Resistive random access memory and preparation method

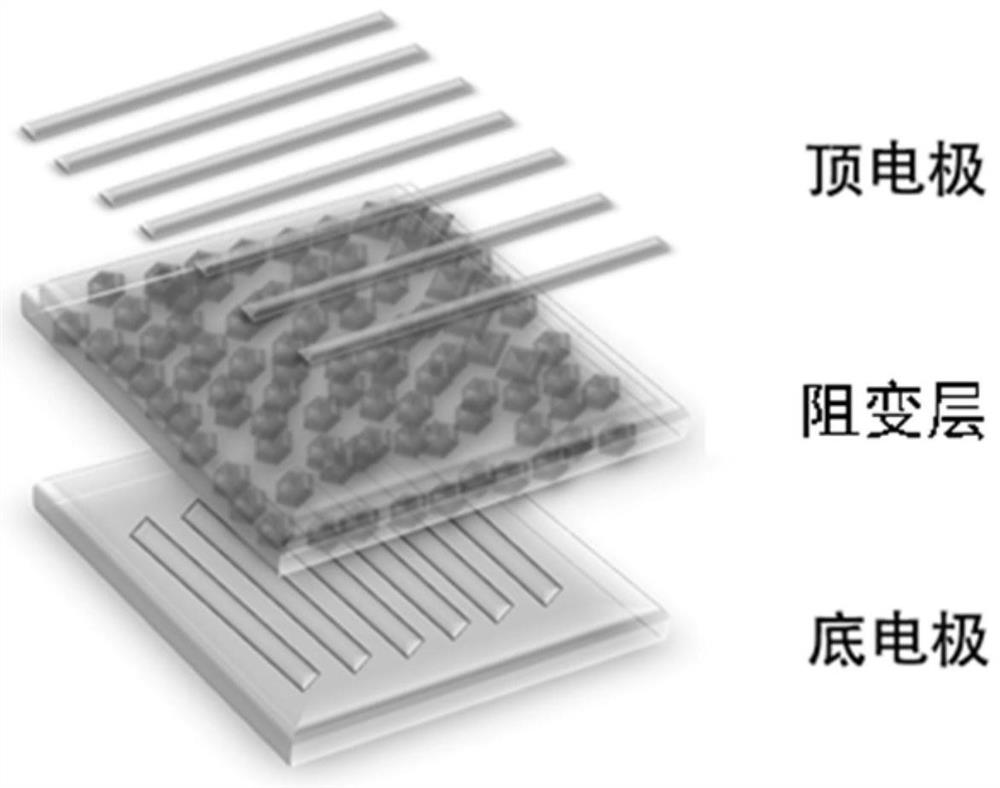

A technology of resistive variable memory and resistive layer, applied in the field of memory, can solve the problems of poor stability of resistive variable memory, achieve the effects of reducing energy, improving uniformity and stability, and reducing operating voltage and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Silver imidazole complex Ag(C 3 h 4 N 2 ) 2 NO 3 Preparation of the suspension:

