Method for preparing interdigital chip type miniature supercapacitor through 3D printing technology

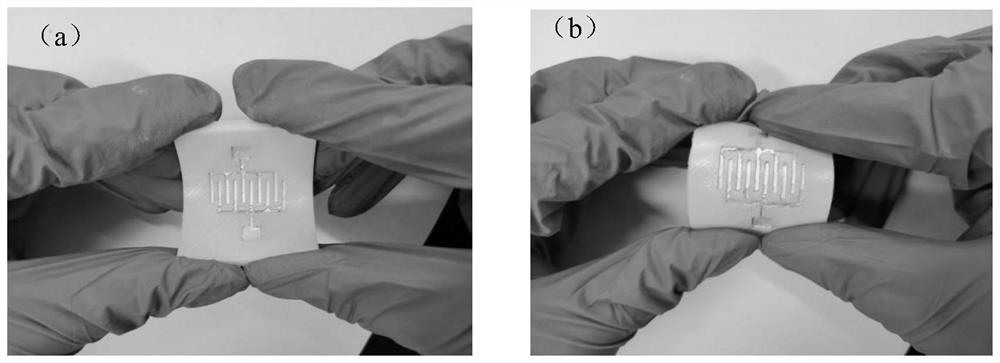

A supercapacitor and 3D printing technology, applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double layer capacitors, etc., can solve the problems of unsatisfactory mechanical properties of microcapacitor electrode active materials, and achieve good mechanical properties. The effect of increasing the load and increasing the capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing interdigitated chip-type micro-supercapacitors by 3D printing technology is provided, comprising the steps of:

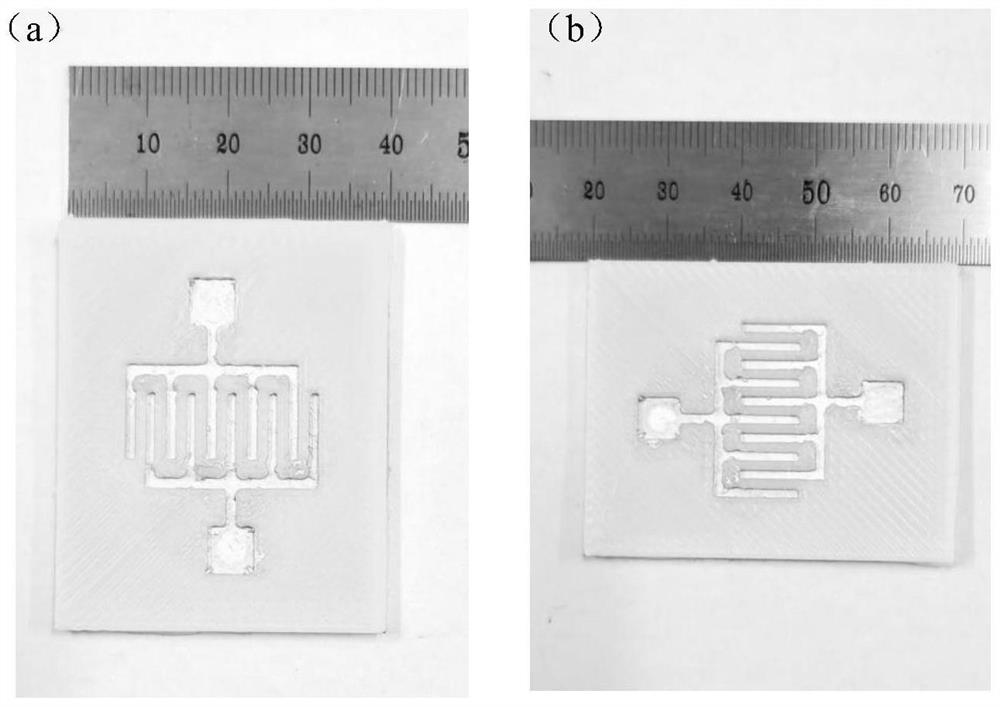

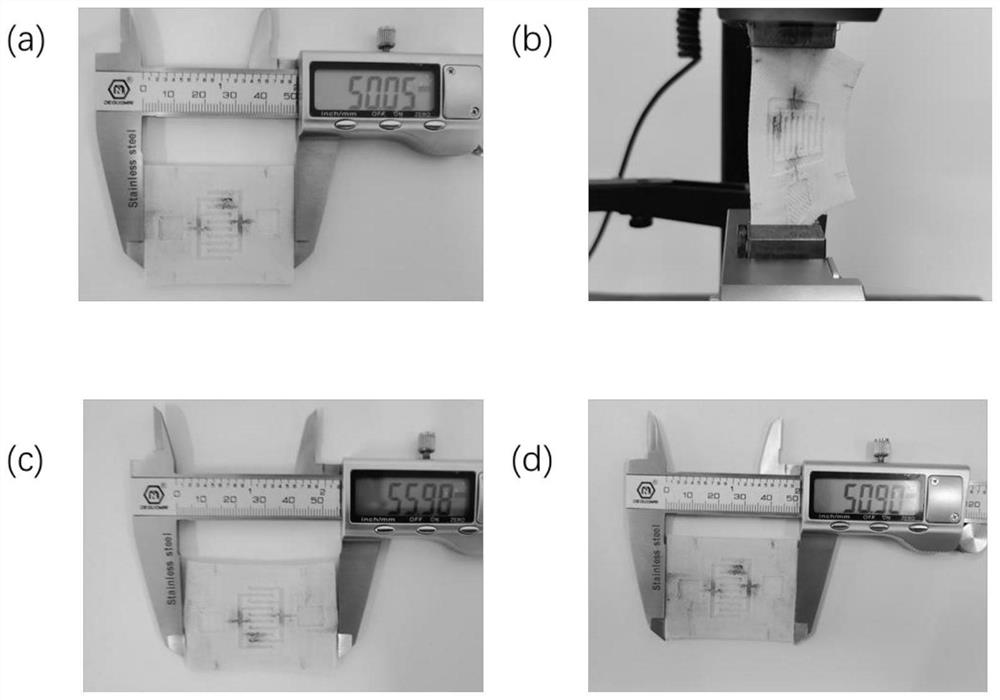

[0033] (1) Design of the base model: the bottom plate of the base is 3 mm thick, 50 mm long, and 40 mm wide. The electrode pattern groove is 0.5mm deep, and the electrode pattern is two interdigitated electrodes. The output end of each electrode is 4mm×4mm, and each electrode has five electrode fingers of 7.5mm×1.5mm. The spacing is 3mm. The distance between the electrode fingers and the other electrode is 1.5 mm.

[0034] (2) 3D printing of TPU electrodes: select commercial TPU filaments. Use 3D printing technology to print the mold. The nozzle temperature during printing is 150°C, the filling density is 100%, the filling pattern is grid, the layer height is 0.1mm, and the printing accuracy is 0.1mm. After the 3D printing process is finished, it is cooled at room temperature and removed from the substrate with a scraper to obtain an...

Embodiment 2

[0040] A method for preparing interdigitated chip-type micro-supercapacitors by 3D printing technology is provided, comprising the steps of:

[0041] (1) Design of the base model: the bottom plate of the base is 3 mm thick, 50 mm long, and 40 mm wide. The electrode pattern groove is 0.5mm deep, and the electrode pattern is two interdigitated electrodes. The output end of each electrode is 4mm×4mm, and each electrode has five electrode fingers of 7.5mm×1.5mm. The spacing is 3.5mm. The distance between the electrode fingers and the other electrode is 1.5mm.

[0042] (2) 3D printing of TPU electrodes: select commercial TPU filaments. Use 3D printing technology to print the mold. The nozzle temperature during printing is 150°C, the filling density is 100%, the filling pattern is grid, the layer height is 0.1mm, and the printing accuracy is 0.1mm. After the 3D printing process is finished, it is cooled at room temperature and removed from the substrate with a scraper to obtain a...

Embodiment 3

[0046] A method for preparing interdigitated chip-type micro-supercapacitors by 3D printing technology is provided, comprising the steps of:

[0047] (1) Design of the base model: the bottom plate of the base is 3 mm thick, 50 mm long, and 40 mm wide. The electrode pattern groove is 0.5mm deep, and the electrode pattern is two interdigitated electrodes. The output end of each electrode is 4mm×4mm, and each electrode has five electrode fingers of 7.5mm×2mm. The distance between the electrode fingers on the same side is 5mm. The distance between the electrode fingers and the other electrode is 0.5mm.

[0048] (2) 3D printing of TPU electrodes: select commercial TPU filaments. Use 3D printing technology to print the mold. The nozzle temperature during printing is 150°C, the filling density is 100%, the filling pattern is grid, the layer height is 0.1mm, and the printing accuracy is 0.1mm. After the 3D printing process is finished, it is cooled at room temperature and removed f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com