High-strength high-toughness antibacterial mildew-proof flame-retardant PC/ABS alloy material and preparation method thereof

An antibacterial, mildew-proof, high-strength and high-toughness technology, applied in the field of alloy materials and their preparation, can solve the problems of discoloration, easy conversion to brown, and the impact of PC products is reduced, and achieves high production efficiency, suitable for mass production, and high impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

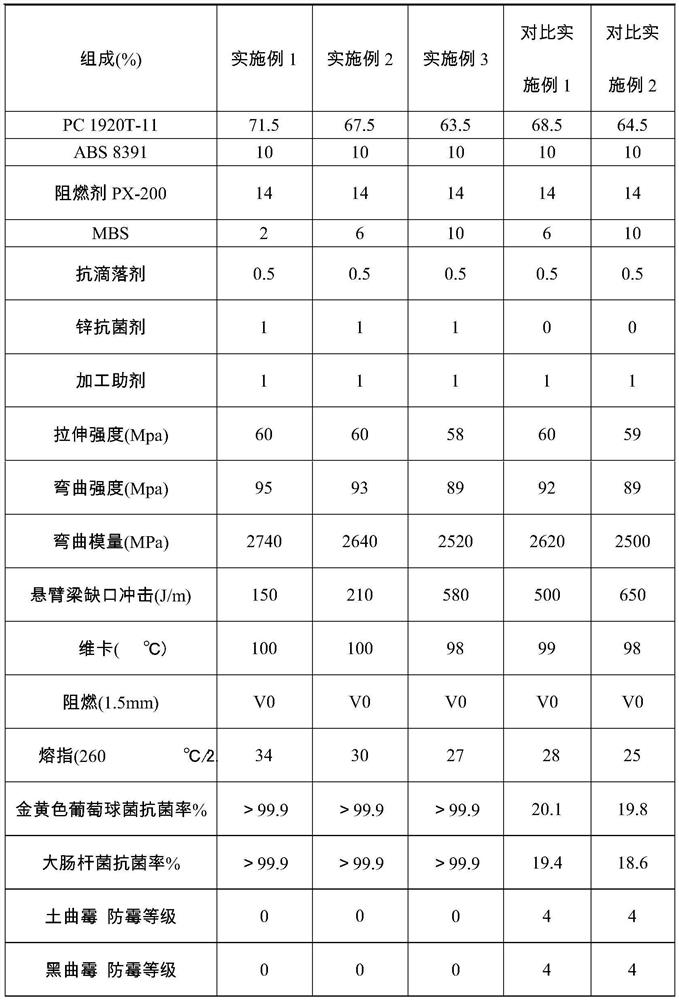

Embodiment 1

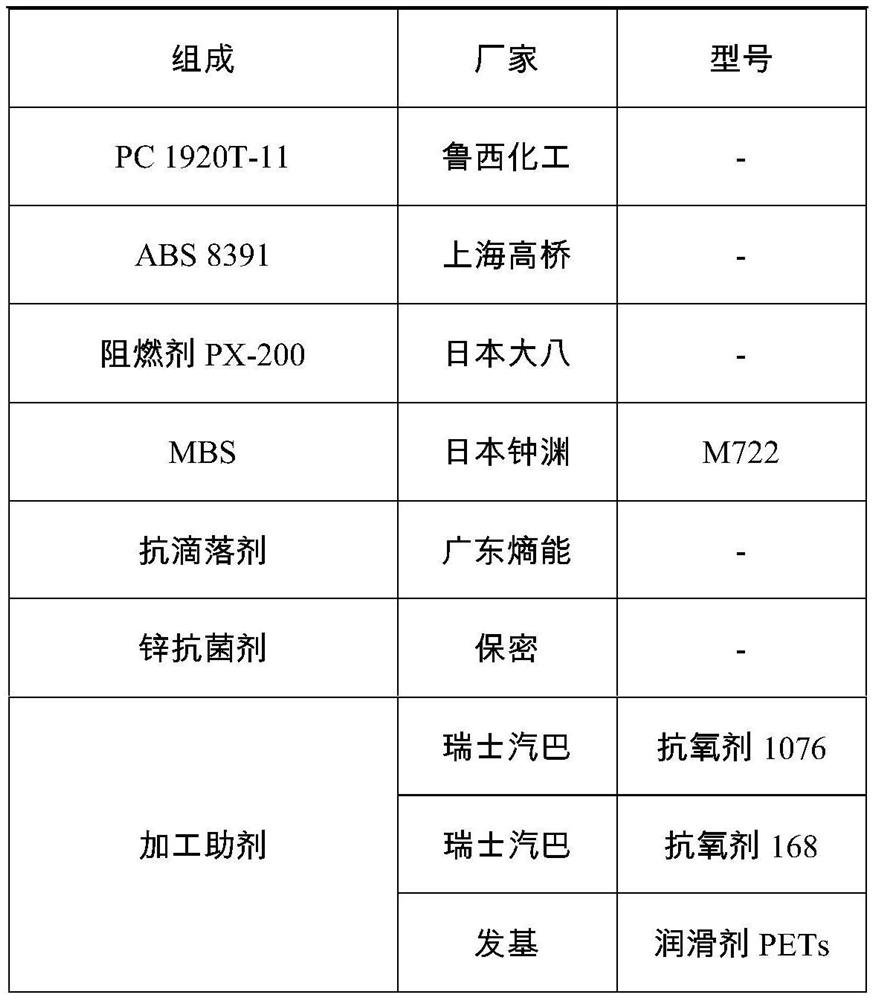

[0043] The high-strength, high-toughness, antibacterial, mildew-proof, flame-retardant PC / ABS alloy material of the present invention and its preparation method are as follows:

[0044] 71.5 parts of PC resin, 10 parts of ABS resin, 14 parts of halogen-free flame retardant PX-200, 2 parts of toughening agent, 0.5 part of anti-dripping agent, 1 part of antibacterial and antifungal agent and 1 part of processing aid (specifically Antioxidant 1076, Antioxidant 168 and lubricant PETs mixed in any proportion) are fully mixed in a high-speed mixer in proportion for 2-30 minutes; the above-mentioned mixture is transported to a twin-screw extruder through a feeding device, and the mixture is fully melted After kneading, it is extruded from the die hole of the die head, and the extruded material strip is cooled in a water tank and then pelletized to obtain the high-strength, high-toughness, antibacterial, mildew-proof, and flame-retardant PC / ABS alloy material.

[0045] Among them, the...

Embodiment 2

[0047] High-strength, high-toughness antibacterial, mildew-proof, flame-retardant PC / ABS alloy material and preparation method thereof, specifically:

[0048] 67.5 parts of PC resin, 10 parts of ABS resin, 14 parts of halogen-free flame retardant PX-200, 6 parts of toughening agent, 0.5 part of anti-dripping agent, 1 part of antibacterial and antifungal agent and 1 part of processing aid (specifically Antioxidant 1076, Antioxidant 168 and lubricant PETs mixed in any proportion) are fully mixed in a high-speed mixer in proportion for 2-30 minutes; the above-mentioned mixture is transported to a twin-screw extruder through a feeding device, and the mixture is fully melted After kneading, it is extruded from the die hole of the die head, and the extruded material strip is cooled in a water tank and then pelletized to obtain the high-strength, high-toughness, antibacterial, mildew-proof, and flame-retardant PC / ABS alloy material.

[0049] Among them, the parameters of each section...

Embodiment 3

[0051] High-strength, high-toughness antibacterial, mildew-proof, flame-retardant PC / ABS alloy material and preparation method thereof, specifically:

[0052] 63.5 parts of PC resin, 10 parts of ABS resin, 14 parts of halogen-free flame retardant PX-200, 10 parts of toughening agent, 0.5 part of anti-dripping agent, 1 part of antibacterial and antifungal agent and 1 part of processing aid (specifically Antioxidant 1076, Antioxidant 168 and lubricant PETs mixed in any proportion) are fully mixed in a high-speed mixer in proportion for 2-30 minutes; the above-mentioned mixture is transported to a twin-screw extruder through a feeding device, and the mixture is fully melted After kneading, it is extruded from the die hole of the die head, and the extruded material strip is cooled in a water tank and then pelletized to obtain the high-strength, high-toughness, antibacterial, mildew-proof, and flame-retardant PC / ABS alloy material.

[0053] Among them, the parameters of each sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com