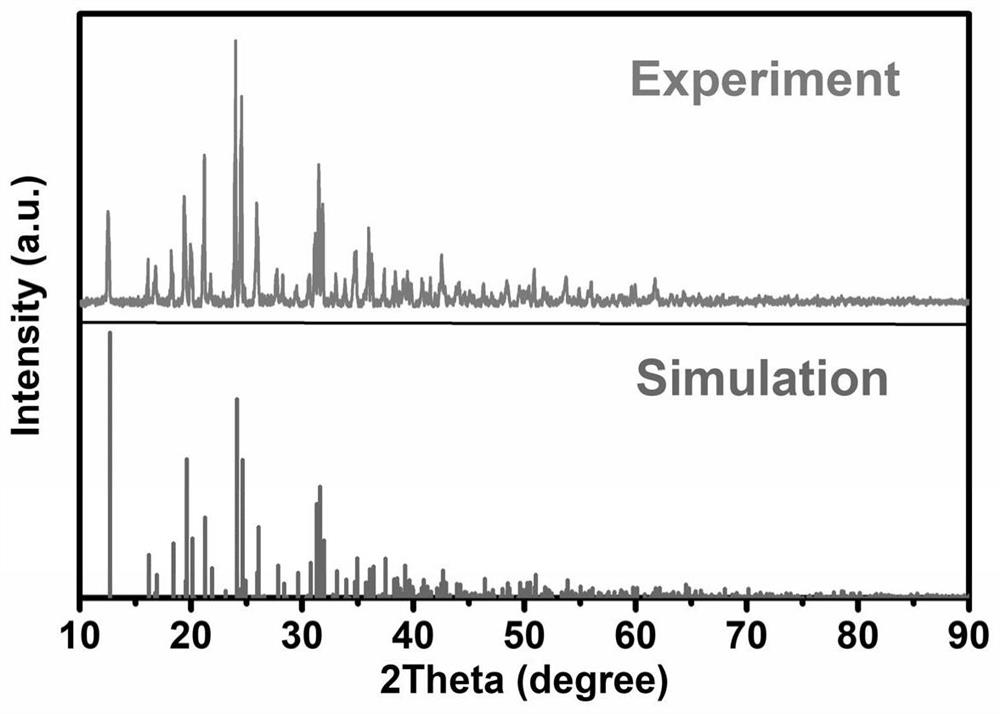

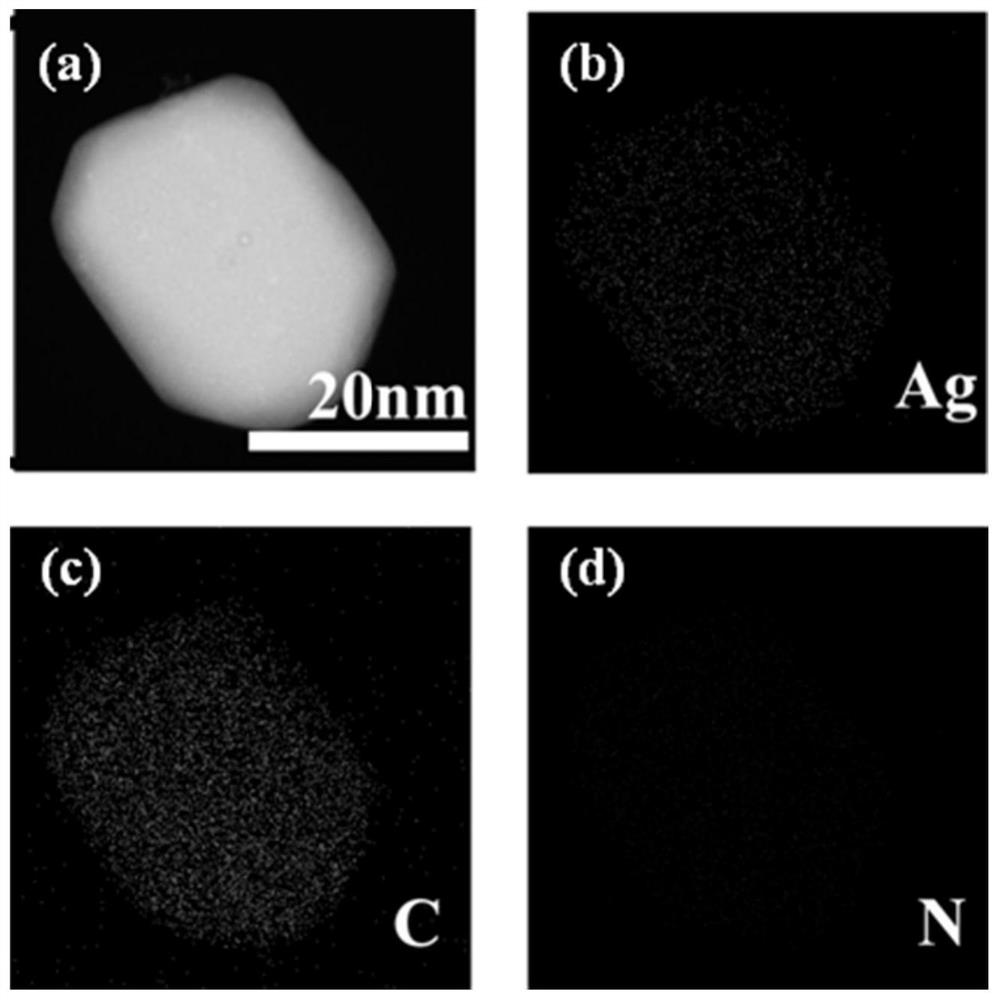

[0073] 0.005mol silver nitrate (AgNO 3 ) and 0.5 mol of imidazole were added to 100 mL of deionized water, stirred magnetically for 30 min, and then moved into a reaction kettle with a stainless steel outer shell and a tetrafluoroethylene lining, heated at 150 °C for 6 h at normal pressure, cooled to room temperature, and put the The solution is centrifugally washed with deionized water, and the deionized water of the last wash is retained to obtain 0.05mol / L silver imidazole complex Ag(C 3 h 4 N 2 ) 2 NO 3 Suspension. The prepared silver imidazole complex Ag(C 3 h 4 N 2 ) 2 NO 3 Orthorhombic crystal system, space group P2 1 2 1 2 1 , and its X-ray diffraction pattern is shown in figure 2 As shown, the transmission electron microscope image and its corresponding element Mapping image are as follows image 3 As shown, where (a) is a transmission electron microscope imag...

Embodiment 2

[0080] Silver imidazole complex Ag(C 4 h 6 N 2 ) 2 NO 3 Preparation of the suspension:

[0081] 0.001mol silver nitrate (AgNO 3 ) and 0.1mol 2-methylimidazole were added to 100mL deionized water, stirred by magnetic force for 30min, then moved into a reaction kettle with stainless steel shell and tetrafluoroethylene lining, heated at 100°C under normal pressure for 3h, and cooled to room temperature; The solution in the reactor is centrifugally washed with deionized water, and the deionized water is retained after the last washing to obtain 0.02mol / L silver imidazole complex Ag(C 4 h 6 N 2 ) 2 NO 3 Suspension.

