TPE composition for coating luggage cloth and preparation method of TPE composition

A composition and coating technology, applied in the direction of textiles and papermaking, etc., can solve problems affecting the service life of bags, shedding, cracking of TPE coating, etc., to prolong service life, improve tensile strength, enhance aging resistance and durability The effect of tear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

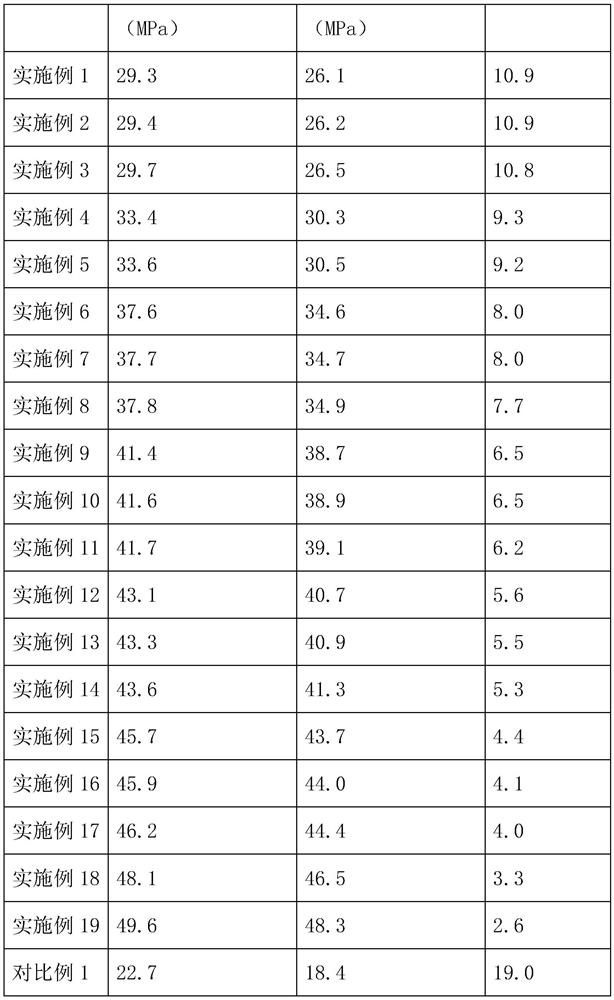

Examples

Embodiment 1

[0060] A kind of TPE composition for bag cloth coating is prepared by the following steps:

[0061] Step 1: Add 105kg of TPE, 5.7kg of phenylalanine, 4.6kg of dicyclohexylmethane diisocyanate, 3.2kg of potassium stearate, and 2kg of coumarone resin into the high-mixer, and control the temperature at 80°C. After mixing evenly, obtain the first mixture;

[0062] Step 2: Add the first mixture to a twin-screw extruder for extrusion granulation. The screw speed is 300r / min, the temperature is controlled at 225°C, and the material is discharged after cooling for 20s to obtain a TPE composition for bag cloth coating.

Embodiment 2

[0064] A kind of TPE composition for bag cloth coating is prepared by the following steps:

[0065] Step 1: Add 127kg of TPE, 1.3kg of phenylalanine, 12.8kg of dicyclohexylmethane diisocyanate, 0.4kg of potassium stearate, and 7kg of coumarone resin into the high-mixer, and control the temperature at 100°C. After mixing evenly, After cooling for 20s, the material is discharged to obtain the first mixture;

[0066] Step 2: Add the first mixture to a twin-screw extruder for extrusion granulation. The screw speed is 300r / min, the temperature is controlled at 195°C, and the material is discharged after cooling for 20s to obtain a TPE composition for bag cloth coating.

Embodiment 3

[0068] A kind of TPE composition for bag cloth coating is prepared by the following steps:

[0069] Step 1: Add 111kg of TPE, 2kg of phenylalanine, 5.9kg of dicyclohexylmethane diisocyanate, 2.8kg of potassium stearate, and 3.2kg of coumarone resin into the high-mixer, and control the temperature at 95°C. After mixing evenly, obtain the first mixture;

[0070] Step 2: Add the first mixture to a twin-screw extruder for extrusion granulation. The screw speed is 300r / min, the temperature is controlled at 200°C, and the material is discharged after cooling for 20s to obtain a TPE composition for bag cloth coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com