Method for reducing content of plasticizer in tea seed oil

A technology of tea seed oil and plasticizer, applied in the field of edible oil, can solve the problems of polluting water resources, atmosphere, soil, etc., and achieve the effects of low cost, simple operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

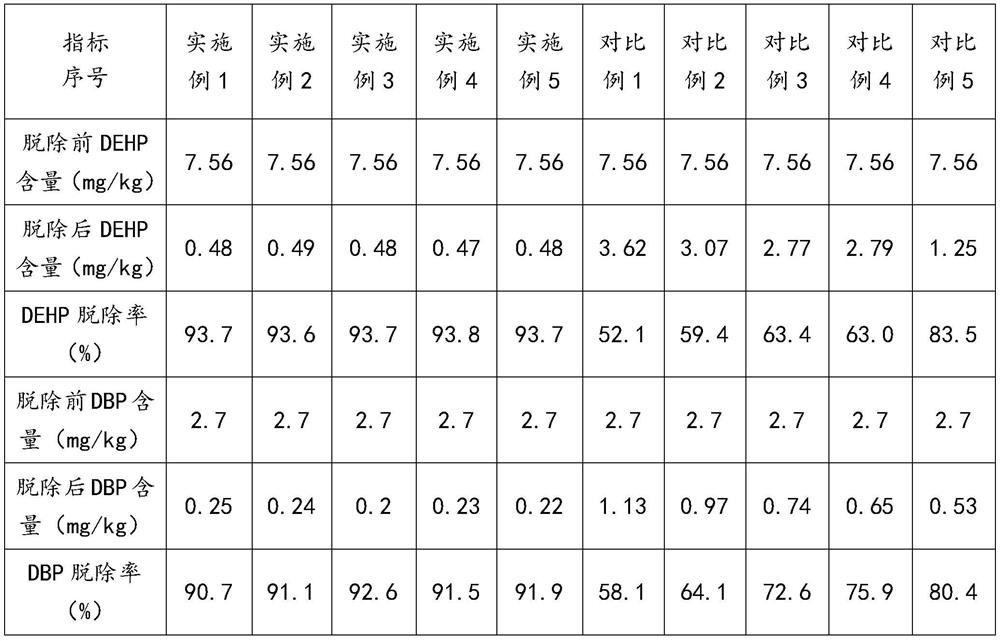

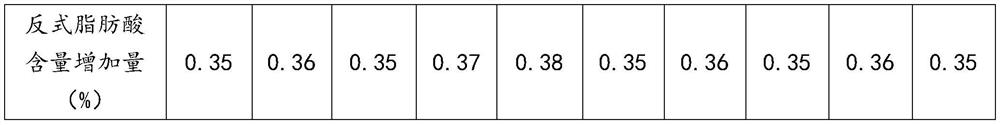

Examples

Embodiment 1

[0026] The tea seed oil was placed in a water vapor distillation apparatus, and stirred and controlled the rotational speed of 30R / min. Vapor is distilled, controls the flow of saturated water vapor 2.0sLpm, ensuring that tea seed oil will not splash, heat insulation for 20 min; then warm to 280 ° C, heat insulation 50min, last cooling to 240 ° C, heat insulation 20 min, stop access, full of saturated water Vapor; condense and collect the steaming gas, after cooling, after cooling to room temperature, at normal pressure, it is to remove the teasee oil after the plasticizer.

Embodiment 2

[0028] The tea seed oil was placed in a water vapor distillation apparatus, and stirred and the rotational speed was 35 r / min, and the vacuum to the pressure was 110 Pa. First, heated tea seed oil to 250 ° C, and the saturated water vapor was transferred into the teasee oil. Distillation, the flow rate of saturated water vapor is 3SLPM to ensure that tea seed oil will not splash in the device; then heat it up to 300 ° C, heat insulation for 60 min, last cooling to 250 ° C, heat insulation for 30 min, stop accessing saturated water vapor, The steaming gas is condensed by a condenser and collects; after cooling to room temperature, the treated tea seed oil is collected at normal pressure, which is to remove the teasee oil after the plasticizer.

Embodiment 3

[0030] The tea seed oil was placed in a water vapor distillation apparatus, and the stirring was turned on and the rotational speed was 40r / min, and the vacuum to the pressure of 120Pa, first heated teaseed oil to 240 ° C, to the teaseed oil to pass the saturated water vapor Distillation, control of saturated water vapor flow rate 4.0slpm, ensuring that tea seed oil does not splash in the device, heat insulation for 20min; then warmed to 300 ° C, heat insulation 50min, last cooling to 240 ° C, heat insulation for 20 min, stop accessing saturated water vapor, The steamed gas is condensed into a liquid through a condenser and collects the oil temperature after cooling to room temperature, and the treated tea seed oil is collected at normal pressure to obtain the teaseed oil after the plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com