[0082] Preparation of resistive memory:

[0083] The above-mentioned silver imidazole complex Ag(C 4 h 6 N 2 ) 2 NO 3 The suspension was added dropwise onto the ITO bottom electrode (the bottom of the ITO bottom electrode is provided with a glass substrate, wherein the thickness of the glass substrate is 0.5cm, and the thickness of the ITO bottom electr...

Embodiment 3

[0085] Silver imidazole complex Ag(C 5 h 6 N 2 ) 4 NO 3 Preparation of the suspension:

[0086] 0.05mol silver nitrate (AgNO 3 ) and 2.5mol 2-ethylimidazole were added to 100mL deionized water, stirred by magnetic force for 30min, then moved into a reaction kettle with stainless steel shell and tetrafluoroethylene lining, heated at 120°C under normal pressure for 6h, and cooled to room temperature; The solution in the reactor is centrifugally washed with deionized water, and the deionized water is retained after the last washing to obtain 0.05mol / L silver imidazole complex Ag(C 5 h 6 N 2 ) 4 NO 3 Suspension.

[0087] Preparation of resistive memory:

[0088] The above-mentioned silver imidazole complex Ag(C 5 h 6 N 2 ) 4 NO 3 The suspension was added dropwise onto the ITO bottom electrode (the bottom of the ITO bottom electrode is provided with a glass substrate, wherein the thickness of the glass substrate is 0.5cm, and the thickness of the ITO bottom electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com