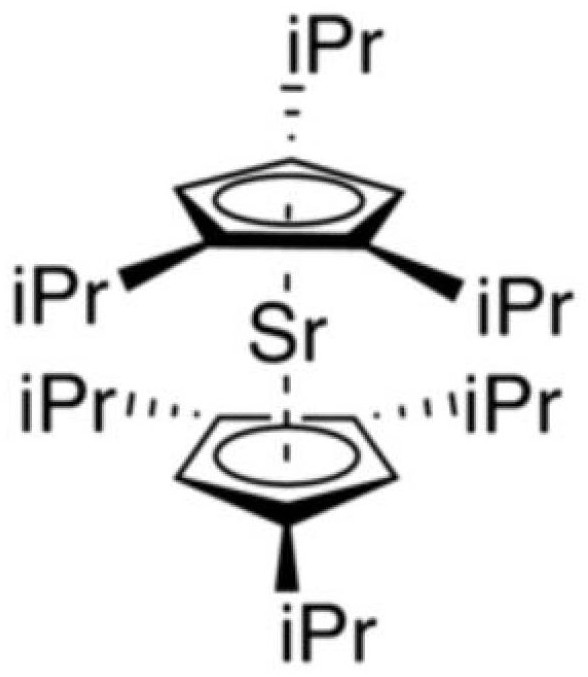

Preparation method of bis (triisopropyl cyclopentadienyl) strontium

A technology of triisopropylcyclopentadiene and propylcyclopentadiene is applied in the field of preparation of bis(triisopropylcyclopentadienyl) strontium, and can solve the problems of complicated process operation, difficult purification and high cost problems, to achieve the effect of high metal purity, avoid solvent molecule coordination, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

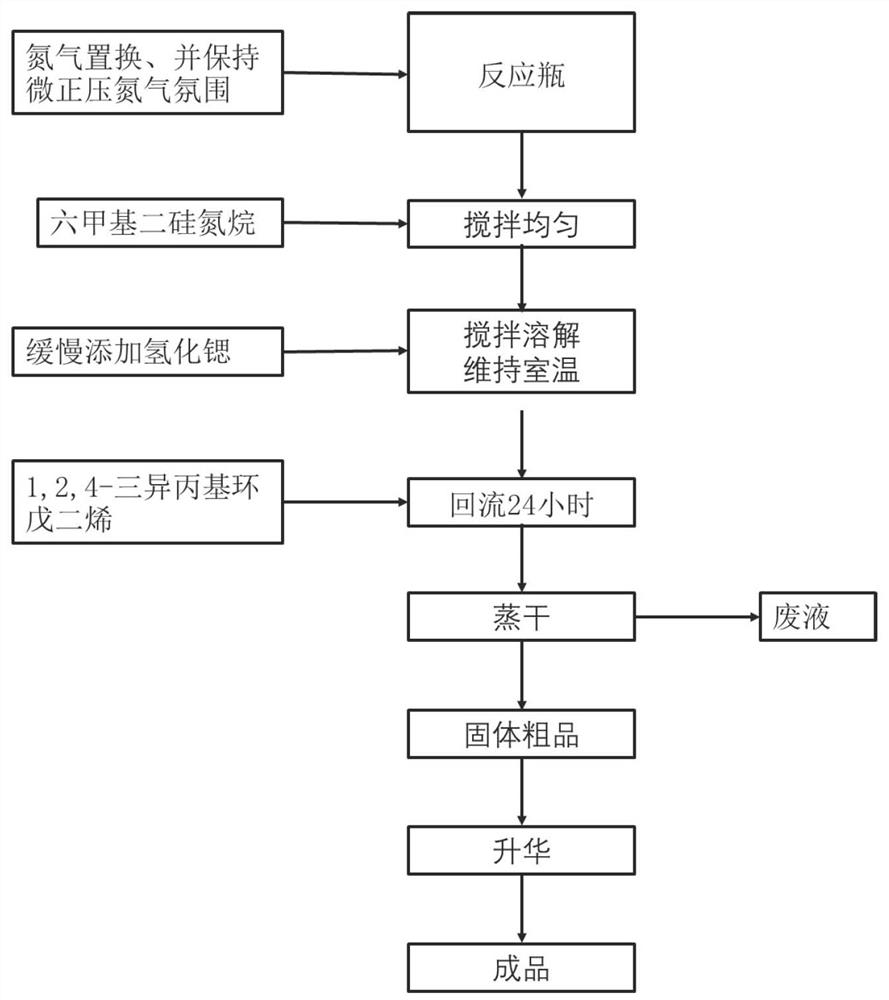

Method used

Image

Examples

Embodiment 1

[0032] Under nitrogen protection, add 200 mL of hexamethyldisilazane to a 500 mL reaction flask, start stirring, slowly add 8.96 g of strontium hydride solid powder into the reaction flask through a solid injector, stir to dissolve, and dissolve 48.01 g of 1 , 2,4-triisopropylcyclopentadiene was slowly added dropwise to the reaction flask, refluxed at 130 °C for 24 hours, and the obtained filtrate was evaporated to dryness under reduced pressure to obtain the crude product (off-white waxy solid), which was then sublimated under reduced pressure 40.44 g of bis(triisopropylcyclopentadienyl)strontium (white solid) were obtained, a yield of 86%.

