A kind of high-performance al-ti-v-b alloy refiner and its preparation method and application

An al-ti-v-b, refiner technology, applied in the field of aluminum alloy processing, can solve the problems of changing furnace temperature, cumbersome process, reducing refining efficiency, etc., to improve industrial production, simplify the preparation process, and improve the refining effect. Effect

Active Publication Date: 2022-05-31

JILIN UNIV

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the ability of Al-V-B to refine α-Al grains needs to be improved, and the existing process for preparing Al-V-B refiners is relatively cumbersome, requiring multiple changes in furnace temperature, and consumes a lot of energy

The new Al-Nb-B refiner also has good refinement ability but NbAl 3 , NbB 2 Equal refinement particles are easy to settle and fail, making the refinement effect unstable or even invalid

In addition, the Al-Ti-Nb-B refining agent developed and prepared by the patent number CN108220703A can refine the grain size of α-Al to below 450 μm, however, (Ti,Nb)B 2 and (Ti,Nb)Al 3 Agglomeration of particles may reduce refinement efficiency, remains to be resolved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1A

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

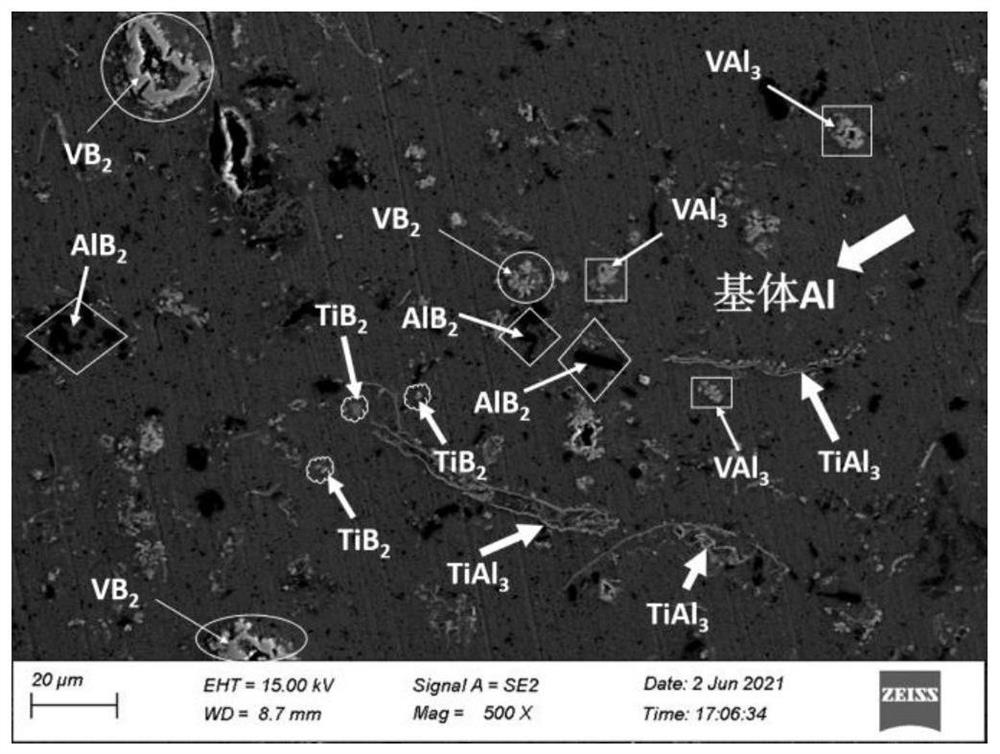

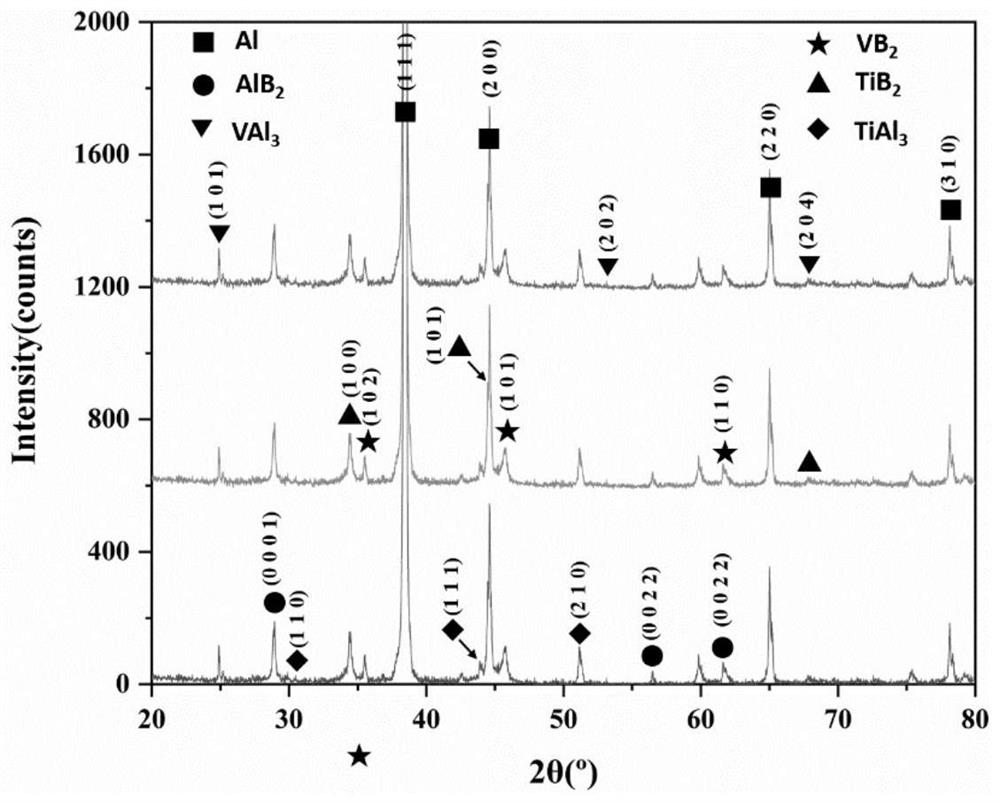

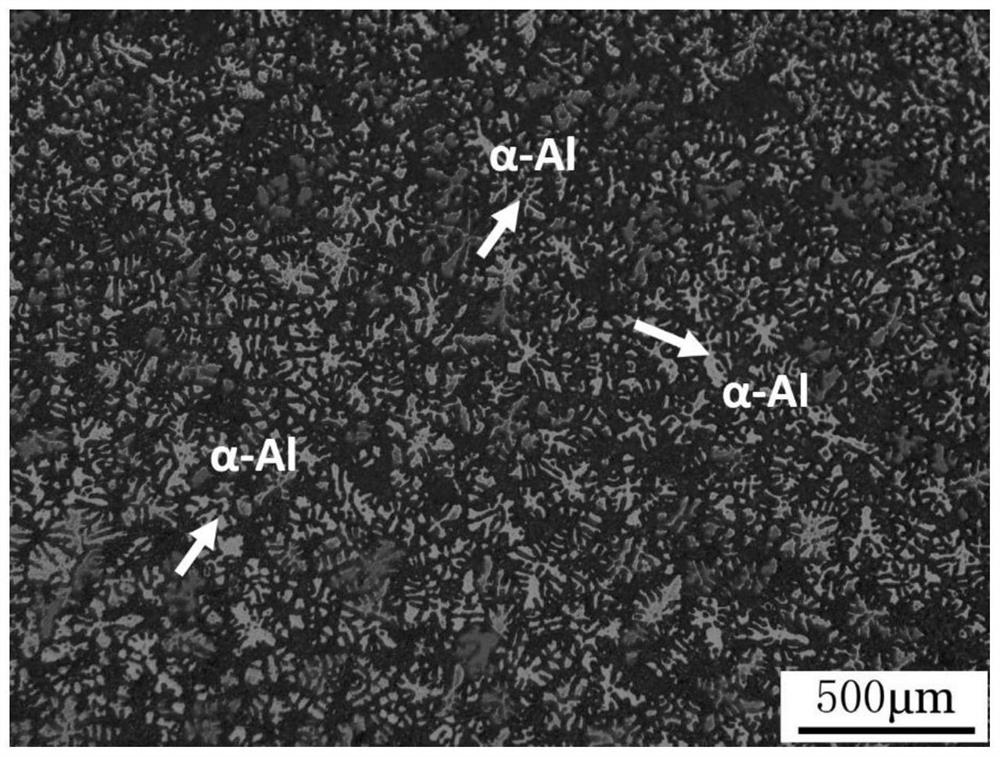

The invention discloses a high-performance Al-Ti-V-B alloy refiner and its preparation method and application. The chemical element composition of the Al-Ti-V-B alloy is: Ti: 0.5-3.0 wt. %, V: 1.0-4.0 wt.%, B: 1.0-6.0 wt.