Preparation method of acid and alkali resistant synthetic glue

A synthetic adhesive, acid and alkali resistant technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of single function and unusable industrial tapes, and achieve the purpose of suppressing the decline of mechanical properties, reducing torque, and improving surface gloss degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

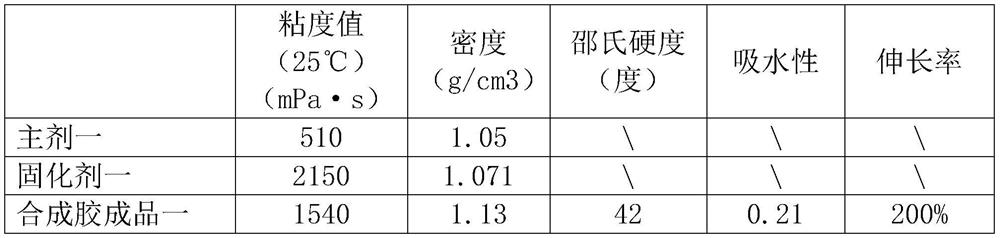

Embodiment 1

[0015] Preparation of S1 main agent one: main agent one includes alicyclic isocyanate and polyol resin, the mass ratio of alicyclic isocyanate and polyol resin is 1:5, take 20 parts of alicyclic isocyanate and 100 parts of polyol resin, Adding cycloaliphatic isocyanate and polyol resin into the reaction kettle to mix and react to obtain main agent 1;

[0016] Preparation of S2 curing agent 1: the components of curing agent 1 are 20 parts of alicyclic isocyanate, 100 parts of polyol resin, 0.024 parts of catalyst, 0.3 parts of antioxidant, 17 parts of chain extender, 56 parts of solvent, and 3 parts of anti-aging agent 8 parts, 8 parts of anti-corrosion agent, 0.7 part of anti-hydrolysis stabilizer and 0.3 part of anti-wear agent, the catalyst adopts phenylmercury acetate, and the anti-corrosion agent adopts vinyl ester resin. Take each component and add it into the reaction kettle to mix and react to obtain the curing agent- ;

[0017] Preparation of S3 synthetic rubber finis...

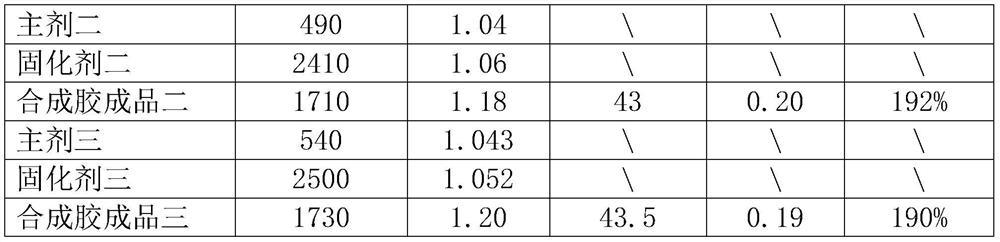

Embodiment 2

[0019] Preparation of S1 main agent two: main agent two includes alicyclic isocyanate and polyol resin, the mass ratio of alicyclic isocyanate and polyol resin is 1:5.5, take 18 parts of alicyclic isocyanate and 99 parts of polyol resin, Adding cycloaliphatic isocyanate and polyol resin into the reaction kettle to mix and react to obtain main agent 2;

[0020] Preparation of S2 curing agent 2: each component of curing agent 2 is 18 parts of alicyclic isocyanate, 99 parts of polyol resin, 0.03 part of catalyst, 0.5 part of antioxidant, 15 parts of chain extender, 61 parts of solvent, and 3 parts of anti-aging agent 9 parts, 9 parts of anti-corrosion agent, 0.75 parts of anti-hydrolysis stabilizer and 0.5 part of anti-wear agent, the catalyst adopts phenylmercury acetate, and the anti-corrosion agent adopts vinyl ester resin. Take each component and add it into the reaction kettle to mix and react to obtain curing agent 2 ;

[0021] Preparation of S3 synthetic rubber finished p...

Embodiment 3

[0023] Preparation of S1 main agent three: main agent three includes alicyclic isocyanate and polyol resin, the mass ratio of alicyclic isocyanate and polyol resin is 1:6, take 17 parts of alicyclic isocyanate and 102 parts of polyol resin, Adding cycloaliphatic isocyanate and polyol resin into the reaction kettle to mix and react to obtain the main agent three;

[0024] Preparation of S2 curing agent three: the components of curing agent three are 17 parts of alicyclic isocyanate, 102 parts of polyol resin, 0.03 parts of catalyst, 0.35 parts of antioxidant, 14 parts of chain extender, 52 parts of solvent, and 4 parts of anti-aging agent 9 parts, 9 parts of anti-corrosion agent, 0.8 part of anti-hydrolysis stabilizer and 0.35 part of anti-wear agent, the catalyst adopts phenylmercury acetate, and the anti-corrosion agent adopts vinyl ester resin. Take each component and add it into the reaction kettle to mix and react to obtain curing agent 3 ;

[0025] Preparation of S3 synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com