, wash with brine three times, and then Na 2 SO 4 Use it as a desiccant to dry it, dissolve it at 45°C and filter it while it is hot.

[0139] 2) After the dried substance was concentrated under reduced pressure, ethyl acetate was added, dissolved at 55°C, crystallized and filtered, cooled to normal temperature and crystallized, repeated twice and then dried to obtain compound D81g. After calculation, The yield thereof was 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com