Intelligent coal mine underground gas extraction device

A gas extraction and coal mine technology, which is applied in the field of underground gas extraction devices in coal mines, can solve the problems of wasting resources, polluting the environment, leakage, etc., and achieves the effects of avoiding sealing performance, reducing leakage, and improving extraction concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

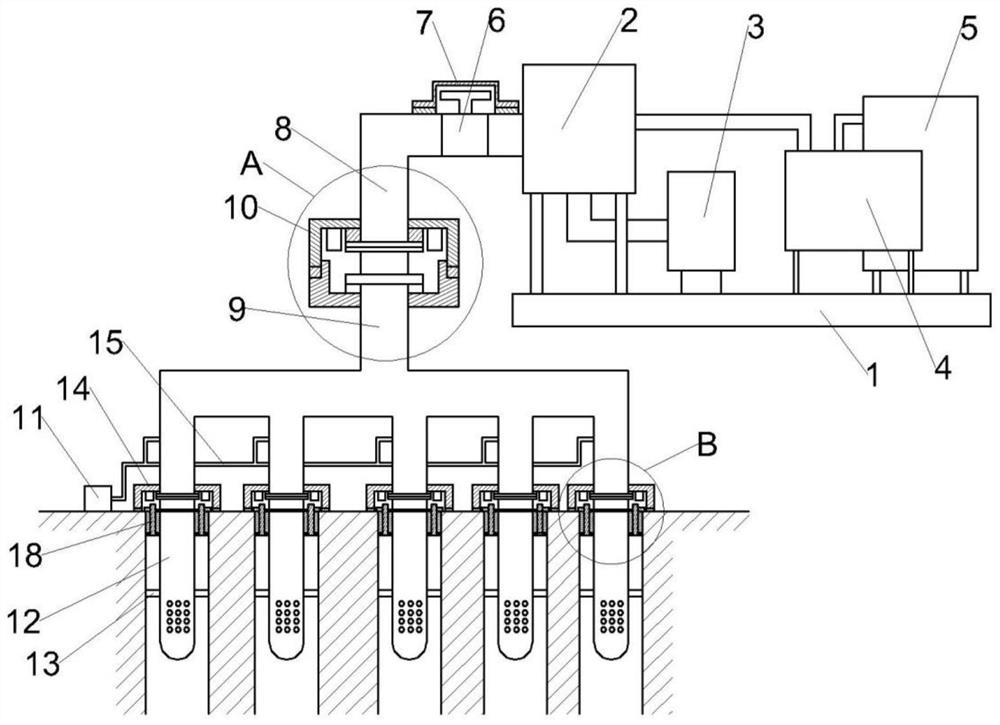

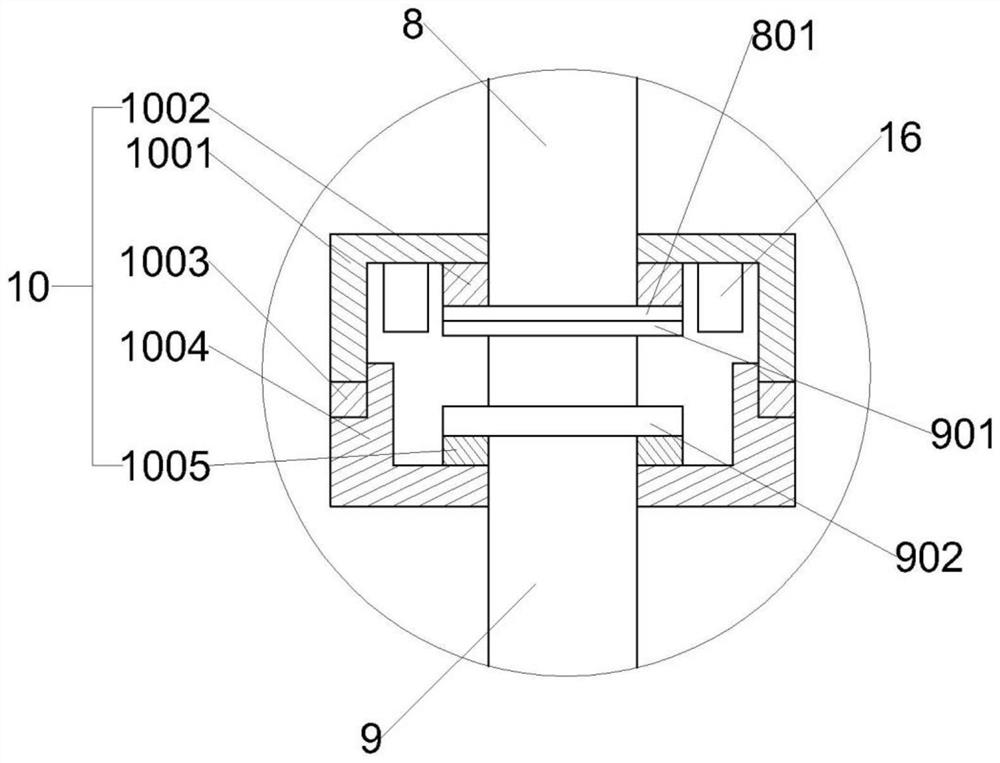

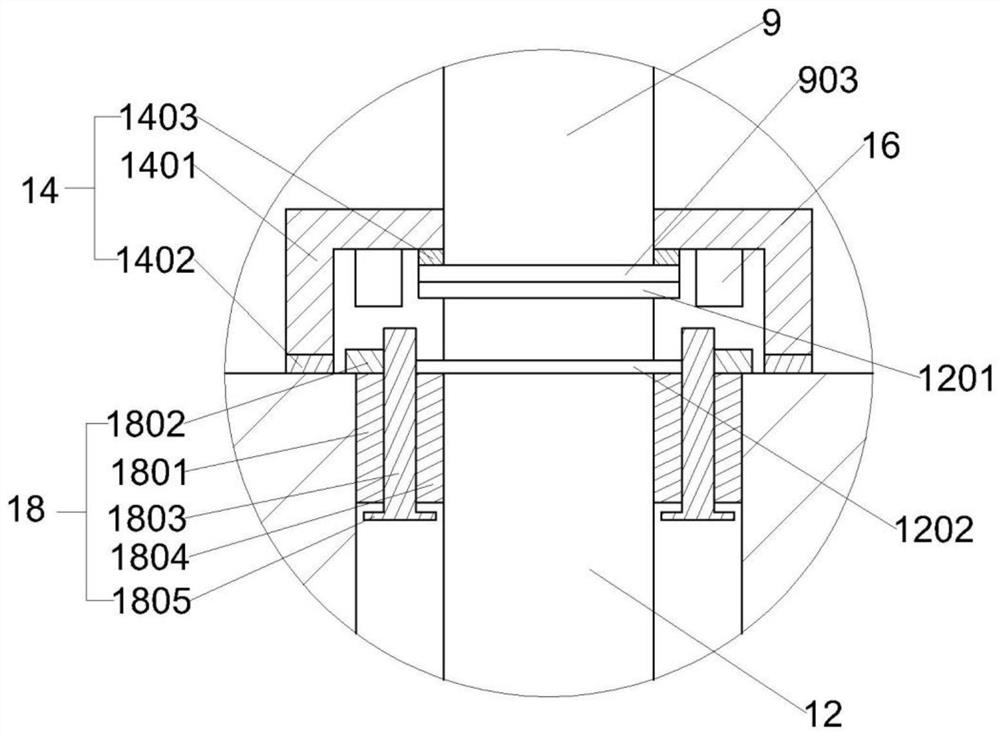

[0033] refer to Figure 1-6 As shown, this embodiment provides an intelligent underground gas extraction device for coal mines, including a bracket 1, a gas-liquid separator 2 is fixedly connected to the bracket 1, a water tank 3 is connected to the bottom of the gas-liquid separator 2, and the gas-liquid separator 2. The outlet end of the gas pump station 4 is connected to the gas pumping station 4. The outlet end of the gas pumping station 4 is connected to the gas collection box 5. The inlet end of the gas-liquid separator 2 is connected to the first pipeline 8. The first pipeline 8 is equipped with an intelligent valve 6. The first The end of the pipeline 8 away from the gas-liquid separator 2 is connected to the confluence end of the collecting pipe 9, and the diverging ends of the collecting pipe 9 are respectively connected to the extraction pipe 12, and the extraction pipe 12 extends into the borehole, and the outside of the extraction pipe 12 A fifth sealing structure...

Embodiment 2

[0056] refer to Figure 7As shown, the difference between the extraction device of this embodiment and the first embodiment is that a plugging assembly is sleeved on the outside of the extraction pipe 12, and the plugging assembly is located below the fifth sealing structure 18. The air bag 13 on the outside of the extraction pipe 12, the first passage 904 is opened in the side wall of the diversion end of the collecting pipe 9, the second passage 1203 is opened in the side wall of the extraction pipe 12, the first passage 904 communicates with the second passage 1203, The end of the first channel 904 away from the second channel 1203 is connected to the communication tube 15 , the end of the communication tube 15 away from the first channel 904 is connected to the pump body 11 , and the end of the second channel 1203 away from the first channel 904 is connected to the airbag 13 .

[0057] The pump body 11 is electrically connected with the controller, and the operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com