Preparation method of germanium metal ball

A technology of metal balls and hemispheres, applied in the field of germanium metal, can solve problems such as extended production and processing cycles, increased demand for raw materials, and complicated production processes, and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

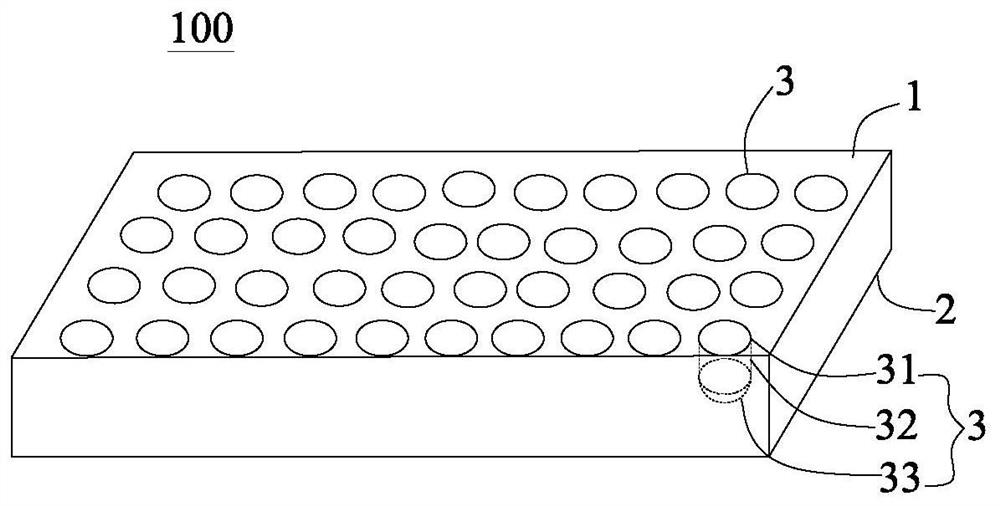

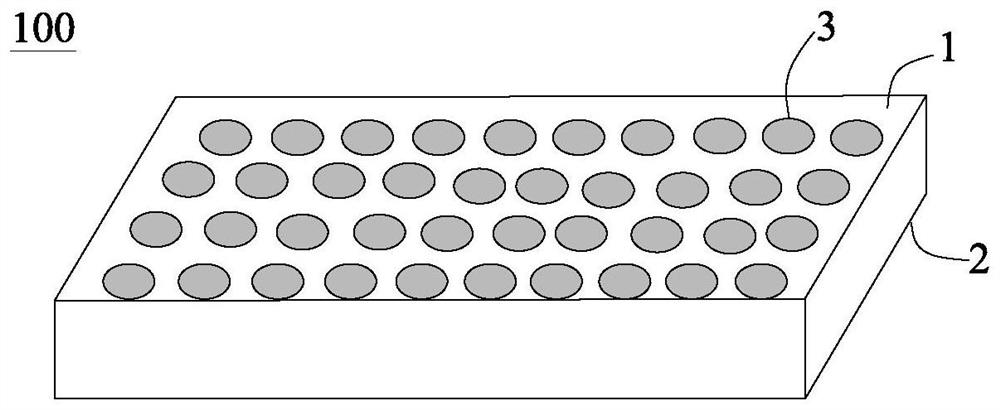

[0026] Firstly, the mold 100 for preparing germanium metal pellets of the present disclosure will be described.

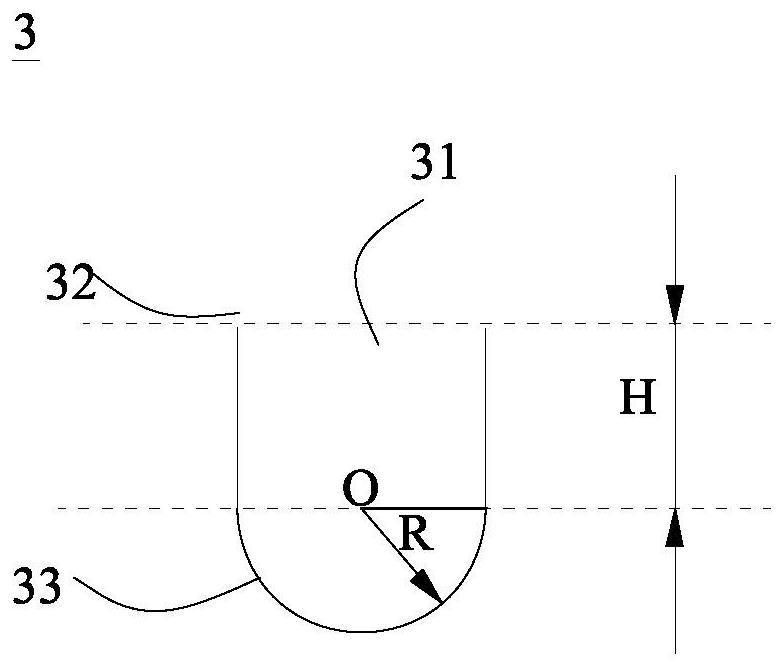

[0027] refer to Figure 1 to Figure 4 , the mold 100 is a plate body, the plate body has an upper surface 1 and a lower surface 2 opposite in the thickness direction; the plate body is provided with a U-shaped hole 3; the U-shaped hole 3 has an opening 31 located on the upper surface 1 of the plate body, from the plate A cylinder 32 extending downwards from the upper surface 1 of the body and a hemisphere 33 extending downwards from the cylinder 32; The faces are completely coincident in the thickness direction of the plate body. During the preparation process, based on germanium oxide, germanium is obtained through reduction reaction, the volume occupied by germanium is reduced, and at the same time, the gaps between the germanium oxide particles of the raw material are also eliminated, and then using the hemisphere 33 combined with the cooling volume expansion o...

Embodiment 1

[0046] Step 1, prepare the mold 100, the mold 100 is a graphite plate, the plate body has an upper surface 1 and a lower surface 2 opposite in the thickness direction, the plate body is provided with a U-shaped hole 3, and the U-shaped hole 3 has an upper surface 1 located on the plate body The opening 31 of the plate body, the cylinder 32 extending downward from the upper surface 1 of the plate body, and the hemisphere 33 extending downward from the cylinder 32, the radius R of the cylinder 32 is the same as the radius R of the hemisphere 33, and the radius R of the cylinder 32 The bottom surface and the top surface of the hemisphere 33 completely overlap in the thickness direction of graphite, the height H of the cylinder 32 is 6mm, the radius R of the cylinder 32 is 4mm, the gray scale of the graphite plate is lower than 20ppm, and the thickness of the plate is 20mm;

[0047] Step 2, spread the germanium oxide on the mold 100 so that it fills the plurality of U-shaped holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com