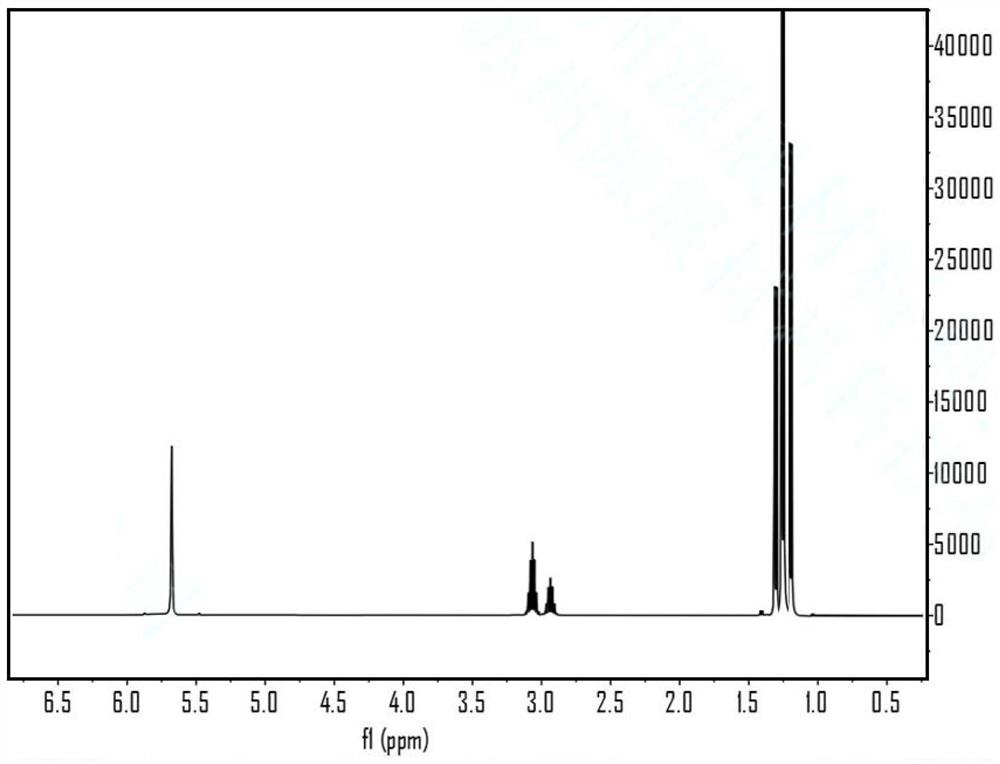

[0033] The product was characterized by NMR, as image 3 As shown, the NMR results are as follows:

[0034] 1 H NMR (500 MHz, C 6 D. 6 ) d (ppm): 5.79 (s, 4H, ring-CH), 3.0(m, 4H, CH), 2.94 (m, 2H, CH), 1.32(m, 36H, CH 3 ).

[0035] The metal purity of the sample was tested by inductively coupled plasma optical emission spectromete...

Embodiment 2

[0037]Under nitrogen protection, add 200 mL of hexamethyldisilazane to a 500 mL reaction flask, start stirring, slowly add 8.96 g of strontium hydride solid powder into the reaction flask through a solid injector, stir to dissolve, and dissolve 48.41 g of 1, 2,4-Triisopropylcyclopentadiene was slowly added dropwise to the reaction flask, refluxed at 130 °C for 24 hours, the obtained filtrate was evaporated to dryness under reduced pressure to obtain the crude product (off-white waxy solid), and then obtained by sublimation under reduced pressure 40.31 g of strontium bis(triisopropylcyclopentadienyl) (white solid), 85% yield.

[0038] The metal purity of the sample was tested by ICP-OES, and the results showed that the metal purity of the sample was 5N.

Embodiment 3

[0040] Under nitrogen protection, add 200 mL of hexamethyldisilazane to a 500 mL reaction flask, start stirring, slowly add 8.96 g of strontium hydride solid powder into the reaction flask through a solid injector, stir to dissolve, and dissolve 48.01 g of 1, 2,4-Triisopropylcyclopentadiene was slowly added dropwise to the reaction flask, refluxed at 130°C for 48 hours, and the obtained filtrate was evaporated to dryness under reduced pressure to obtain the crude product (off-white waxy solid), which was then obtained by sublimation under reduced pressure 40.71 g of strontium bis(triisopropylcyclopentadienyl) (white solid), 87% yield.

[0041] The metal purity of the sample was tested by ICP-OES, and the results showed that the metal purity of the sample was 5N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com