Protection tool for laser forging process formed by compounding laser cladding and laser shock

A laser shock and laser cladding technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that the protection tooling is difficult to meet the environmental conditions of laser cladding manufacturing, and achieves avoiding adverse effects and high discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

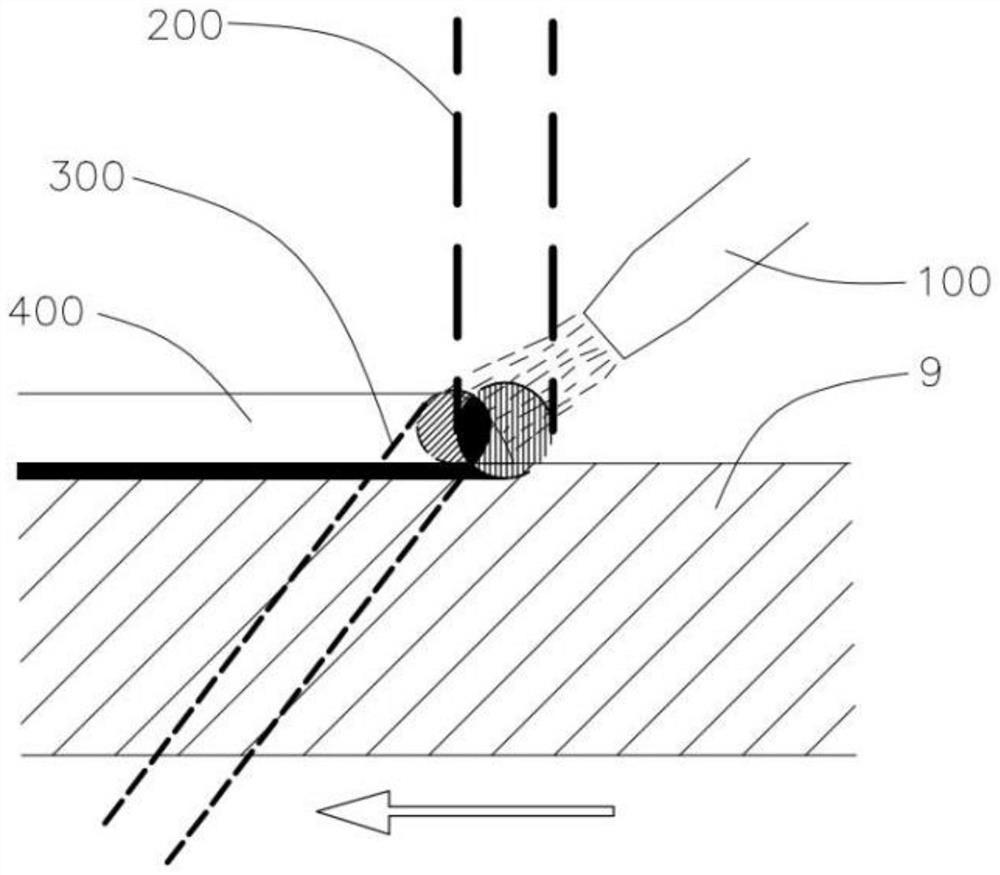

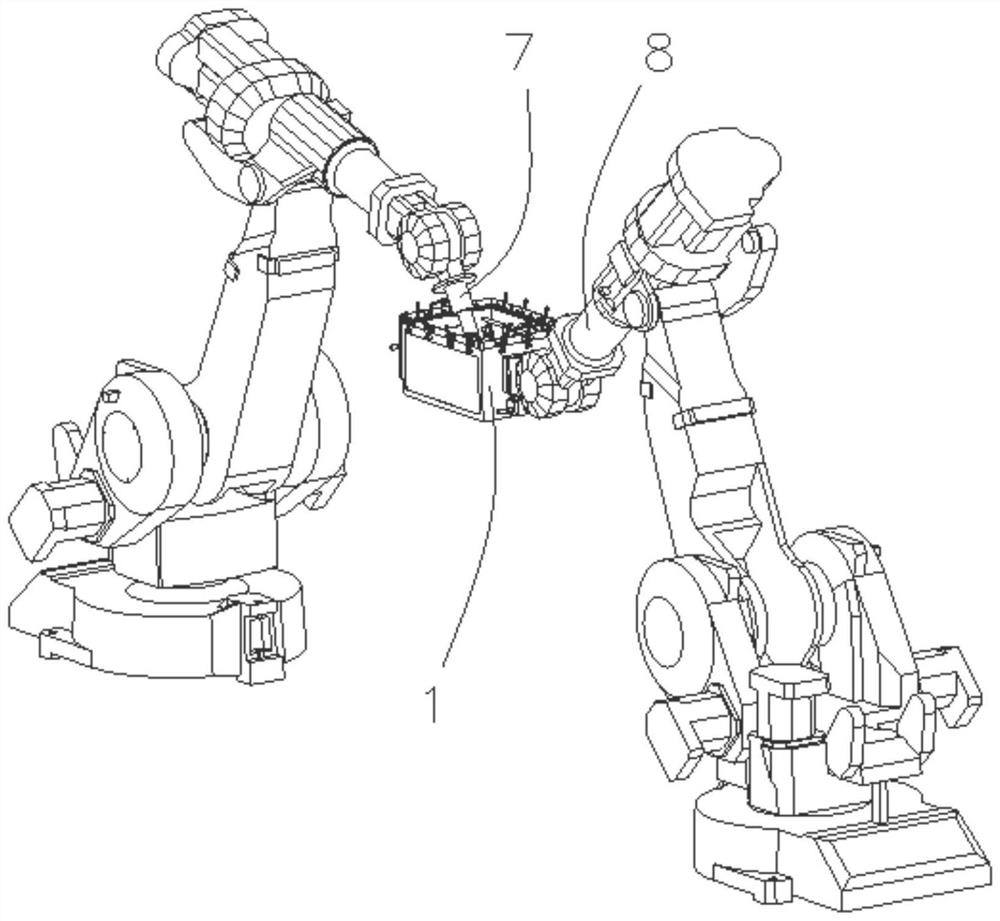

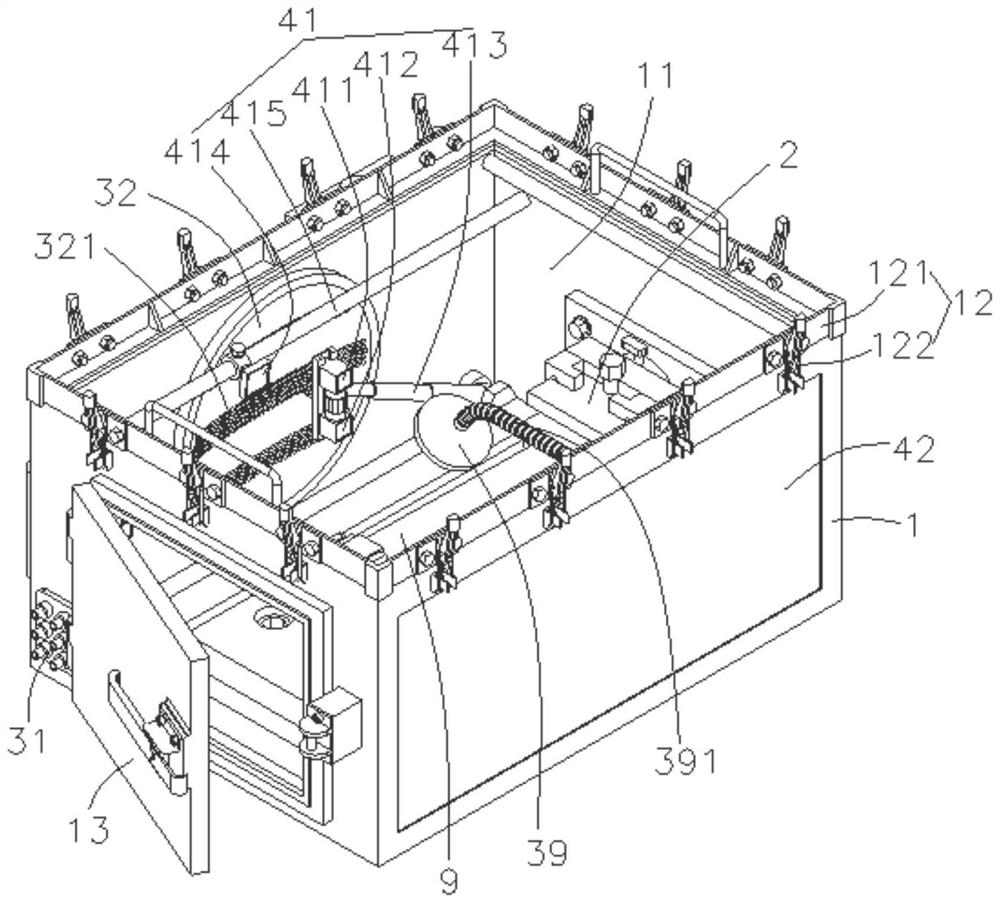

[0041] Such as Figure 1-7 As shown, a laser cladding and laser shock combined to form a protective tooling for the laser forging process, including an inert gas sealing box 1, a fixture 2, a gas path system, an optical path system, and a temperature adjustment system. The inert gas sealing box 1 There is an opening 11 on the top of the opening 11, and the opening 11 is covered with a sealing film (not shown in the figure) through the buckle connector 12. The cladding processing head 7 enters the inert gas sealed box 1 through the sealing film, and the cladding processing head 7 is provided with a powder nozzle 100 and a laser beam emitter for laser cladding. The sealing film of this embodiment and the cladding processing head 7 are sealed by bundling. The inert gas sealed box 1 is driven by a manipulator 8 relative to the cladding processing head 7 Move; the side of the inert gas sealed box 1 in this embodiment is also provided with a box door 13; the clamp 2 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com