Sterile workshop for food production

A workshop and food technology, applied in applications, household heating, household appliances, etc., can solve problems such as poor sterilization effect, easily polluted workshop, bacteria accumulation, etc., to improve the quality of production hygiene and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

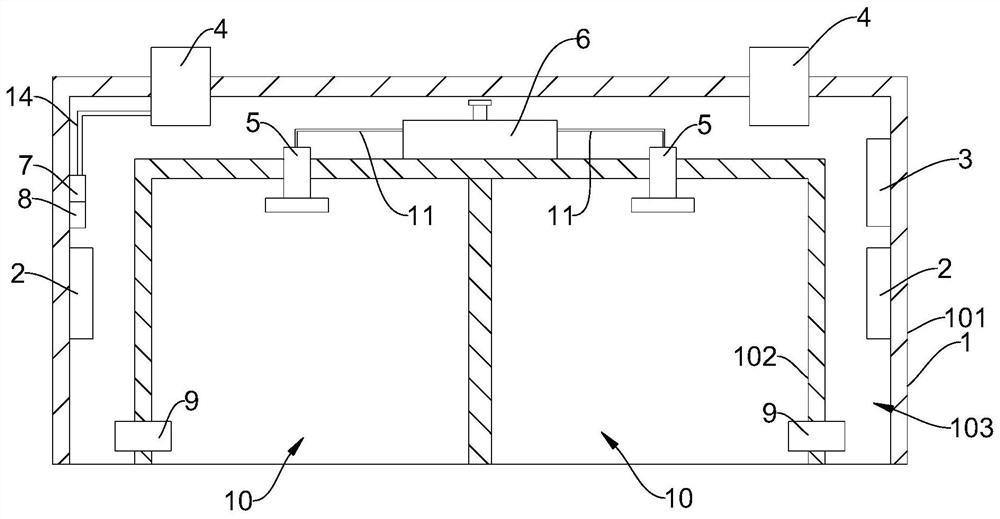

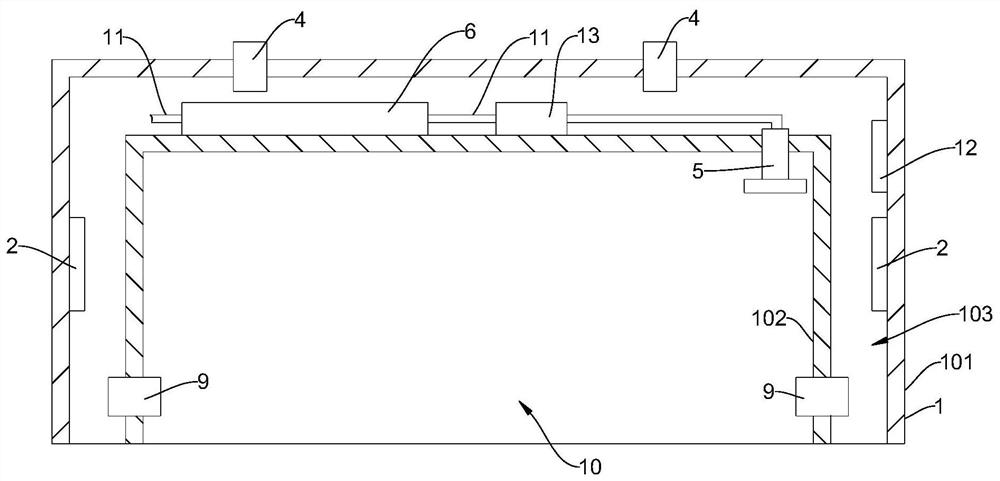

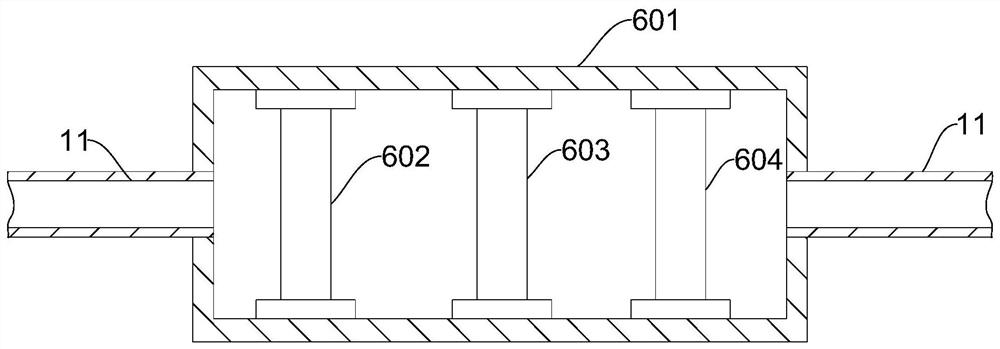

[0035] Please refer to figure 1 , figure 2 with Figure 4 , figure 1 Shown is the structural representation of the embodiment of the present invention; figure 2 It is a schematic cross-sectional view of an embodiment of the present invention; Figure 4 It is a schematic structural diagram of the workshop in the embodiment of the present invention. This embodiment provides an aseptic workshop for food production, including a clean board 1. The above-mentioned clean board 1 uses a medium-density fiber cement board as a base material, uses UV paint as a raw material, and uses a UV light curing process to coat the surface of the board. decorate. Attach UV paint coating on the surface of the board, through the irradiation of ultraviolet light, it will be cured instantly to form a film, and the curing content is high, the hardness is high, the board surface is smooth and smooth, and it has good antibacterial ability. The above-mentioned clean board 1 forms a sealed workshop,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com