Die-casting forming equipment for intelligent manufacturing

A die-casting and intelligent manufacturing technology, applied in the field of die-casting and forming equipment for intelligent manufacturing, can solve the problems of slow self-cooling and cooling of workpieces, inconvenient collection, storage and processing, and inability to process continuous processes, so as to shorten the cooling time, use Safe and convenient, the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

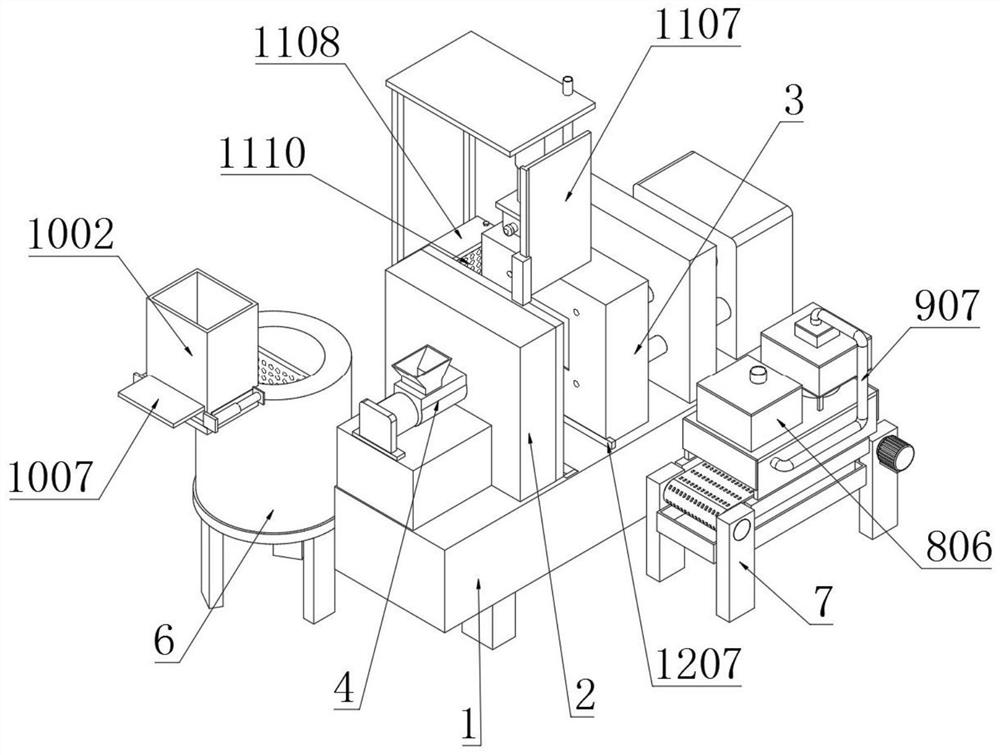

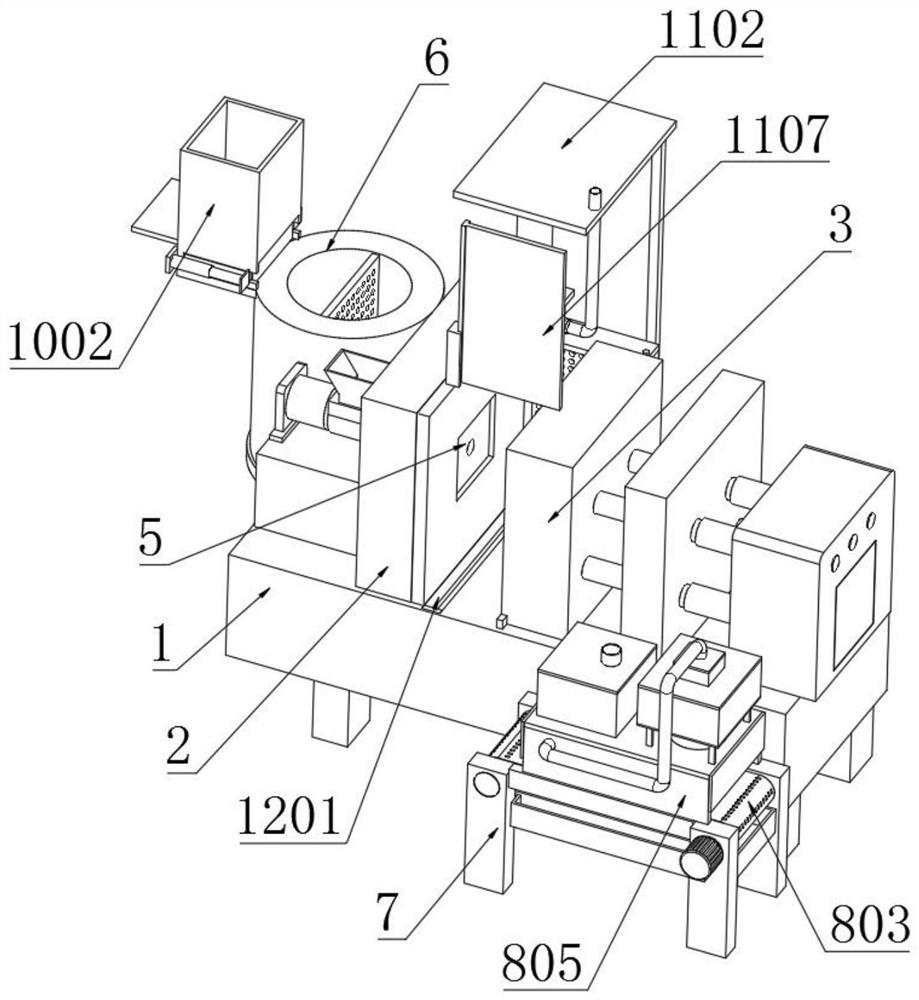

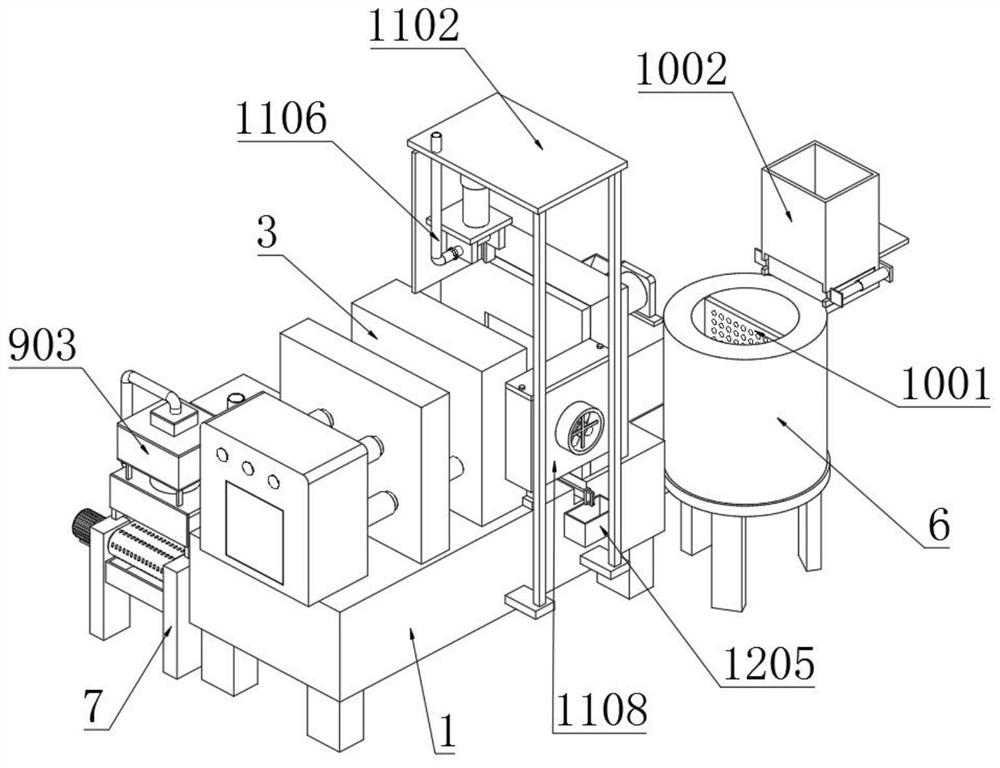

[0039] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a die-casting equipment for intelligent manufacturing, including a base 1, one end of the top of the base 1 is fixedly installed with a static mold base 2, and the top end of the base 1 away from the static mold base 2 is movably installed There is a movable mold base 3, an injector 4 is fixedly installed at one end of the middle part of the static mold base 2, a mold cavity 5 is opened in the middle part of the static mold base 2, a melting furnace 6 is fixedly installed at one end of the base 1, and one side of the middle part of the base 1 A support frame 7 is fixedly installed, and a spray cooling mechanism 8 is fixedly installed on the top of the support frame 7. The spray head 809 is used to spray water on the surface of the workpiece for cooling and cooling, and the brush 811 will clean the surface;

[0040] The spray cooling mechanism 8 includes a rotating shaft 801, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com