Preparation method of flexible stretchable miniature supercapacitor

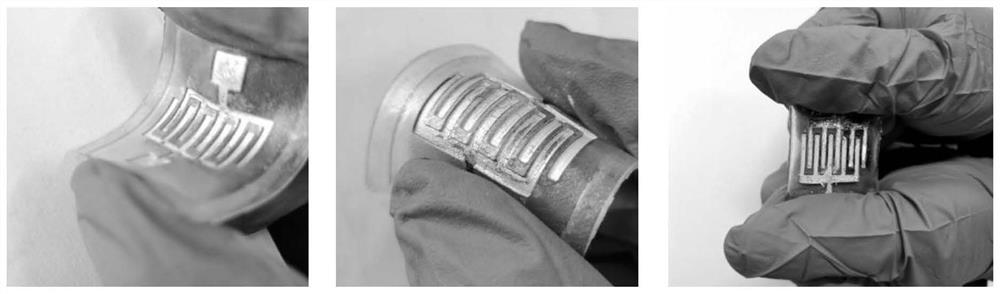

A supercapacitor, miniature technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor current collectors, etc., to achieve high production accuracy, good tensile strain, and increased load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

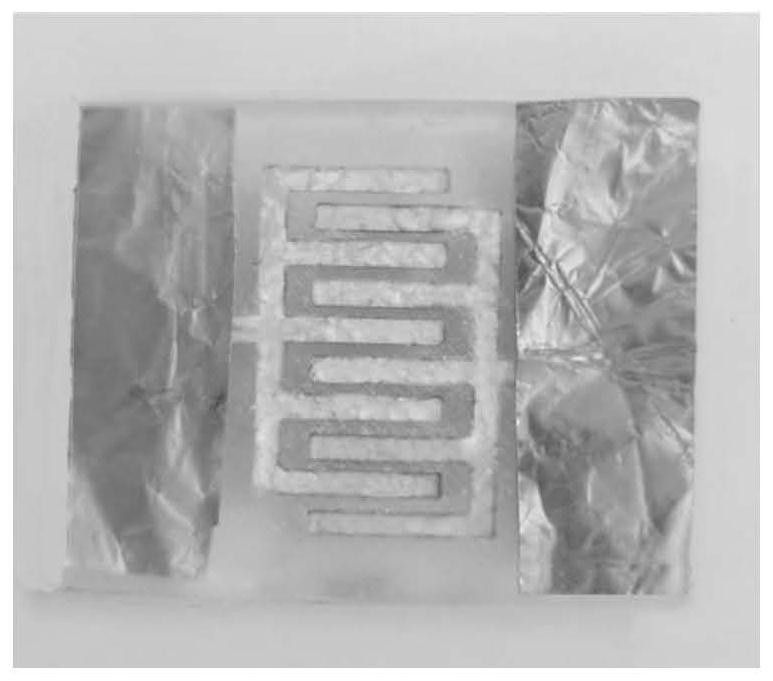

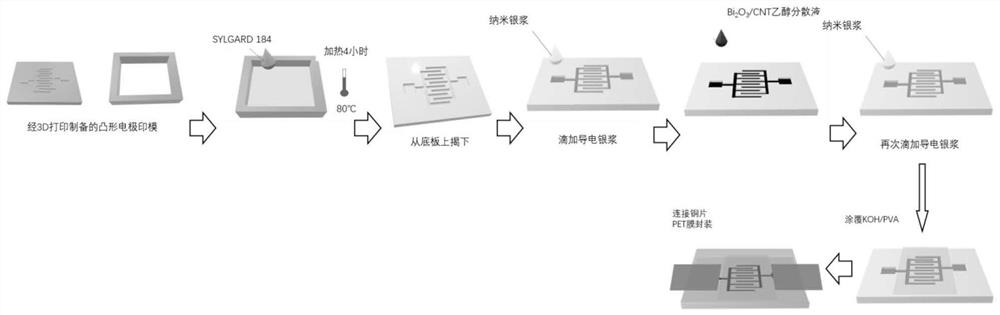

[0044] A method for preparing a flexible and stretchable micro-supercapacitor is provided, comprising the following steps:

[0045] (1) Use 3D modeling software to construct a mold model and an interdigitated electrode pattern. The size of the bottom plate is 50mm long, 40mm wide, and 3mm high. The protrusion height of the electrode pattern on the bottom plate is 0.5mm. The thickness of the outer wall is 4mm, the height is 10mm, and the outer contour size is the same as that of the bottom plate.

[0046] (2) Using 3D printing technology, select commercialized polylactic acid wire with a diameter of 1.75mm, the printing layer height is 0.1mm, the printing accuracy is 0.1mm, the filling type is grid, the filling density is 100%, and the printing temperature is 150 ℃, print out the bottom plate part and the outer wall part of the mold.

[0047] (3) The outer wall of the mold is combined with the bottom plate, inject 6g of mixed Sylgard-184 silicone rubber and cross-linking agent...

Embodiment 2

[0058] A method for preparing a flexible and stretchable micro-supercapacitor is provided, comprising the following steps:

[0059] (1) Use 3D modeling software to construct the mold model and electrode pattern. The size of the bottom plate is 50 mm in length, 40 mm in width and 3 mm in height, and the protrusion height of the electrode pattern on the bottom plate is 0.5 mm. The thickness of the outer wall is 4mm, and the height is 10mm. The outer contour size is the same as that of the bottom plate.

[0060] (2) Using 3D printing technology, select commercialized polylactic acid wire with a diameter of 1.75mm, the printing layer height is 0.1mm, the printing accuracy is 0.1mm, the filling type is grid, the filling density is 100%, and the printing temperature is 150 ℃, print out the bottom plate part and the outer wall part of the mold.

[0061] (3) The outer wall of the mold is combined with the bottom plate, inject 6g of mixed Sylgard-184 silicone rubber and cross-linking ...

Embodiment 3

[0068] A method for preparing a flexible and stretchable micro-supercapacitor is provided, comprising the following steps:

[0069] (1) Use 3D modeling software to construct the mold model and electrode pattern. The size of the bottom plate is 50 mm in length, 40 mm in width and 3 mm in height, and the protrusion height of the electrode pattern on the bottom plate is 0.5 mm. The thickness of the outer wall is 4mm, and the height is 10mm. The outer contour size is the same as that of the bottom plate.

[0070] (2) Using 3D printing technology, select commercialized polylactic acid wire with a diameter of 1.75mm, the printing layer height is 0.1mm, the printing accuracy is 0.1mm, the filling type is grid, the filling density is 100%, and the printing temperature is 150 ℃, print out the bottom plate part and the outer wall part of the mold.

[0071] (3) The outer wall of the mold is combined with the bottom plate, inject 5g of mixed Sylgard-184 silicone rubber and crosslinking a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com