%, unavoidable impurities less than 0.1%, the balance Al, Al-Ti-V-B alloy is composed of Al matrix and the size is 1-100μm TiAl3, VAl3, VB2, TB2 and AlB2 phase particles. The Al-Ti-V-B refining agent prepared by methods such as melting, heating, blending, stirring and pouring can refine the grain size of α-Al in the cast aluminum-silicon alloy to below 160 μm; therefore the Al of the present invention The ‑Ti‑V‑B alloy has a remarkable refining effect on α‑Al grains in the cast aluminum-silicon alloy, has a simple preparation method and low cost, and is suitable for large-scale industrial production.

Description

A high-performance Al-Ti-V-B alloy refiner and its preparation method and application technical field The invention belongs to aluminum alloy processing technical field, relate in particular to a kind of high-performance Al-Ti-V-B alloy refiner and Its preparation method and application. Background technique Due to its excellent casting properties and better mechanical properties, cast aluminum-silicon alloys are widely used in automobiles, rail transit, construction It is widely used in the fields of construction and aerospace. Grain refinement of cast Al-Si alloys plays an important role in improving the microstructure density and The effect of mechanical properties is significant, and it is of great significance to further expand its application range. At present, the most commonly used industrial casting aluminum alloys It is Al-5Ti-B refiner. However, in Al-Si alloys with Si content greater than 5 wt.%, due to the poisoning effect of Si element, This reduce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/00C22C1/06C22C1/10C22C1/03

CPCC22C21/00C22C21/003C22C1/1036C22C1/06

Inventor 贾海龙薛利文朴一男赵玉桥赵海冬曲岩查敏王慧远

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com