Multifunctional oven

A multi-functional, oven technology, applied in baking devices, roasters/barbecue grids, heating devices, etc., can solve the problems of low heating efficiency, difficult to meet safety standards, high surface temperature, and reduce intermediate heat transfer. Medium, high heating efficiency, high heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

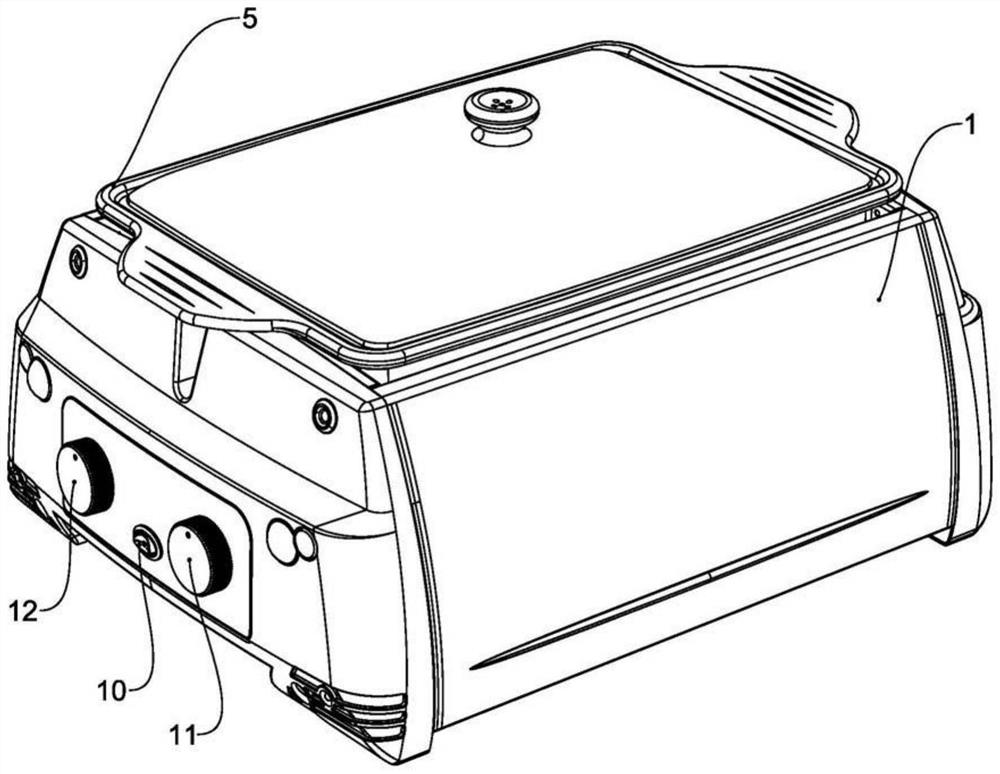

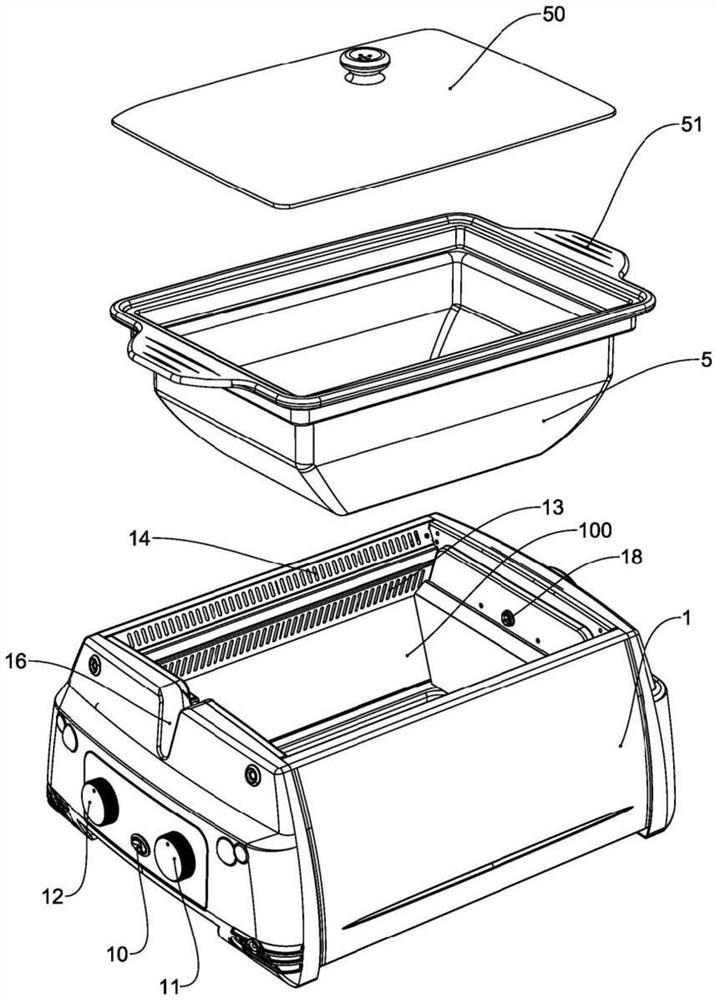

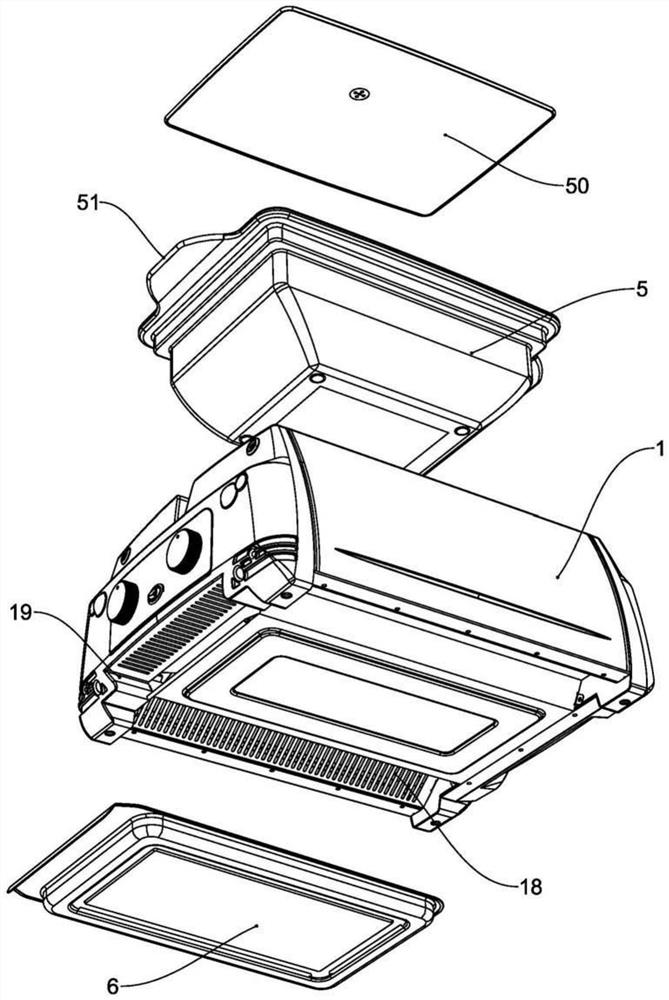

[0028] like Figure 1 to Figure 7As shown, the multifunctional oven of this embodiment includes a furnace body assembly 1, an electric control assembly, and a heating pot 5. The furnace body assembly 1 encloses a heating chamber 100 with an upper opening, and the bottom of the heating chamber 100 is provided with a The disassembled slag tray 6 can be used to receive food slag or particles dropped during food processing. The bottom of the furnace body assembly 1 is provided with a longitudinal slot 19, and the slag tray 6 is inserted into the slot 19 The electrical control assembly includes a switch 10, a thermostat 11, and a timer 12. In this embodiment, the switch 10 adopts a boat-shaped switch, and the thermostat 11 and the timer 12 adopt a mechanical knob type. The heating pot 5 includes a pot cover 50, the pot body of the heating pot 5 is provided with a handle 51, the heating pot 5 is erected at the top opening of the heating chamber 100, and the heating pot 5 connects th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com