Pouch-type battery case and pouch-type secondary battery

A battery case, bag-type technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc., can solve the problem of reducing the energy efficiency of secondary batteries, increasing the dead space of secondary batteries, and the size of electrode assemblies. Reduce problems such as excellent puncture strength, improve moldability, increase tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

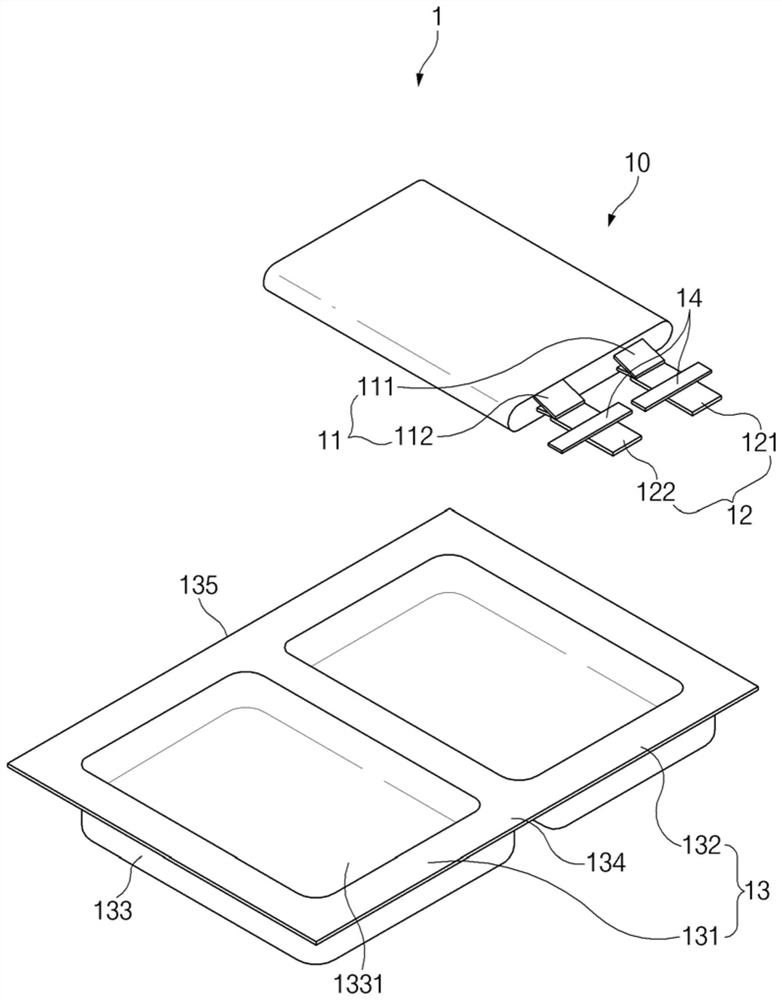

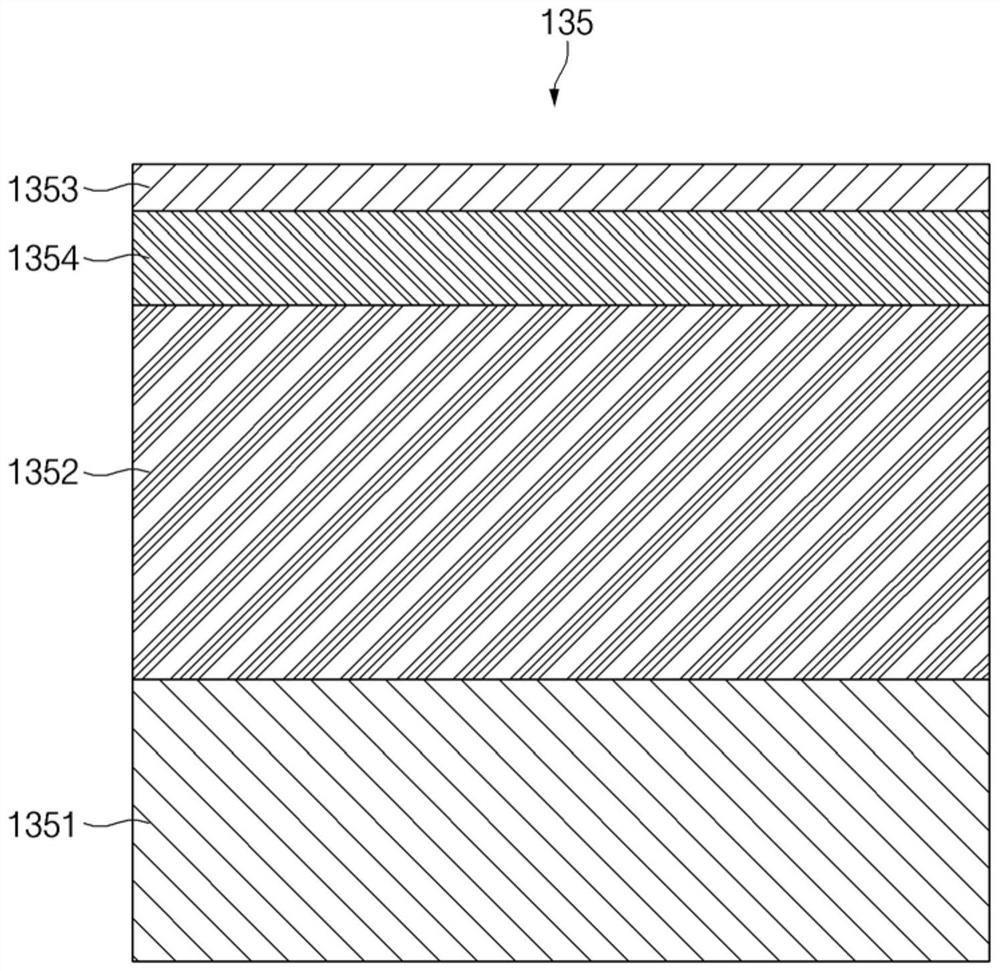

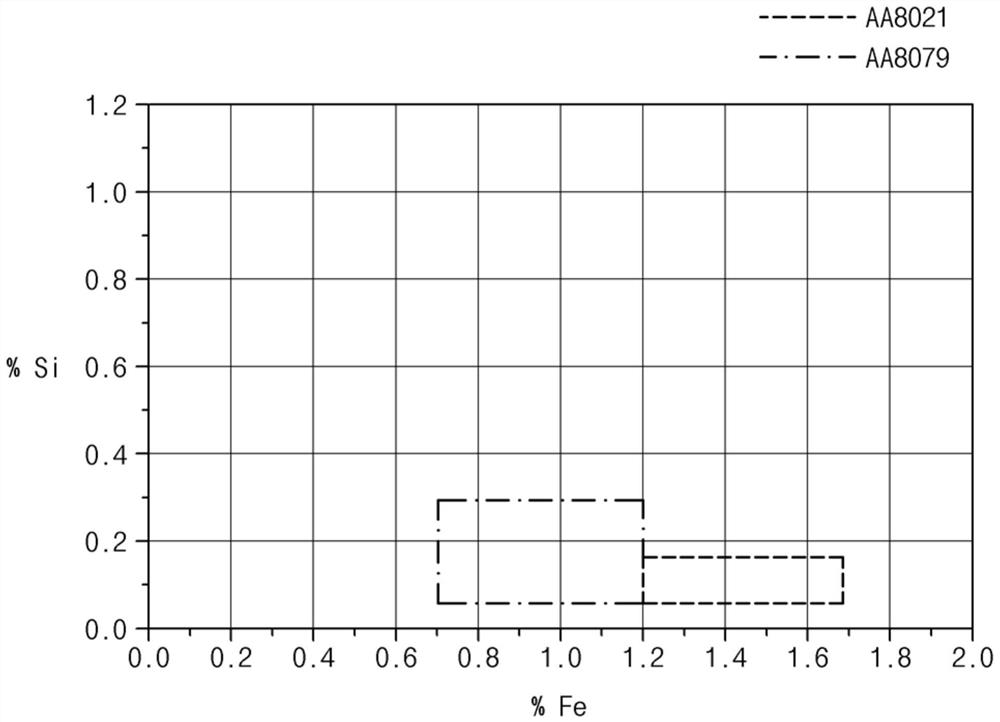

[0082] A nylon resin with a width of 266 cm, a length of 50 m, and a thickness of 25 μm and a polyethylene terephthalate (PET) with a width of 266 cm, a length of 50 m, and a thickness of 12 μm were sequentially laminated on a surface with a width of 266 cm and a length of 266 cm. AA8021 aluminum (Al) alloy with a width of 266 cm, a length of 50 m, and a thickness of 60 μm was laminated on the other surface of AA8021 aluminum (Al) alloy. On the surface.

[0083] Here, nylon and aluminum (Al) alloys are bonded to each other by dry lamination by using a conventional polyurethane (Urethane) adhesive, and cast polypropylene (CPP) with excellent electrolyte resistance is Melted under, then co-extruded and laminated on an aluminum (Al) alloy to produce a bag film according to a production example of the present invention. Here, aluminum (Al) alloy forms the gas barrier layer, PET forms the surface protection layer, nylon forms the tensile auxiliary layer, and CPP forms the sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com