High-temperature creep forming tooling for large cross-section titanium alloy profile and its application method

A titanium alloy and large-section technology, which is applied in the field of high-temperature creep forming tooling for large-section titanium alloy profiles, can solve the problems of uneven stress attenuation and unevenness of profiles, and affect the machining efficiency and quality of curvature components. Effects of high-temperature creep, improvement of forming accuracy, and improvement of temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

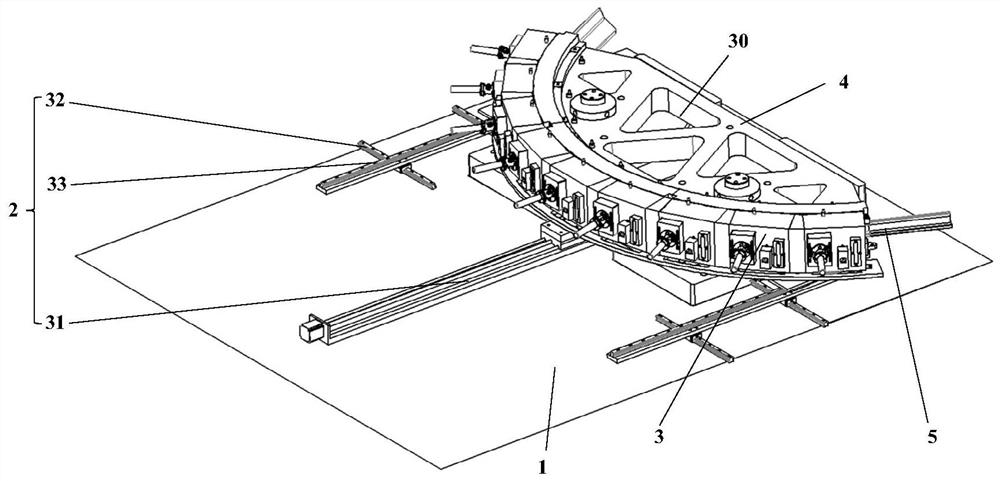

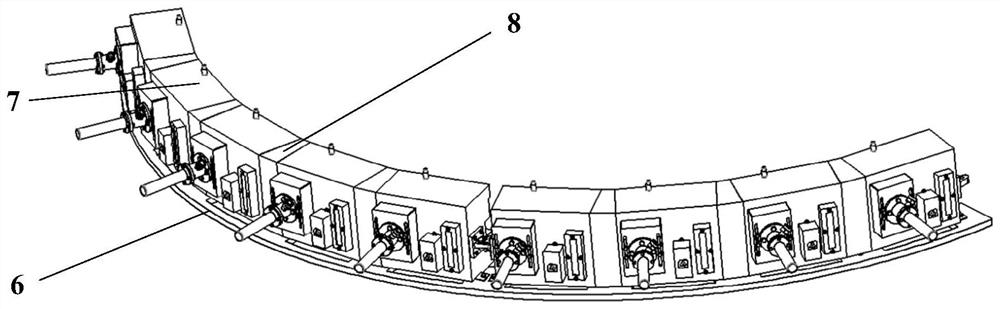

[0046] The present invention is described by taking a Y-shaped large-section titanium alloy profile as an example. It should be noted that the present invention is not only applicable to Y-shaped large-section titanium alloy profiles, but also applicable to large-section titanium alloy profiles of other shapes, which is not limited here.

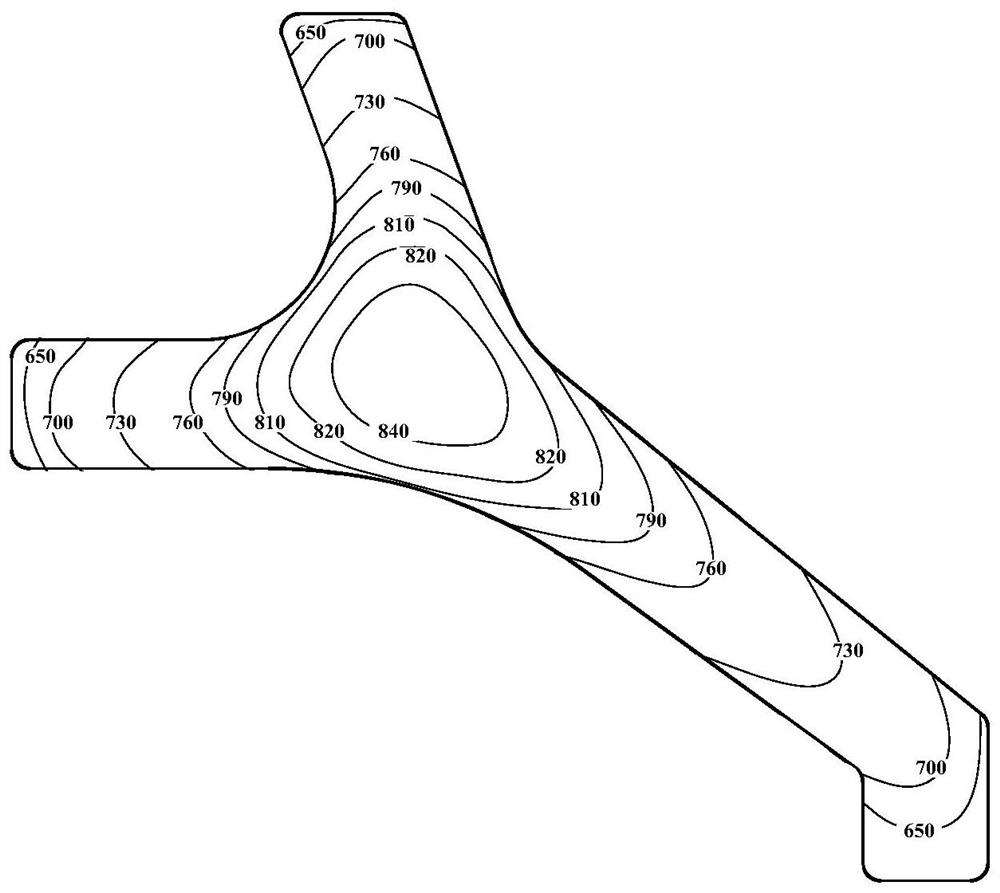

[0047] Due to the large and complex cross-sectional area of the Y profile, the temperature difference between the core and the outer surface of the profile is extremely large after the profile is energized. In order to ensure the temperature uniformity of the profile in the creep process, the present invention uses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com